Keeping products fresh is a major hurdle for food producers today. Using a modified atmosphere packaging machine (map) changes the game by swapping normal air for special gas mixes. This process effectively slows down spoilage in fresh meat, seafood, and even delicate baked goods.

Replacing ambient air with a nitrogen–carbon-dioxide blend stops microbial growth. It prevents oxidation that often turns meat gray or makes fats go rancid. Modern systems provide the precision needed to keep every tray consistent and safe.

Proper film specs are vital to keep those protective gases inside the container. This technology protects the natural flavor and vibrant color of your goods. When you lower waste and extend shelf life, you quickly see a high ROI for your business.

Key Takeaways

- Extend shelf life significantly by replacing ambient air.

- Reduce food waste through customized gas blends.

- Maintain natural product appearance, color, and taste.

- Select correct film barrier properties for your specific product.

- Boost long-term profitability with a clear return on investment.

- Protect items like meat and seafood from rapid oxidation.

Understanding Modified Atmosphere Packaging Technology (MAP)

Modified Atmosphere Packaging (MAP) technology has revolutionized the way food products are preserved and presented to consumers. By altering the atmosphere surrounding the food, MAP technology extends shelf life, maintains product freshness, and enhances overall quality.

MAP involves replacing the air inside a food tray or package with a controlled mix of gases, typically nitrogen, carbon dioxide, and oxygen. This gas mixture is carefully selected based on the specific requirements of the food product being packaged.

What is Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) is a technique used to extend the shelf life of food products by modifying the atmosphere surrounding them. This is achieved by displacing the air in the package with a gas mixture that inhibits the growth of microorganisms and slows down the oxidation process.

The gas mixture used in MAP depends on the type of food product. For example, high-oxygen mixes are often used for red meats to maintain their color, while low-oxygen mixes are used for products like bakery goods to prevent staling.

How MAP Extends Shelf Life of Food Products

MAP extends the shelf life of food products by controlling the atmosphere around them. By reducing oxygen levels, MAP inhibits the growth of aerobic bacteria and mold, thereby slowing down the spoilage process.

Additionally, MAP helps maintain the quality of food products by preventing moisture loss, reducing the risk of contamination, and minimizing the effects of ethylene production, which can lead to over-ripening.

Key benefits of MAP include:

- Extended shelf life

- Improved product quality

- Reduced food waste

- Enhanced product presentation

Controlled Atmosphere Packaging vs Equilibrium Modified Atmosphere Packaging (EMAP)

Controlled Atmosphere Packaging (CAP) and Equilibrium Modified Atmosphere Packaging (EMAP) are two related but distinct concepts within the broader category of MAP.

CAP involves maintaining a controlled atmosphere within a sealed package or storage container, where the gas composition is continuously monitored and adjusted to maintain optimal levels.

EMAP, on the other hand, involves creating a modified atmosphere within a package that is allowed to reach equilibrium with the surrounding environment. This approach is often used for fresh produce, where the packaging film is designed to allow for a gradual exchange of gases until an equilibrium is reached.

Understanding the differences between CAP and EMAP is crucial for selecting the most appropriate MAP solution for specific food products.

The 5 Main Types of Modified Atmosphere Packaging Machines (MAP)

The modified atmosphere packaging (MAP) industry has evolved to offer a range of machinery catering to diverse food packaging needs. These machines are designed to modify the atmosphere around food products, thereby extending shelf life and maintaining freshness. The choice of MAP machine depends on the type of food product, production volume, and packaging requirements.

MAP Tray Sealer for Produce and Fresh Foods

MAP tray sealers are widely used for packaging fresh produce, meats, and ready-to-eat meals. These machines seal trays with a film, creating a modified atmosphere that preserves the product. Y-Fang Group offers advanced MAP packaging solutions, including the ET-55 model, designed to enhance efficiency and maintain high-quality seals.

The ET-55 tray sealer is particularly suitable for packaging fresh produce, as it ensures a consistent seal and maintains the integrity of the product. This is crucial for products like fresh vegetables and fruits, where maintaining the right atmosphere is key to extending shelf life.

Thermoforming Machines for High-Volume MAP Operations

Thermoforming machines are ideal for high-volume MAP operations. They form trays from rollstock film, fill them with product, and then seal the trays with a top film. This process is highly efficient and is commonly used for packaging meats, cheeses, and prepared foods.

These machines offer flexibility in terms of tray size and shape, allowing manufacturers to package a variety of products. The thermoforming process also ensures a tight seal, which is essential for maintaining the modified atmosphere.

Vacuum Chamber Machines with Gas Flushing Capability

Vacuum chamber machines with gas flushing capability are used for products that require a high level of oxygen removal. These machines evacuate the air from the package and then flush it with a gas mix before sealing. This process is particularly useful for packaging coffee, nuts, and other sensitive products.

The gas flushing capability ensures that the package is filled with the desired gas mix, which helps in preserving the product’s freshness and flavor.

MAP Flow Wrapping Equipment for Bakery and Snacks

MAP flow wrapping equipment is commonly used for packaging bakery products and snacks. These machines wrap products in a film, creating a modified atmosphere around them. The flow wrapping process is highly efficient and is suitable for high-speed production lines.

Flow wrapping equipment can be configured to use different types of films and gas mixes, making it versatile for various bakery and snack products.

Gas Flushing Packaging Systems: How They Work

Gas flushing is a sophisticated process integral to MAP, involving the displacement of oxygen with a specific blend of gases tailored to the product’s requirements. This process is critical in maintaining the quality and extending the shelf life of packaged products.

The 2 Main Gas Flushing Systems Explained

There are primarily two types of gas flushing systems used in MAP technology: continuous gas flushing and one-shot gas flushing. Continuous gas flushing involves a steady flow of gas into the packaging, maintaining a consistent atmosphere. This method is particularly useful for products requiring a high level of gas purity.

One-shot gas flushing, on the other hand, involves a single flush of gas into the package, which is then sealed. This method is efficient for products with less stringent gas composition requirements.

Gas Flushing in Vacuum Packaging Applications

In vacuum packaging, gas flushing is often used in conjunction with vacuum to create an optimal atmosphere. After the air is evacuated, a specific gas mix is flushed into the package to enhance product preservation. Nitrogen flushing is commonly used for this purpose, especially for snacks and bakery products, to prevent staleness and maintain crispness.

Gas Flushing in Flow Pack Machines

Flow pack machines utilize gas flushing to create a modified atmosphere around the product. These machines are widely used in the packaging of bakery items, snacks, and other food products. The gas flushing capability of flow pack machines ensures that the product is packaged in an environment that inhibits the growth of bacteria and other microorganisms, thereby extending shelf life.

By understanding how gas flushing packaging systems work and their applications in various packaging technologies, manufacturers can make informed decisions about the most suitable MAP solutions for their products.

Step 1: Selecting the Right Gas Mix for Your Product

The right gas blend is essential for maintaining the quality and freshness of packaged food products. The choice of gas mix is critical and varies significantly by product category. Different foods require different gas compositions to achieve the desired shelf life and quality.

For instance, the gas mix for packaging fresh red meat differs from that used for seafood or bakery products. Understanding the specific needs of your product is crucial for selecting the appropriate gas blend.

Nitrogen Flushing for Food Packaging Applications

Nitrogen flushing is a widely used technique in food packaging, particularly for products that are sensitive to oxygen. By displacing oxygen with nitrogen, the oxidation process is slowed down, thereby extending the shelf life of the product.

Nitrogen flushing is commonly used for packaging snacks, nuts, and dried foods. It helps prevent staleness and maintains the product’s texture.

Case-Ready Packaging Gas Mix for Fresh Red Meat

Case-ready packaging for fresh red meat requires a specific gas mix that maintains the meat’s color and freshness. A typical gas mix for red meat includes a combination of oxygen, carbon dioxide, and sometimes nitrogen.

The high oxygen levels help maintain the red color of the meat, while carbon dioxide inhibits bacterial growth. For example, a common gas mix for packaging fresh beef is 70-80% oxygen and 20-30% carbon dioxide.

CO2 Packaging for Extended Shelf Life

Carbon dioxide (CO2) is used in packaging to inhibit the growth of bacteria and mold, thereby extending the shelf life of perishable products. CO2 packaging is commonly used for products like bakery goods, dairy products, and fresh produce.

The concentration of CO2 can vary depending on the product. For example, CO2 packaging for fresh produce like strawberries may use a mix that includes a higher percentage of CO2 to prevent mold growth.

Custom Gas Blends for Specific Food Categories

Different food categories require custom gas blends tailored to their specific needs. For example, pork cuts may require a gas mix of 60-70% O2 and 30-40% CO2, while shrimp packaging might use a mix of 40% CO2 and 60% N2.

Understanding the specific requirements of your product category is crucial for determining the optimal gas blend. Working with a gas supplier or packaging expert can help in developing a custom gas mix that meets your product’s needs.

Some key considerations when selecting a gas mix include the type of product, its sensitivity to oxygen and moisture, and the desired shelf life. By choosing the right gas blend, manufacturers can significantly improve the quality and freshness of their packaged products.

- Identify the product category and its specific gas mix requirements.

- Consider the role of nitrogen, CO2, and oxygen in the gas mix.

- Work with experts to develop a custom gas blend if necessary.

- Test and validate the chosen gas mix for optimal results.

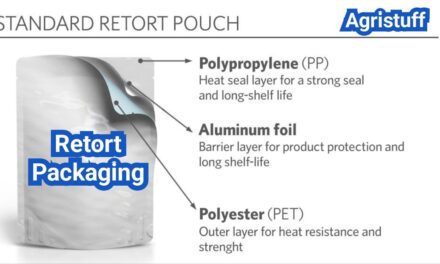

Step 2: Choosing Film Specifications for MAP Applications

Selecting the right film specifications is crucial for effective Modified Atmosphere Packaging (MAP) applications. The film used in MAP plays a critical role in maintaining the internal atmosphere and ensuring the product’s shelf life. High-barrier films are essential to prevent gas exchange and maintain the desired atmosphere within the package.

The choice of film depends on the product’s requirements and shelf life goals. Different products have varying needs in terms of gas barrier properties, moisture resistance, and mechanical strength. Understanding these requirements is key to selecting the appropriate film for MAP applications.

Understanding Oxygen Transmission Rate (OTR) Film for MAP

Oxygen Transmission Rate (OTR) is a critical parameter for films used in MAP. OTR measures the rate at which oxygen passes through the film. Products that are sensitive to oxygen, such as fresh meat and bakery goods, require films with low OTR to prevent spoilage and maintain freshness.

Low OTR films are designed to minimize oxygen ingress, thereby extending the shelf life of oxygen-sensitive products. The choice of OTR depends on the specific product and its storage conditions.

“The right OTR film can significantly extend the shelf life of products by controlling the oxygen levels within the package.”

— Packaging Expert

Moisture Vapor Transmission Rate (MVTR) Packaging Requirements

Moisture Vapor Transmission Rate (MVTR) is another important factor in MAP film selection. MVTR measures the film’s ability to prevent moisture transfer between the product and the external environment. Products that are sensitive to moisture, such as dried foods and snacks, require films with appropriate MVTR to maintain their texture and freshness.

| Product Category | Required MVTR | Film Type |

|---|---|---|

| Dried Foods | Low MVTR | Barrier Film |

| Fresh Produce | Moderate MVTR | Permeable Film |

| Snacks | Low MVTR | Barrier Film |

EVOH Barrier Film for Food Packaging Protection

EVOH (Ethylene-Vinyl Alcohol) barrier films are widely used in MAP for their excellent gas barrier properties. EVOH films provide a high barrier to oxygen, making them ideal for packaging oxygen-sensitive products. They are often used in multi-layer film structures to achieve the desired balance of barrier properties and mechanical strength.

EVOH barrier films are particularly effective in applications where high oxygen barrier is required, such as in the packaging of fresh red meat and processed meats.

Matching Film Properties to Product Shelf Life Goals

The ultimate goal of MAP is to extend the shelf life of the product while maintaining its quality. To achieve this, it’s essential to match the film properties with the product’s shelf life goals. This involves considering factors such as OTR, MVTR, and the product’s sensitivity to gas and moisture.

By carefully selecting the film specifications based on the product’s requirements, manufacturers can optimize their MAP applications and achieve the desired shelf life and product quality.

Step 3: Understanding Modified Atmosphere Packaging Equipment Components

To achieve optimal results with Modified Atmosphere Packaging (MAP), understanding the equipment components is crucial. Modern MAP packaging equipment integrates various components, including gas mixing systems, heat sealing technology, and automated loading systems, to ensure efficient and high-quality packaging.

Gas Mixing and Delivery Systems

The gas mixing and delivery system is a critical component of MAP equipment. It is responsible for creating the precise gas blend required for the specific product being packaged. Gas mixing systems typically include gas cylinders, mixing tanks, and control units that regulate the gas composition.

The accuracy of the gas mix is vital for maintaining the desired atmosphere within the package, directly impacting the product’s shelf life and quality.

Heat Seal and Sealing Technology

Heat sealing technology is another essential component, as it ensures that the package is sealed properly to maintain the modified atmosphere. The sealing process involves applying heat and pressure to the packaging material to create a secure seal.

Different products require different sealing parameters, such as temperature, pressure, and dwell time, to achieve an optimal seal.

Tray Handling and Automated Loading Systems

Tray handling and automated loading systems are designed to efficiently manage the packaging process, especially for high-volume operations. These systems can include tray formers, product loading mechanisms, and tray sealers.

Automation in tray handling and loading not only increases production speed but also reduces labor costs and minimizes the risk of contamination.

Integration with Industrial Robots and Cartoning Systems

The integration of MAP equipment with industrial robots and cartoning systems represents a significant advancement in packaging technology. Robots can be used for tasks such as product loading and case packing, enhancing efficiency and flexibility.

This integration allows for a seamless packaging process, from product preparation to final packaging, improving overall productivity.

Understanding these components and how they work together is key to optimizing MAP equipment performance and achieving the desired packaging outcomes.

- Gas mixing and delivery systems for precise gas blends

- Heat seal and sealing technology for secure packaging

- Tray handling and automated loading systems for efficient production

- Integration with industrial robots and cartoning systems for enhanced productivity

Modified Atmosphere Packaging Testing Equipment You Need

Ensuring the quality and integrity of Modified Atmosphere Packaging (MAP) requires specialized testing equipment. This equipment is crucial for verifying that the packaging meets the required standards for safety and freshness.

The right testing equipment helps in maintaining the high quality of packaged products by detecting any potential issues such as leaks, improper gas composition, or inadequate seal strength. This not only ensures compliance with regulatory requirements but also enhances customer satisfaction by delivering products that meet their expected freshness and safety standards.

Headspace Gas Analyzer for MAP Quality Control

A headspace gas analyzer is a critical tool for MAP quality control. It measures the composition of gases within the packaging, ensuring that the desired atmosphere is maintained. This is vital for products that are sensitive to oxygen, moisture, or other gases.

The analyzer helps in verifying that the gas mix is correctly proportioned and that there are no leaks or other issues that could compromise the packaging. Regular use of a headspace gas analyzer can significantly reduce the risk of product spoilage and improve overall quality control.

Vacuum Decay Leak Test for Packaging Integrity

The vacuum decay leak test is another essential method for ensuring packaging integrity. This test detects leaks in the packaging by measuring the rate of vacuum decay. It’s a non-destructive test that can be used on a variety of packaging formats.

By identifying leaks early, manufacturers can prevent product contamination and spoilage, thereby reducing waste and improving efficiency. The vacuum decay leak test is particularly useful for MAP applications where maintaining a specific atmosphere is critical.

Seal Strength Test ASTM F88 Standards

Seal strength testing is vital for ensuring that the packaging seals are strong enough to maintain the integrity of the package. The ASTM F88 standard provides a widely accepted method for testing seal strength.

This test involves measuring the force required to open a seal, providing valuable insights into the packaging’s ability to withstand handling and transportation stresses. Ensuring adequate seal strength is crucial for preventing package failure and maintaining product freshness.

CO2 Packaging Safety Monitoring Systems

CO2 packaging safety monitoring systems are designed to detect potential safety issues related to CO2 levels in MAP applications. High CO2 concentrations can be hazardous, and monitoring these levels is essential for maintaining a safe working environment.

These systems can be integrated into MAP lines to continuously monitor CO2 levels, alerting operators to any potential issues. This not only ensures a safer working environment but also helps in maintaining compliance with safety regulations.

| Testing Equipment | Purpose | Benefits |

|---|---|---|

| Headspace Gas Analyzer | Measures gas composition in packaging | Ensures correct gas mix, detects leaks |

| Vacuum Decay Leak Test | Detects leaks in packaging | Prevents contamination, reduces waste |

| Seal Strength Test (ASTM F88) | Measures seal strength | Ensures packaging integrity, prevents failure |

| CO2 Packaging Safety Monitoring | Monitors CO2 levels | Maintains safe working environment, ensures compliance |

Step 4: Evaluating Modified Atmosphere Packaging Machine Price and Options

When considering the purchase of a Modified Atmosphere Packaging (MAP) machine, understanding the price and available options is crucial. The cost of MAP machines varies widely based on factors such as production volume, level of automation, and specific features.

“The right MAP machine can significantly enhance your packaging operations, but it’s essential to evaluate the costs and benefits carefully,” says an industry expert. The investment in a MAP machine can be substantial, so it’s vital to assess the available options and their implications for your business.

Modified Atmosphere Packaging Machine Price Ranges in the USA

The price of MAP machines in the USA can range from a few thousand dollars for basic, manual-load systems to hundreds of thousands of dollars for high-speed, automated machines. For example, a manual-load MAP machine might cost between $5,000 and $20,000, while a high-speed, multi-station MAP machine could cost upwards of $200,000.

Manual-Load vs High-Speed Professional Packaging Systems

Manual-load MAP machines are suitable for small to medium-sized operations with lower production volumes. These machines require operators to load and unload products manually, which can be labor-intensive. In contrast, high-speed professional packaging systems are designed for large-scale operations and can significantly increase production efficiency.

Key differences between manual-load and high-speed MAP machines:

- Production volume capacity

- Level of automation

- Labor requirements

- Initial investment cost

Multi-Station MAP and CVP Machines for Large Operations

For large operations, multi-station MAP and CVP (Controlled Vacuum Packaging) machines offer advanced capabilities and higher production capacities. These machines can handle multiple packaging tasks simultaneously, improving efficiency and reducing labor costs.

As noted by a leading manufacturer, “Multi-station MAP machines are ideal for businesses with high-volume packaging needs, providing flexibility and scalability to meet demanding production requirements.”

MAP Applications by Food Category and Industry Segment

MAP technology is applied differently across the food industry spectrum, catering to the unique needs of various food categories and industry segments. This versatility is a key factor in its widespread adoption.

Fresh Produce and Vegetable Packaging

For fresh produce and vegetables, MAP plays a crucial role in maintaining freshness and extending shelf life. MAP tray sealers are particularly popular for packaging fresh produce, as they allow for the creation of a modified atmosphere around the product.

The right gas mix is essential for fresh produce. Typically, a mix with a lower oxygen level and a controlled amount of carbon dioxide and nitrogen is used to slow down the respiration rate of the produce, thereby keeping it fresh for longer.

Fresh Red Meat and Case-Ready Packaging Solutions

In the red meat industry, MAP is used to maintain the product’s appealing color and freshness. Case-ready packaging solutions, which involve packaging meat in a modified atmosphere, are gaining popularity due to their ability to extend shelf life and improve product appearance.

A specific gas mix is used for case-ready packaging, often involving a high oxygen level to maintain the meat’s red color, combined with carbon dioxide to inhibit bacterial growth.

Bakery Packaging and Baked Goods Preservation | Modified Atmosphere Packaging Machine (MAP)

Bakery products, such as bread and pastries, benefit from MAP by having their shelf life extended through the reduction of mold growth. Nitrogen flushing is commonly used in bakery packaging to remove oxygen and prevent staling.

Snacks and Dried Foods with Nitrogen Packaging | Modified Atmosphere Packaging Machine (MAP)

For snacks and dried foods, nitrogen packaging is a preferred method. By filling packages with nitrogen, manufacturers can prevent the ingress of oxygen and moisture, thereby preserving the product’s crispness and flavor.

| Food Category | Common MAP Gas Mix | Benefits |

|---|---|---|

| Fresh Produce | Low O2, controlled CO2 & N2 | Extended freshness, reduced respiration rate |

| Fresh Red Meat | High O2, CO2 | Maintains color, inhibits bacterial growth |

| Bakery Products | Nitrogen flushing | Reduces mold growth, prevents staling |

| Snacks & Dried Foods | Nitrogen | Preserves crispness, prevents moisture ingress |

Step 5: Sourcing Modified Atmosphere Packaging Machinery in the U.S.

When it comes to sourcing modified atmosphere packaging machinery in the U.S., several key factors must be considered to ensure the right equipment is selected. The process involves evaluating various manufacturers and their offerings to match the specific needs of your business.

Leading MAP Equipment Manufacturers in the United States

The U.S. market hosts a variety of MAP equipment manufacturers that cater to different industry needs. Companies like Ilapak, Pro Mach, and ULMA Packaging are among the leading providers of modified atmosphere packaging solutions. These manufacturers offer a range of machines, from basic models to highly sophisticated systems with advanced features.

When evaluating these manufacturers, it’s crucial to consider their reputation, the quality of their equipment, and their ability to provide customized solutions. Reliable manufacturers will have a proven track record, positive customer reviews, and a comprehensive portfolio of products.

Evaluating Packaging Equipment Suppliers and Support

Beyond the initial purchase, the level of support provided by packaging equipment suppliers is vital. This includes installation assistance, training for operators, and ongoing maintenance support. Suppliers who offer comprehensive support can significantly reduce downtime and improve overall efficiency.

It’s also important to assess the supplier’s ability to provide spare parts and consumables. A supplier with a robust inventory of parts can minimize delays in case of equipment failure, ensuring that production schedules are maintained.

Service, Parts Availability, and Maintenance Considerations

Maintenance considerations are a critical aspect of owning MAP machinery. The availability of service technicians, response times, and the cost of maintenance are all factors that can impact the total cost of ownership. Companies should look for suppliers that offer flexible maintenance plans and have a reputation for responsive service.

Additionally, the design of the machinery itself plays a significant role in maintenance. Equipment with easily accessible components and straightforward maintenance procedures can reduce labor costs and minimize downtime.

By carefully evaluating these factors, businesses can ensure that their MAP machinery continues to operate effectively, supporting their packaging needs over the long term.

Step 6: Installation and Integration of MAP Packaging Systems

The successful deployment of a Modified Atmosphere Packaging (MAP) system hinges on meticulous installation and integration planning. This step is crucial for ensuring that the MAP equipment operates efficiently and effectively within the existing production environment.

Facility Requirements and Gas Supply Utilities | Modified Atmosphere Packaging Machine (MAP)

Before installing a MAP system, it’s essential to assess the facility’s readiness to support the equipment. This includes evaluating the availability and quality of gas supply utilities. MAP machines require a consistent supply of high-purity gases, such as nitrogen, oxygen, and carbon dioxide, to maintain the desired atmosphere within the packaging.

The facility must also have adequate space for the MAP equipment, as well as sufficient electrical power and compressed air if required. Ensuring that the facility meets these requirements is vital for the smooth operation of the MAP system.

Integration with Existing Food Packaging Lines | Modified Atmosphere Packaging Machine (MAP)

Seamless integration with existing packaging lines is critical for minimizing disruptions to production. This involves assessing the compatibility of the MAP equipment with current machinery and workflows. Integration may require adjustments to the production line layout or the implementation of additional automation components to ensure that the MAP system operates in harmony with other equipment.

It’s also important to consider the throughput and production speed of the MAP system in relation to the existing packaging line. Ensuring that the MAP equipment can keep pace with production demands is essential for maintaining efficiency.

Staff Training and Safety Protocols for MAP Operations

Once the MAP system is installed and integrated, comprehensive training for operational staff is necessary. This training should cover the operation of the MAP equipment, routine maintenance tasks, and safety protocols. Proper training is key to preventing accidents and ensuring the consistent quality of packaged products.

Safety protocols should include procedures for handling gas cylinders, emergency shutdown procedures, and guidelines for personal protective equipment (PPE) usage. By prioritizing staff training and safety, businesses can minimize risks associated with MAP operations.

Step 7: Quality Control and Optimization of MAP Processes

To ensure the effectiveness of Modified Atmosphere Packaging (MAP), it’s crucial to implement a robust quality control process. Ongoing quality control and optimization are critical for maintaining the effectiveness of MAP, involving regular testing, monitoring, and troubleshooting.

Effective MAP quality control involves several key components, including establishing testing and monitoring protocols, monitoring gas composition and package integrity, and troubleshooting common equipment issues.

Establishing Testing and Monitoring Protocols | Modified Atmosphere Packaging Machine (MAP)

Establishing comprehensive testing protocols is vital for ensuring the quality and safety of MAP products. This includes using modified atmosphere packaging testing equipment such as headspace gas analyzers to verify the gas composition within packages.

Regular monitoring helps in early detection of potential issues, such as leaks or incorrect gas mixtures, allowing for prompt corrective actions.

Monitoring Gas Composition and Package Integrity

Gas composition monitoring is essential to ensure that the desired atmosphere is maintained within the package. This involves checking the levels of gases such as oxygen, nitrogen, and carbon dioxide.

Ensuring package integrity is also critical, as any compromise in the packaging can lead to spoilage or contamination. Techniques such as vacuum decay leak testing are used to verify the integrity of the packaging.

Troubleshooting Common MAP Equipment Issues | Modified Atmosphere Packaging Machine (MAP)

Despite the best maintenance practices, MAP equipment issues can arise. Common problems include issues with gas flushing, sealing, and packaging material handling.

Effective troubleshooting involves identifying the root cause of the problem and implementing corrective actions. This may involve adjusting equipment settings, replacing worn-out parts, or modifying packaging materials.

By implementing these quality control measures, businesses can optimize their MAP processes, reduce waste, and improve product shelf life.

Calculating ROI for Modified Atmosphere Packaging Equipment Investment

Investing in a Modified Atmosphere Packaging (MAP) machine is a strategic decision that can significantly impact your business’s bottom line. To ensure that this investment yields the expected returns, it’s crucial to calculate the Return on Investment (ROI) accurately.

The ROI calculation for MAP equipment involves considering various factors, including the initial investment cost, operational savings, and revenue enhancements. By understanding these elements, businesses can make informed decisions about adopting MAP technology.

Shelf Life Extension and Food Waste Reduction Benefits

One of the primary benefits of MAP is the extension of shelf life for perishable products. By modifying the atmosphere around the product, MAP technology slows down the deterioration process, thereby reducing food waste. According to a study,

“The use of MAP can extend the shelf life of products by up to 300%, significantly reducing waste and improving product availability.”

The Journal of Food Science

This extension in shelf life not only reduces waste but also improves product availability, leading to increased customer satisfaction and loyalty.

| Product Category | Average Shelf Life Extension | Estimated Waste Reduction |

|---|---|---|

| Fresh Produce | 200% | 30% |

| Meat and Poultry | 150% | 25% |

| Bakery Products | 250% | 40% |

Labor Savings and Throughput Improvements | Modified Atmosphere Packaging Machine (MAP)

MAP equipment can also lead to significant labor savings and throughput improvements. Automated MAP systems reduce the need for manual labor in packaging operations, thereby decreasing labor costs. Moreover, high-speed MAP machines can increase production throughput, enabling businesses to meet growing demand more efficiently.

Labor savings can be achieved through automation, while throughput improvements can be realized through the high-speed capabilities of modern MAP equipment.

Market Expansion and Premium Pricing Opportunities | Modified Atmosphere Packaging Machine (MAP)

By improving product shelf life and quality, businesses can expand their market reach and command premium prices for their products. MAP technology enables companies to supply products to distant markets without compromising on quality, thereby opening up new revenue streams.

Premium pricing opportunities arise from the ability to offer fresher products with longer shelf lives, appealing to consumers willing to pay more for quality.

Payback Period Analysis and Financial Modeling

To accurately calculate the ROI, businesses must conduct a thorough payback period analysis and financial modeling. This involves estimating the initial investment, ongoing costs, and expected revenue increases. By using financial models, companies can predict the payback period for their MAP equipment investment.

A detailed financial analysis will help businesses understand the viability of their MAP investment and make informed decisions about their packaging operations.

At The End of: Modified Atmosphere Packaging Machine (MAP)

Modified atmosphere packaging (MAP) has emerged as a vital technology in the food packaging industry, offering numerous benefits for businesses and consumers alike. By understanding the principles of MAP, including gas mixes, film specifications, and equipment options, companies can make informed decisions to enhance their packaging operations.

The use of MAP extends the shelf life of food products, preserves their quality, and reduces food waste. With various types of MAP machines available, businesses can choose the most suitable equipment for their specific needs. By implementing MAP, companies can improve their bottom line through labor savings, increased throughput, and market expansion opportunities.

As the demand for fresh and high-quality food products continues to grow, the importance of MAP will only continue to increase. By leveraging this powerful packaging technology, businesses can stay ahead of the competition and meet the evolving needs of consumers.

FAQ

A modified atmosphere packaging machine raises a few recurring questions in U.S. operations, especially around whether MAP changes regulatory expectations and how to explain the process to buyers. These short answers keep the focus at a high level so you can decide what to validate or document next. 21 CFR Part 112 (Produce Safety Rule) scope and definitions

What is the primary function of a modified atmosphere packaging machine (MAP)?

A modified atmosphere packaging machine is designed to replace the atmospheric air inside a package with a specific protective gas mix—typically nitrogen, CO2, or a blend of both. This process, facilitated by food packaging machinery, significantly slows down the deterioration of perishable goods by inhibiting aerobic spoilage and oxidation, effectively extending the shelf-life of products like sandwich packaging, chilled food-to-go, and bakery packaging.

How does equilibrium modified atmosphere packaging (emap) differ from standard MAP?

While standard modified atmosphere packaging (map) creates a fixed gas environment, equilibrium modified atmosphere packaging (emap) is specifically used for fresh produce packaging solutions. It utilizes micro-perforated oxygen transmission rate (otr) film for map to balance the respiration rate of the produce with the gas exchange through the film. This packaging technology ensures that oxygen and CO2 levels remain at an optimal level to prevent anaerobic spoilage in fresh produce and vegetables.

What are the 2 main gas flushing systems used in high-speed professional packaging systems?

The 2 main gas flushing systems are gas flushing and compensated vacuum. In gas flushing packaging systems, a continuous stream of inert gas displaces the air before the package is sealed, often seen in map flow wrapping equipment. The compensated vacuum method, common in vacuum chamber machines and thermoforming machines, first pulls a vacuum to remove all air and then injects the case-ready packaging gas mix for higher precision.

Why is EVOH barrier film for food packaging essential for maintaining gas composition?

EVOH barrier film for food packaging provides an exceptional gas barrier that prevents the modified atmosphere from leaking out and external oxygen from seeping in. When combined with moisture vapor transmission rate (mvtr) packaging specs, it ensures that the modified atmosphere packaging equipment‘s efforts to preserve the product are not wasted, which is critical for modified atmosphere packaging (map) for fresh red meat.

What should I expect regarding the modified atmosphere packaging machine price in the USA?

The modified atmosphere packaging machine price varies significantly based on automation levels. A manual-loadmap tray sealer for produce may start at a lower price point, whereas high-speed, multi-station map/cvp systems or map vertical form fill & seal equipment designed for industrial-scale operations require a larger capital investment. Professional packaging equipment suppliers like CV-Tek provide tailored quotes based on throughput and integration needs.

Which modified atmosphere packaging testing equipment is required for quality control?

To ensure food preservation, operators must use a headspace gas analyzer for map to verify the internal gas concentration. Additionally, a vacuum decay leak test for packaging is vital for identifying microscopic leaks, while a seal strength test astm f88 ensures the physical integrity of the heat seal & machinery performance. Larger plants also implement CO2 packaging safety monitoring to protect employees from gas leaks.

Can industrial robots be integrated into a map packaging system?

Yes, modern modified atmosphere packaging machinery is often integrated with industrial robots for tray handling, loading, and cartoning systems. Companies like CV-Tek, known as the leader in modified atmosphere packaging machines, design their map packaging machines to work seamlessly with automation to increase efficiency and reduce food packaging technology labor costs.

What are the benefits of nitrogen flushing for food packaging in the snacks industry?

Nitrogen flushing for food packaging is the standard for modified atmosphere packaging (map) for snacks and dried foods. Since nitrogen is an inert gas, it displaces oxygen to prevent rancidity of fats and oils. It also provides a “pillow” effect inside the gas flushing packaging machine, protecting delicate products from crushing during transport, which is essential for party packaging and bakery packaging.

How do I find a reliable modified atmosphere packaging machine manufacturer in the U.S.?

When looking for a modified atmosphere packaging machine in the u.s., it is crucial to evaluate the manufacturer’s track record in freshness preservation equipment. CV-Tek is a prominent machine manufacturer known for modified atmosphere packaging equipment manufactured by proud, dedicated employees. Ensure your packaging equipment supplier offers robust service, parts availability, and maintenance for modified atmosphere packing machines.

How does a gas flushing machine extend the shelf life of fresh red meat?

In modified atmosphere packaging (map) for fresh red meat, a specific high-oxygen case-ready packaging gas mix (usually 80% O2 and 20% CO2) is used. The oxygen maintains the bright red “bloom” of the meat, while the CO2 acts as an antimicrobial agent. This food preservation technology, executed by map tray packaging equipment or thermoforming machines, can extend the shelf life of red meat from a few days to over two weeks.

What role does ultrasonic cake cutting play in a MAP production line?

Ultrasonic cake cutting is often integrated into bakery packaging lines before the map machine packaging phase. It ensures clean, precise cuts without sticking, which is vital for maintaining the aesthetic quality of chilled food-to-go. Once cut, the product enters map flow wrapping equipment or a map vertical form fill & seal equipment to be preserved in an inert atmosphere.

What are the financial considerations when calculating ROI for map packaging equipment?

Calculating the ROI for a modified atmosphere packaging map machine involves looking at shelf life extension, which reduces food waste and allows for wider distribution. Additionally, high-speedmodified atmosphere packaging map equipment reduces labor costs through automation. By utilizing vacuum packaging equipment with gas flushing, processors can often command premium pricing for “fresh, never frozen” products in the food industry machinery market.

Does MAP replace refrigeration?

No—MAP slows quality loss, but temperature control remains the primary safety and shelf-life driver.

Can I use one gas mix for everything?

Usually not—fat content, respiration, and moisture change what “works,” so mixes often differ by category and even by SKU.

What’s the easiest way to start small?

Many operations begin with a tray sealer, cylinders, a simple mixer, and a basic verification routine before upgrading to bulk and inline monitoring.

What fails most often in real operations?

Seal issues, film mismatch, and cold-chain gaps are the top causes of disappointing MAP results.

How do I explain MAP to retail buyers?

Frame it as controlled headspace gases + verified seals + validated shelf life, supported by consistent cold storage and clear labeling.

Conclusion of: Modified Atmosphere Packaging Machine (MAP)

Why MAP is showing up on U.S. farms and small processors

A modified atmosphere packaging machine is often the difference between “sell it today” and “sell it all week” for local meat, produce, and value-added products, because it lets you manage headspace gases while still using familiar retail formats like trays, pouches, and clamshells. In the U.S., that matters when you’re trying to reduce shrink, keep quality consistent during transport, and meet buyer expectations for appearance and shelf life without relying on heavy preservatives. The right setup can also help smaller operations compete with larger “case-ready” supply chains by standardizing package quality across batches and seasons. FSIS overview of meat and poultry packaging

What MAP is (and what it is not)

A modified atmosphere packaging machine works by replacing normal air in the package with a controlled gas mix—typically some combination of carbon dioxide, nitrogen, and sometimes oxygen—then sealing the package so product quality changes more slowly. It is not a substitute for refrigeration, sanitation, or validated process controls; it’s a tool that changes the package environment so oxidation, microbial growth, and moisture-related quality losses can be managed more predictably. The most important practical idea is that MAP is a system: product, temperature, gas mix, and film must match each other, or shelf life gains can disappear fast. Peer-reviewed overview of MAP principles and performance

Food safety first: reduced-oxygen packaging is a control strategy, not a shortcut

A modified atmosphere packaging machine can create reduced-oxygen conditions that slow spoilage, but those same conditions can raise food safety stakes if time and temperature controls fail or if the product supports toxin formation under anaerobic conditions. That’s why MAP programs typically require disciplined cold-chain management, clear shelf-life limits, and written controls (often HACCP-style) tied to your product category. If you pack seafood, prepared foods, or other higher-risk items, you must treat MAP as part of a validated hazard-control plan rather than a marketing feature. FDA Seafood HACCP hazards guidance for reduced-oxygen packaging

Common MAP machine formats and where each fits

A modified atmosphere packaging machine usually shows up in one of three formats: a tray sealer (great for retail-ready trays and moderate volumes), a thermoformer (best for higher throughput and lower film cost per pack), or a chamber-based gas-flush system (often used for smaller runs, specialty items, or mixed SKUs). Tray sealers are popular with farm stores and small co-packers because changeovers can be quick and the package looks “retail standard.” Thermoformers shine when you need steady speed, consistent pack geometry, and automation options like inline checkweighing and seal inspection.

Gas supply and mixing: the part that quietly decides your results

A modified atmosphere packaging machine is only as consistent as the gas supply and mixing method feeding it, because drift in oxygen or carbon dioxide can change color, drip loss, texture, and microbial behavior from lot to lot. Smaller operations often start with cylinders and a simple mixer, while larger plants use bulk tanks, blending panels, and in-line analyzers to keep recipes stable across shifts. In practice, the “best” system is the one your team can verify every day with documented checks—especially for oxygen levels and seal integrity.

Gas roles in plain English: why CO2, N2, and O2 behave differently

A modified atmosphere packaging machine typically uses carbon dioxide to suppress many spoilage organisms, nitrogen as an inert “filler” gas to prevent package collapse, and oxygen when color or respiration needs demand it. CO2 is effective but soluble, which can pull it out of the headspace and cause the pack to sink unless your film and gas ratio are designed for it. Oxygen can protect red-meat color but may accelerate oxidation in fatty foods, so it must be chosen intentionally rather than copied from a competitor’s label.

Red meat: when oxygen helps color, and when it hurts quality

A modified atmosphere packaging machine for beef often balances consumer color expectations against oxidation risk, because high-oxygen mixes can keep a bright red look but may speed rancidity or discoloration later in shelf life. Some programs use low levels of carbon monoxide to stabilize color in certain applications, which makes regulatory awareness, labeling discipline, and buyer requirements critical before you commit. If you sell into wholesale or retail channels, align your gas strategy with downstream display time, lighting, and temperature realities—those conditions can overwhelm “lab-perfect” mixes quickly.

Poultry and further-processed proteins: focus on drip, odor, and cold-chain discipline

A modified atmosphere packaging machine for poultry is often tuned to manage purge and odor while supporting safe, stable refrigerated storage, which makes consistent temperature control and film choice especially important. Poultry products can show big quality swings when CO2 is too low (faster spoilage) or too high (texture changes and package collapse), so operators typically rely on documented mix targets and frequent headspace checks. If you pack marinated or seasoned items, remember that ingredients can change gas absorption and microbial behavior, so your “base mix” may need adjustment by SKU.

Fresh produce: respiration makes “the right mix” a moving target

A modified atmosphere packaging machine for produce must account for respiration, because the product itself consumes oxygen and produces carbon dioxide over time, meaning the headspace composition changes after sealing. That’s why many produce programs rely on equilibrium MAP (EMAP), where film permeability and package size are chosen so the product “self-balances” into a safe, quality-preserving range during storage. The practical takeaway is that produce MAP is less about copying a gas recipe and more about matching film OTR/CO2TR to the commodity, temperature, and pack weight you actually run. UC Davis postharvest guidance on MAP for fresh produce

Dairy, cheese, and high-moisture foods: manage mold risk without crushing texture

A modified atmosphere packaging machine is widely used for fresh and soft cheeses because CO2 can slow microbial growth while nitrogen helps maintain pack shape and reduces oxygen-driven quality changes. The catch is that cheese composition, salt, moisture, and surface conditions can shift results, so shelf-life validation matters more than guessing based on another product style. For farmstead and small-batch brands, the biggest wins often come from repeatable sealing, consistent cold storage, and films that prevent oxygen ingress during longer regional distribution. Open-access research on MAP effects in cheese systems

Film specs that actually matter: OTR, CO2TR, and MVTR

A modified atmosphere packaging machine can only hold a gas mix if the film is designed to resist the right kind of transmission, which is why oxygen transmission rate (OTR), carbon dioxide transmission behavior, and moisture vapor transmission rate (MVTR) belong on your buying checklist. In real-world terms, low OTR helps preserve oxygen-sensitive foods, while MVTR influences condensation, label scuffing, and drip-related appearance issues. When you compare films, always check the stated test conditions (temperature and humidity), because “great numbers” at one condition may not match your cold-room reality. Michigan State packaging resource on film testing and properties

OTR testing and why “one number” can mislead you

A modified atmosphere packaging machine program should treat OTR as a decision input, not a single magic threshold, because barrier needs differ by product fat content, expected display time, and whether you use oxygen in the headspace. Some films look similar on a datasheet but behave differently once seals, folds, and thermoformed corners are added to the geometry. If you’re comparing suppliers, ask for consistent test methods and conditions, then validate with your actual package shape and storage temperature.

Thermoforming changes barrier performance: plan for it, don’t discover it

A modified atmosphere packaging machine that thermoforms trays from rollstock can alter barrier layers during forming, which may reduce performance in corners, radii, and high-stretch zones even when the “flat film” datasheet looks perfect. This is why high-speed systems often rely on robust multilayer structures and careful forming controls to protect EVOH and other barrier components. If you’re scaling volume, include forming effects in your validation plan so shelf-life performance stays stable when you increase line speed or change tray depth.

Moisture control: MVTR, fogging, and why your packs look “wet” on the shelf

A modified atmosphere packaging machine can create great gas results and still lose retail appeal if moisture management is ignored, because condensation and drip can make products look old even when they’re safe. MVTR helps predict how moisture migrates through the film, but you also need to consider headspace humidity, anti-fog coatings, and the temperature swings your packs see during loading and transport. For many operations, improving moisture appearance is less about “stronger gas” and more about choosing the right lid film and managing cold-chain transitions. ASTM standard for measuring water vapor transmission rate (MVTR)

Seals are the real barrier: sealant layers, jaw settings, and peelability

A modified atmosphere packaging machine can only deliver shelf-life gains if your seals are strong, continuous, and repeatable, because a tiny channel leak can erase your gas mix in hours. Practical seal success comes from matching the sealant layer to the tray material, controlling seal temperature and dwell time, and keeping sealing surfaces clean and undamaged. If your market expects easy-open packs, peelable seals can work well, but they must still meet leak and strength targets under real handling conditions.

Seal integrity testing: don’t wait for complaints to learn you have leaks

A modified atmosphere packaging machine line should have a clear leak-testing strategy that matches your risk and volume, because “looks sealed” is not a verification method. Vacuum decay and other nondestructive tests are common for validating process stability and catching drift in sealing performance before it reaches customers. Many U.S. operators combine periodic destructive checks (for strength and visual channels) with routine nondestructive screening so they can document control without wasting excessive finished product.

Simple gross-leak checks still matter (especially for startups)

A modified atmosphere packaging machine operation doesn’t always need complex instrumentation on day one, but it does need consistent, documented checks that catch obvious failures early. Bubble emission testing and similar methods can be useful for diagnosing setup issues, worn sealing surfaces, poor tray-lid compatibility, or contamination in the seal area. The key is to standardize how you test, how often you test, and what you do when results fail, so the method becomes part of your control plan rather than an occasional troubleshooting trick.

Validation and shelf life: prove your claim with your product and your cold chain

A modified atmosphere packaging machine should be validated with your actual SKU, because microbial behavior depends on product composition, starting load, temperature history, and the final headspace your line consistently achieves. A practical validation package includes target gas specs, acceptable oxygen limits over time, seal-integrity criteria, and shelf-life endpoints that reflect how your buyers actually store and display the product. When you do this well, MAP becomes predictable and repeatable instead of a cycle of “it worked last week” surprises.

Sanitation and preventive controls: MAP adds equipment surfaces and steps to manage

A modified atmosphere packaging machine introduces additional food-contact surfaces, change parts, and cleaning challenges, so your sanitation program must be written, trained, and verified like any other critical equipment program. In U.S. regulated environments, that usually means documented procedures, validated cleaning chemicals and concentrations, allergen controls when relevant, and records that show consistent execution. Hygienic design, easy-to-clean guarding, and disciplined teardown schedules often deliver more real-world shelf-life stability than chasing “perfect” gas numbers. 21 CFR Part 117 (CGMP and preventive controls framework)

Fresh-cut and mixed-type facilities: packaging decisions can change your compliance needs

A modified atmosphere packaging machine used for fresh-cut produce or value-added packs can move an operation into requirements beyond simple farm handling, especially when cutting, mixing, and packaging are part of the workflow. In practice, you need clear SOPs for wash water management, cross-contamination prevention, cold holding, and shelf-life controls that match your distribution window. If you’re selling to schools, retailers, or meal-kit channels, buyers may also require written food safety plans and third-party audits that scrutinize packaging controls closely. FDA fresh-cut produce guidance (U.S. context)

Labeling and date marks: don’t let a great pack fail at the label

A modified atmosphere packaging machine can deliver strong quality, but labeling errors still create costly rework, buyer rejections, or enforcement risk, especially when date marks and storage instructions are unclear. For meat and poultry under FSIS jurisdiction, date labeling is generally voluntary but must be truthful and not misleading, and many buyers have strict expectations for “use-by” or “sell-by” practices. Align your label language with your validated shelf life and your cold-chain assumptions so the pack communicates what your process can actually support. FSIS guidance on food product dating

Worker safety around gases: CO2 and nitrogen require the same seriousness as chemicals

A modified atmosphere packaging machine that uses CO2 or nitrogen can create serious hazards if gases accumulate in poorly ventilated rooms, confined spaces, or around bulk systems, so safety controls should be built into your layout and training from the start. Practical steps include ventilation checks, gas detection where needed, clear cylinder and bulk tank procedures, and emergency response planning that the whole team actually practices. If you are adding cryogenic or bulk systems as you scale, treat the upgrade as an EHS project, not just an equipment purchase. OSHA hazard alert on nitrogen and CO2 release risks

Quick checklist

A modified atmosphere packaging machine purchase is easier when you score options against a short, practical checklist that forces you to match equipment choices to your product risk, throughput needs, and verification ability. Use this list to compare vendors and prevent “feature shopping” that doesn’t help your real operation. FDA overview of preventive controls expectations

- Define your top 3 SKUs (pack format, target shelf life, weekly volume, seasonal swings).

- Set headspace targets (gas recipe and oxygen limit) and how you will verify them.

- Choose machine format (tray sealer vs thermoformer vs chamber) based on changeover and speed needs.

- Confirm gas supply plan (cylinders vs bulk, redundancy, regulator quality, and service support).

- Specify film and tray requirements (OTR/MVTR targets, anti-fog needs, sealant compatibility).

- Require seal verification (strength checks + leak test method + failure response steps).

- Plan sanitation (tool-less change parts where possible, written teardown schedule, training).

- Document temperature controls from pack-out to delivery (who owns each step).

- Confirm label requirements (date marks, storage statements, buyer specifications).

- Estimate true operating costs (gas, film, labor, maintenance parts, downtime).

Common mistakes to avoid

A modified atmosphere packaging machine can underperform for reasons that have nothing to do with the vendor, because most failures come from weak verification, mismatched films, or poor cold-chain discipline rather than the sealing head itself. Avoiding common mistakes is largely about setting measurable targets, checking them routinely, and responding fast when drift appears. FDA import-alert context on reduced-oxygen packaging risk controls

- Copying a competitor’s gas mix: Start with product behavior and temperature reality, then validate with your SKU.

- Ignoring film test conditions: Confirm OTR/MVTR values at conditions close to your storage temperature and humidity.

- Assuming seals are fine because they “look” fine: Add routine strength and leak checks with documented limits.

- Letting changeovers become uncontrolled experiments: Lock in setup recipes (temperature, dwell, pressure) per SKU.

- Overfilling headspace: Too little headspace can destabilize gas ratios and increase drip/contact issues.

- Underestimating CO2 absorption: Plan for pack collapse risk and correct it with mix ratios and structural choices.

- Skipping shelf-life validation: Use defined endpoints (sensory + microbiological targets) tied to your distribution window.

- Weak cold-chain discipline: MAP cannot rescue product held warm during staging or delivery delays.

- Not training for gas safety: Add ventilation and monitoring plans as part of your standard operating culture.

Costs and ROI snapshot

A modified atmosphere packaging machine investment typically includes the equipment itself plus the “system costs” that determine daily performance: gas supply hardware, film/tray specs, headspace verification tools, sanitation labor, and maintenance parts. In the U.S., financing options and eligibility can differ by whether you are a rural business, a cooperative, or a farm doing value-added processing, so you should map the project structure before you shop lenders. The most realistic budgeting approach is to price a base configuration, then add costs for automation, validation tools, and facility upgrades you will almost certainly need within 6–18 months. USDA Rural Development B&I guaranteed loan program overview

A modified atmosphere packaging machine ROI case is usually driven by fewer spoilage write-offs, more sellable days on the shelf, and smoother distribution—especially when you serve retailers who penalize short-coded product. A practical way to estimate ROI is to measure current weekly shrink dollars, estimate a conservative percentage reduction based on pilot runs, and compare that to your monthly operating costs (film, gas, labor, downtime) plus financing. Because U.S. policy goals are increasingly focused on reducing food waste, many buyers also respond positively to documented waste reductions tied to packaging improvements. EPA information on the U.S. 2030 food loss and waste reduction goal

A modified atmosphere packaging machine project can sometimes be paired with grants or programs that support value-added processing, market expansion, or rural business development, but these often require planning documents, matching funds, and clear scope definitions. Even if you don’t pursue funding, building the same level of documentation—feasibility, market plan, food safety controls, and a realistic operating budget—makes vendor comparisons sharper and reduces expensive mid-project surprises. If you are scaling from farmstand to wholesale, treat MAP as a business system upgrade, not a single piece of equipment, and your ROI math will be more accurate. USDA Rural Development Value-Added Producer Grants overview

Final thought

A modified atmosphere packaging machine is at its best when you treat it as an integrated system—product behavior, gas mix, film properties, seal verification, sanitation, and cold chain all working together—because that approach produces repeatable shelf-life gains instead of occasional wins. When you validate your settings and document your controls, MAP becomes a dependable tool for selling more of what you produce, with less waste and fewer “surprise” quality complaints. USDA overview of the national strategy on food loss and waste

Sources & References

- IFT overview article on modified atmosphere packaging

- FDA Food Labeling Guide (PDF)

- FDA guidance page for the Food Labeling Guide

- FDA Food Code (PDF) with reduced-oxygen packaging references

- University of Maine Extension bulletin on reduced-oxygen packaging

- Compressed Gas Association information on carbon dioxide safety

- NIOSH IDLH documentation for carbon dioxide

- FDA FSMA Produce Safety Rule overview

- USDA U.S. Food Loss and Waste 2030 Champions

- FDA Import Alert detail page (reduced oxygen packaging context)

- FDA compliance program document on general food labeling requirements (PDF)

- Springer reference book page on modified atmosphere packaging

- Wiley/IFT Press reference entry on modified atmosphere packaging

- ScienceDirect topic page on modified atmosphere packaging (background)