The food distribution plays a vital role in the U.S. food industry economy, connecting producers and manufacturers with consumer-facing businesses like restaurants and stores. Wholesale food distribution is a complex process that involves various stakeholders, from broadline distributors to specialty food distributors.

Foodservice distribution is a critical component of this industry, ensuring that the right products reach the right businesses at the right time. With numerous options available, choosing the right food distributor can be a daunting task.

Understanding how wholesale distribution works and selecting a reliable distributor are crucial for businesses to succeed. This article will provide an overview of the food distribution landscape and offer guidance on how to choose a distributor that meets your business needs.

Key Takeaways

- Understanding the role of food distributors in the U.S. economy

- The different types of food distributors, including broadline and specialty distributors

- The importance of choosing the right food distributor for your business

- Key factors to consider when selecting a food distributor

- The benefits of effective wholesale food distribution

Understanding the Food Distribution Landscape in the U.S.

The food distribution network in the U.S. plays a vital role in connecting producers with consumers. It is a complex system that involves various stakeholders, including manufacturers, distributors, and retailers. At its core, food distribution is about ensuring that products move efficiently from the point of production to the point of consumption.

The Role of Food Distributors in the Supply Chain

Food distributors act as intermediaries between food producers and consumers. They buy products in bulk from manufacturers, store them in warehouses, and then deliver these products to foodservice operators, retailers, and other customers. This role is crucial as it allows manufacturers to focus on production while leaving the logistics to the distributors.

Key functions of food distributors include:

- Procurement of products from manufacturers

- Warehousing and inventory management

- Order fulfillment and delivery

- Providing value-added services such as product tracking and inventory management

Economic Impact of Food Distribution in America

The economic impact of food distribution in the U.S. is significant. Food distribution companies contribute to the economy by creating jobs, both directly and indirectly, and by facilitating the flow of goods across the country.

“The food distribution industry is a critical component of the U.S. economy, supporting thousands of jobs and generating billions of dollars in revenue each year.”

A detailed breakdown of the economic impact can be seen in the following table:

| Industry Segment | Employment (in thousands) | Revenue (in billion USD) |

|---|---|---|

| Food Distribution | 450 | 250 |

| Food Manufacturing | 520 | 750 |

| Food Retail | 3,500 | 800 |

The table illustrates the significant role that food distribution plays in the broader food industry, both in terms of employment and revenue generation.

Types of Food Distributors in the American Market

Understanding the different types of food distributors is crucial for businesses looking to navigate the complex U.S. food supply chain. The American food distribution landscape is characterized by a variety of business models, each catering to specific customer needs and product categories.

Broadline Distributors: The One-Stop Shop

Broadline distributors offer a wide range of products, making them a one-stop shop for many foodservice operators. They typically carry a broad portfolio of products, including dry goods, fresh produce, meats, and dairy products. This comprehensive offering allows customers to consolidate their purchasing, simplifying their supply chain management.

Key characteristics of broadline distributors include:

- Wide product range

- Multiple delivery options

- Advanced logistics capabilities

- Strong customer service

Specialty Food Distributors: Niche and Gourmet Products

Specialty food distributors focus on specific product categories or niche markets, often carrying gourmet, artisanal, or hard-to-find items. These distributors cater to businesses looking for unique products to differentiate their offerings.

Specialty distributors often serve:

- High-end restaurants

- Specialty food stores

- Artisanal producers

Regional vs. National Distribution Networks

Food distributors can be categorized based on their geographic coverage. Regional distributors operate within specific geographic areas, often providing tailored services and localized inventory management. National distributors, on the other hand, offer broader coverage, serving customers across multiple regions or the entire country.

| Distribution Type | Regional | National |

|---|---|---|

| Geographic Coverage | Specific regions or states | Multiple regions or nationwide |

| Service Characteristics | Localized service, tailored to regional needs | Standardized service across regions |

| Product Offering | May include regional specialties | Generally consistent product range nationwide |

How Wholesale Food Distribution Works

The journey of food products from manufacturers to consumers is facilitated by wholesale food distributors. These distributors play a crucial role in ensuring that food products are delivered efficiently and effectively across the supply chain.

From Manufacturer to End Consumer: The Distribution Chain

The distribution chain in wholesale food distribution is complex, involving multiple stakeholders and logistical considerations. It begins with manufacturers producing food products, which are then transported to warehouses or distribution centers. These facilities serve as critical hubs where products are stored, managed, and dispatched to various customers, including retailers, restaurants, and other foodservice providers.

The distribution chain is not just about moving products from one place to another; it’s also about ensuring that products are handled and stored properly to maintain their quality and safety. This involves careful planning and coordination among manufacturers, distributors, and customers.

Warehouse Operations and Logistics

Warehouse operations are a critical component of wholesale food distribution. Distributors manage large warehouses where they store a wide range of food products. Effective warehouse management involves organizing storage to maximize space, implementing efficient inventory management systems, and ensuring that products are easily accessible for order fulfillment.

Logistics play a vital role in the distribution process, involving the transportation of products from manufacturers to warehouses and then to customers. Distributors use various transportation modes, including trucks, refrigerated vehicles for perishable goods, and sometimes rail or air transport for longer distances or specific types of cargo.

Order Fulfillment Processes

Order fulfillment is the final stage in the wholesale food distribution process. It involves receiving orders from customers, processing these orders, and delivering the products as required. Efficient order fulfillment requires accurate inventory management, reliable logistics, and a robust system for tracking orders and managing customer communications.

To enhance order fulfillment, many distributors invest in technology, such as inventory management software and automated order processing systems. These tools help reduce errors, improve delivery times, and increase customer satisfaction.

In conclusion, wholesale food distribution is a multifaceted process that relies on a well-coordinated distribution chain, efficient warehouse operations, and effective order fulfillment. By understanding these elements, businesses in the food industry can better navigate the complexities of food distribution and ensure that products are delivered to consumers safely and efficiently.

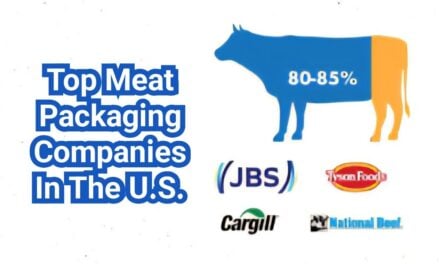

Major Food Distributors in the U.S. Market

The U.S. food distribution market is dominated by a few large players. These major food distributors play a crucial role in supplying foodservice providers across the country.

Industry Giants: Sysco, US Foods, and Performance Food Group

The food distribution landscape in the U.S. is led by three industry giants: Sysco, US Foods, and Performance Food Group. These companies are among the largest foodservice distributors in the country, offering a wide range of products to various customers.

Sysco is the largest food distribution company in the U.S., serving a broad customer base that includes restaurants, healthcare facilities, and educational institutions. US Foods is another major player, offering a diverse portfolio of products, including fresh produce, meat, and dry goods.

| Company | Revenue (2022) | Customer Base |

|---|---|---|

| Sysco | $76.3 billion | Restaurants, healthcare, education |

| US Foods | $29.7 billion | Restaurants, healthcare, hospitality |

| Performance Food Group | $15.4 billion | Restaurants, healthcare, education |

Regional Powerhouses: Gordon Food Service, Reinhart, and Ben E. Keith

While the industry giants dominate the national landscape, regional distributors play a significant role in their respective markets. Companies like Gordon Food Service, Reinhart, and Ben E. Keith are well-established regional powerhouses.

Gordon Food Service, for example, is a leading distributor in the Midwest, offering a range of products and services tailored to the local market. Reinhart FoodService is another significant regional player, serving customers in the Midwest and beyond.

Specialty and Ethnic Food Distributors

In addition to broadline distributors, specialty and ethnic food distributors cater to specific market niches. These distributors provide unique products that are not typically found in larger distributors’ portfolios.

Specialty distributors focus on particular cuisines or dietary preferences, such as organic or gourmet products. Ethnic distributors, on the other hand, specialize in products catering to specific ethnic or cultural groups.

The Business Model of Food Distribution Companies

The business model of food distributors is multifaceted, involving various revenue streams and services that enhance their distribution capabilities. Food distribution companies operate as intermediaries between manufacturers and foodservice operators, retailers, and other customers, providing a vital link in the supply chain.

Revenue Streams and Profit Margins

Food distribution companies generate revenue primarily through the sale of food products to their customers. The profit margins in this industry are typically slim, often ranging between 2-5%, due to intense competition and the low-margin nature of the food products themselves. To maintain profitability, food distributors must focus on efficient logistics, inventory management, and sales volume.

Key revenue streams for food distribution companies include:

- Sale of food products

- Delivery and logistics services

- Value-added services such as menu planning and inventory management

- Private label products

Value-Added Services Beyond Distribution

Beyond their core distribution services, many food distribution companies offer value-added services to differentiate themselves and provide additional value to their customers. These services can include menu planning and development, inventory management solutions, and marketing support.

For instance, some distributors offer business intelligence tools that help customers analyze their sales data and optimize their purchasing decisions. Others may provide training and support for new menu items or culinary techniques, enhancing the customer’s ability to compete in the market.

By offering these value-added services, food distribution companies can strengthen their relationships with customers, increase customer loyalty, and potentially increase their revenue through higher-margin service fees.

Foodservice Distribution vs. Retail Distribution

Understanding the differences between foodservice and retail distribution is crucial for businesses looking to navigate the complex food supply chain. While both channels are vital to the food industry, they serve distinct markets and have different operational requirements.

Key Differences in Service Models

Foodservice distribution is tailored to the needs of restaurants, cafes, and other foodservice businesses. It involves delivering products in bulk or in specific quantities that meet the operational demands of these establishments. In contrast, retail distribution focuses on supplying products to consumers through grocery stores, supermarkets, and other retail outlets.

The service models for foodservice and retail distribution differ significantly. Foodservice distributors often provide additional services such as menu planning, inventory management, and culinary support to their customers. Retail distributors, on the other hand, focus on efficiently stocking shelves and managing inventory levels to meet consumer demand.

Product Packaging and Presentation Requirements

Product packaging is another area where foodservice and retail distribution diverge. Foodservice products are typically packaged in larger quantities or in formats that are convenient for commercial kitchens. For instance, a foodservice distributor might supply a restaurant with 5-gallon containers of cooking oil or large packs of frozen vegetables.

Retail products, by contrast, are packaged in consumer-friendly sizes and are often labeled with nutritional information and branding that appeals to end consumers. The packaging for retail products is designed to be attractive and informative, influencing purchasing decisions at the point of sale.

| Distribution Channel | Packaging Requirements | Service Model |

|---|---|---|

| Foodservice | Bulk or commercial packaging | Includes menu planning, inventory management |

| Retail | Consumer-sized packaging | Focuses on inventory management, shelf stocking |

Wholesale Food Distributors Open to the Public

Some wholesale food distributors cater to both foodservice businesses and the general public. These distributors often operate cash-and-carry models or membership-based stores where customers can purchase products in bulk or at wholesale prices. This model is particularly popular among small businesses, such as food trucks or catering services, that benefit from wholesale pricing but may not qualify as traditional foodservice operators.

Consumers also benefit from these distributors, as they can purchase specialty or gourmet products in bulk. Examples include distributors like Sysco or US Foods that have cash-and-carry locations or specialty stores that serve both commercial and retail customers.

How to Choose a Food Distributor for Your Business

In the complex landscape of food distribution, identifying the ideal partner requires a strategic approach. Choosing the right food distributor is crucial for maintaining a smooth supply chain and ensuring the timely delivery of high-quality products to your customers.

Assessing Your Distribution Needs

The first step in selecting a food distributor is to assess your business’s specific distribution needs. This involves understanding your product requirements, delivery schedules, and any special handling needs.

- Product range and specialty items

- Delivery frequency and lead times

- Storage and handling requirements

- Geographic coverage needed

By clearly defining your distribution needs, you can narrow down your search to distributors who are well-equipped to meet your requirements.

Evaluating Distributor Capabilities and Coverage

Once you have a clear understanding of your distribution needs, the next step is to evaluate potential distributors based on their capabilities and coverage. This includes assessing their:

- Product offerings and supplier relationships

- Logistics and delivery capabilities

- Technology and inventory management systems

- Geographic reach and regional expertise

A thorough evaluation will help you identify distributors who can reliably meet your needs and support your business growth.

Questions to Ask Potential Distribution Partners

When engaging with potential food distributors, it’s essential to ask the right questions to gauge their suitability for your business. Some key questions to consider include:

| Category | Sample Questions |

|---|---|

| Product and Supply Chain | What is your product range? How do you manage supplier relationships? |

| Logistics and Delivery | What are your delivery lead times? How do you handle order fulfillment and tracking? |

| Technology and Systems | What inventory management systems do you use? How do you integrate with customers’ ordering systems? |

Comparing Proposals and Service Offerings

After gathering information from potential distributors, the final step is to compare their proposals and service offerings. This involves evaluating their pricing structures, service level agreements, and any value-added services they provide.

By carefully comparing these factors, you can make an informed decision that aligns with your business objectives and ensures a successful partnership with your chosen food distributor.

Negotiating Distributor Agreement Terms

Negotiating the terms of a distributor agreement is a critical step in establishing a successful partnership. A distributor agreement outlines the responsibilities, obligations, and expectations of both the distributor and the supplier, serving as a roadmap for their business relationship.

Standard Contract Elements

A typical distributor agreement includes several standard elements that form the foundation of the contract. These may include:

- Definitions: Clear definitions of key terms used in the agreement to avoid misunderstandings.

- Scope of Work: A detailed description of the services to be performed by the distributor.

- Term and Termination: Provisions outlining the duration of the agreement and the conditions under which it can be terminated.

- Obligations: Specific responsibilities of both parties, such as inventory management, sales targets, and customer service expectations.

Pricing Structures and Volume Commitments

Pricing structures and volume commitments are critical components of a distributor agreement. Suppliers often offer tiered pricing based on the volume of products purchased, incentivizing larger orders. It’s essential to negotiate pricing that aligns with your business model and sales projections.

Volume commitments can also impact pricing and should be carefully considered. Distributors may be required to purchase a minimum quantity of products within a specified timeframe to maintain their pricing level or to avoid penalties.

Exclusivity Clauses and Territory Rights

Exclusivity clauses and territory rights are significant aspects of distributor agreements. An exclusivity clause may grant a distributor exclusive rights to sell certain products within a defined territory, preventing the supplier from appointing other distributors in that area.

When negotiating exclusivity clauses, it’s crucial to define the territory clearly and understand the implications of exclusivity on your business and the supplier’s operations.

Payment Terms and Credit Policies

Payment terms and credit policies are vital elements of a distributor agreement, as they directly affect cash flow and financial planning. Distributors should negotiate payment terms that align with their financial capabilities and business needs.

Credit policies, including credit limits and payment periods, should be clearly outlined in the agreement to avoid potential disputes.

Key Performance Metrics in Food Distribution

Key performance metrics play a pivotal role in the food distribution sector, influencing decision-making and operational efficiency. Distributors rely on these metrics to evaluate their performance, identify areas for improvement, and make data-driven decisions.

Fill Rates and Order Accuracy

Fill rates and order accuracy are critical metrics in food distribution. Fill rate refers to the percentage of customer orders that are fulfilled completely, without any stockouts or backorders. A high fill rate indicates that a distributor is effectively managing its inventory and meeting customer demand. Order accuracy, on the other hand, measures the percentage of orders that are delivered correctly, without any errors or discrepancies.

According to industry benchmarks, a fill rate of 95% or higher is considered excellent, while order accuracy should ideally be above 99%. Achieving high fill rates and order accuracy requires robust inventory management systems, efficient logistics, and a strong focus on customer service.

On-Time Delivery Performance

On-time delivery is another crucial metric in food distribution, as it directly impacts customer satisfaction and loyalty. On-time delivery performance measures the percentage of orders that are delivered within the agreed-upon timeframe. Distributors strive to achieve on-time delivery rates of 95% or higher, as delays can result in lost sales, damaged relationships, and reputational harm.

To improve on-time delivery performance, distributors can invest in route optimization software, implement just-in-time inventory management, and develop contingency plans for unexpected disruptions.

Credit Rates and Returns Management

Credit rates and returns management are also important metrics in food distribution. Credit rates refer to the percentage of sales that are credited back to customers due to product returns, damages, or other issues. Effective returns management involves streamlining the returns process, identifying root causes of returns, and implementing corrective actions to minimize future returns.

“A well-managed returns process can turn a negative experience into a positive one, fostering customer loyalty and driving long-term growth.” – Industry Expert

By closely monitoring credit rates and returns management, distributors can identify opportunities to improve their operations, reduce costs, and enhance customer satisfaction.

Cold Chain Distribution and Food Safety

The cold chain distribution process is essential for ensuring the quality and safety of temperature-sensitive food products. This complex process involves maintaining precise temperature control throughout the supply chain, from production to consumption.

Temperature Control Requirements

Temperature control is critical in cold chain distribution. Different products require specific temperature ranges to maintain their quality and safety. For instance, frozen foods need to be kept at -18°C or lower, while refrigerated products typically require temperatures between 1°C and 8°C.

To achieve these temperature requirements, distributors use specialized equipment such as refrigerated trucks, cold storage facilities, and refrigerated packaging. The use of data loggers and temperature monitoring systems helps to ensure that products remain within the required temperature range during transportation and storage.

“The integrity of the cold chain is paramount to preventing foodborne illnesses and maintaining the quality of perishable goods.” –

Food Safety Expert

Equipment and Technology for Cold Chain Integrity

The integrity of the cold chain relies on advanced equipment and technology. Some of the key elements include:

- Refrigerated transportation: Trucks and containers equipped with refrigeration units to maintain the required temperatures.

- Cold storage facilities: Warehouses with climate-controlled environments for storing perishable goods.

- Refrigerated packaging: Insulated packaging that helps maintain product temperatures during shipping.

- Temperature monitoring systems: Real-time monitoring of product temperatures to quickly identify and address any deviations.

| Equipment | Description | Temperature Range |

|---|---|---|

| Refrigerated Trucks | Transportation of perishable goods | -30°C to 30°C |

| Cold Storage Facilities | Storage of perishable goods | -25°C to 8°C |

| Refrigerated Packaging | Insulated packaging for shipping | -20°C to 15°C |

Compliance with Food Safety Regulations

Compliance with food safety regulations is crucial for cold chain distributors. Regulations such as the Food Safety Modernization Act (FSMA) in the United States mandate strict guidelines for handling, storing, and transporting food products.

Distributors must implement robust food safety plans, conduct regular audits, and maintain detailed records to demonstrate compliance. Training personnel on food safety practices and maintaining clean, sanitary facilities are also essential components of a compliant operation.

By prioritizing cold chain integrity and compliance with food safety regulations, distributors can ensure the safe delivery of high-quality food products to consumers.

Food Distributors and Traceability Requirements

In the complex world of food distribution, traceability has emerged as a critical component in ensuring consumer safety. Traceability refers to the ability to track the movement of food products through the supply chain, from origin to consumption.

The importance of traceability cannot be overstated, as it enables quick identification and recall of contaminated or unsafe food products, thereby protecting public health. Effective traceability systems are essential for food distributors to maintain compliance with regulatory requirements and to uphold consumer trust.

Track and Trace Systems

Track and trace systems are designed to monitor the movement of food products throughout the distribution network. These systems utilize a combination of technologies, including barcode scanning, RFID, and data analytics, to provide real-time visibility into product location and status.

Key components of track and trace systems include:

- Unique product identifiers

- Data capture and storage

- Real-time tracking capabilities

- Integration with existing supply chain systems

Recall Procedures and Protocols

In the event of a food safety issue, effective recall procedures are crucial to minimize risk to consumers and protect the distributor’s reputation. Recall protocols should be well-defined, regularly tested, and communicated to all stakeholders.

Best practices for recall procedures include:

- Clear identification of responsible personnel

- Rapid notification systems

- Accurate inventory management

- Effective communication with regulatory agencies and customers

Technology Solutions for Enhanced Traceability

Advancements in technology have significantly enhanced traceability in food distribution. Solutions such as blockchain, IoT devices, and advanced data analytics are being adopted to improve tracking accuracy and speed.

| Technology | Description | Benefits |

|---|---|---|

| Blockchain | Decentralized ledger technology for secure data storage | Enhanced security, transparency, and accountability |

| IoT Devices | Real-time monitoring of temperature, humidity, and location | Improved product quality control, reduced spoilage |

| Data Analytics | Advanced analysis of supply chain data | Better insights into supply chain operations, predictive capabilities |

By leveraging these technologies, food distributors can enhance their traceability capabilities, ensuring compliance with regulations and building trust with consumers.

Regulatory Considerations for Food Distributors

Navigating the complex regulatory landscape is crucial for food distributors operating in the U.S. market. The industry is subject to a myriad of regulations designed to ensure food safety, compliance, and fair business practices.

FDA Regulations and Compliance

The Food and Drug Administration (FDA) plays a pivotal role in overseeing the food distribution industry. FDA regulations encompass a wide range of requirements, including food safety standards, labeling requirements, and good manufacturing practices (GMPs). Food distributors must ensure compliance with these regulations to avoid legal issues and maintain public trust.

PACA for Produce Distributors

The Perishable Agricultural Commodities Act (PACA) is a critical regulation for produce distributors. It aims to protect the rights of growers, shippers, and distributors of perishable agricultural commodities. PACA requires produce distributors to be licensed and adhere to strict payment terms and record-keeping requirements. Compliance with PACA is essential for maintaining the integrity of the produce supply chain.

State-Specific Distribution Requirements

In addition to federal regulations, food distributors must also comply with state-specific requirements. These can include licensing, labeling, and packaging regulations that vary from state to state. Understanding and adhering to these regulations is crucial for distributors operating in multiple states.

Food Safety Modernization Act (FSMA) Impact

The Food Safety Modernization Act (FSMA) represents a significant shift in food safety regulation, focusing on prevention rather than response. FSMA requires food distributors to implement preventive controls, conduct regular inspections, and maintain detailed records. The act has a profound impact on the food distribution industry, enhancing safety and reducing the risk of contamination.

In conclusion, regulatory compliance is a multifaceted challenge for food distributors. By understanding and adhering to FDA regulations, PACA, state-specific requirements, and FSMA, distributors can ensure operational integrity, maintain public trust, and contribute to a safer food supply chain.

Vendor Onboarding and Technology Integration

Technology plays a pivotal role in enhancing the efficiency of vendor onboarding in food distribution. Effective vendor onboarding is crucial for establishing a seamless and efficient supply chain. By leveraging technology, food distributors can streamline their operations, reduce costs, and improve customer satisfaction.

The Vendor Onboarding Checklist

A comprehensive vendor onboarding checklist is essential for ensuring that all necessary steps are taken when integrating new vendors into the distribution network. This checklist should include verifying vendor credentials, setting up EDI systems, and establishing clear communication channels.

The key elements of a vendor onboarding checklist include:

- Vendor credential verification

- EDI system setup and testing

- Inventory management system integration

- Route optimization software implementation

EDI Systems for Food Suppliers

Electronic Data Interchange (EDI) systems enable the electronic exchange of business documents between suppliers and distributors. Implementing EDI systems can significantly reduce paperwork, improve accuracy, and speed up the ordering process.

| Benefits of EDI Systems | Description |

|---|---|

| Reduced Paperwork | Automates the exchange of business documents |

| Improved Accuracy | Minimizes errors through standardized data formats |

| Faster Ordering Process | Enables real-time communication between suppliers and distributors |

Inventory Management Solutions

Effective inventory management is critical for food distributors to ensure they have the right products in stock at the right time. Inventory management solutions help distributors track inventory levels, manage orders, and optimize storage.

Key Features of Inventory Management Solutions:

- Real-time inventory tracking

- Automated order management

- Optimized storage and warehouse management

Route Optimization and Logistics Software

Route optimization software is designed to help distributors plan the most efficient delivery routes, reducing transportation costs and improving delivery times. By integrating route optimization with logistics software, distributors can further enhance their operational efficiency.

By integrating technology into vendor onboarding and distribution operations, food distributors can achieve significant improvements in efficiency, accuracy, and customer satisfaction. As the food distribution industry continues to evolve, the adoption of advanced technologies will be crucial for staying competitive.

The Future of Food Distribution in America

The food distribution landscape in the U.S. is evolving rapidly, driven by technological innovations and changing consumer preferences. As we’ve explored throughout this article, the industry is characterized by a complex supply chain, diverse distribution networks, and a range of players from broadline distributors to specialty food distributors.

Looking ahead, the future of food distribution will be shaped by trends such as the adoption of digital technologies, including artificial intelligence and blockchain, to enhance supply chain efficiency and transparency. Innovations in logistics and transportation will also play a crucial role in meeting the demands of a rapidly changing market.

As consumer preferences continue to shift towards sustainability and convenience, food distributors will need to adapt by investing in eco-friendly practices and flexible delivery options. Companies like Sysco, US Foods, and Performance Food Group are already leading the way in embracing these trends, leveraging their scale and resources to drive innovation.

The future of food distribution in America will be characterized by continued evolution and innovation, driven by technological advancements and changing consumer needs.

FAQ

What is a food distributor?

A food distributor is a company that acts as an intermediary between food producers and consumers, supplying restaurants, stores, and other foodservice businesses with a wide range of food products.

What are the different types of food distributors?

There are several types of food distributors, including broadline distributors, specialty food distributors, and regional or national distribution networks, each with their unique features and benefits.

How do I choose the right food distributor for my business?

To choose the right food distributor, you need to assess your distribution needs, evaluate distributor capabilities, compare proposals, and consider factors such as product offerings, delivery schedules, and pricing structures.

What is the role of food distributors in ensuring food safety?

Food distributors play a crucial role in maintaining food safety by adhering to temperature control requirements, using proper equipment and technology, and complying with food safety regulations, such as those set by the FDA.

What is cold chain distribution, and why is it important?

Cold chain distribution refers to the transportation and storage of perishable goods at a controlled temperature to maintain their quality and safety. It is essential for preventing spoilage and ensuring the integrity of food products.

What is PACA, and how does it impact produce distributors?

PACA (Perishable Agricultural Commodities Act) is a federal law that regulates the produce industry, requiring produce distributors to be licensed and adhere to certain standards, including fair business practices and payment terms.

What is EDI, and how is it used in food distribution?

EDI (Electronic Data Interchange) is a technology that enables the electronic exchange of business documents, such as orders and invoices, between companies. In food distribution, EDI is used to streamline communication, improve efficiency, and reduce errors.

How do food distributors ensure traceability?

Food distributors use track and trace systems, recall procedures, and technology solutions to enhance traceability, allowing them to quickly identify and recall products in case of a food safety issue.

What are the key performance metrics in food distribution?

Key performance metrics in food distribution include fill rates, order accuracy, on-time delivery, and returns management, which help distributors measure their efficiency and effectiveness.

How do food distributors handle vendor onboarding?

Food distributors use a vendor onboarding checklist to ensure that new suppliers meet their requirements, including product quality, packaging, and delivery standards.

What is the impact of the Food Safety Modernization Act on food distributors?

The Food Safety Modernization Act has increased regulations and requirements for food distributors, including enhanced record-keeping, preventive controls, and compliance with FDA regulations.

Do food distributors work with small farms and new brands?

Yes, but food distributors often require basic documentation, consistent case specs, and a minimum order flow that fits their routes, so being “small” is fine if you are operationally ready. Market support programs and resources (USDA AMS)

What documents should I request before onboarding?

Ask food distributors for insurance requirements, vendor setup forms, service level expectations, returns/credits policy, and any food safety audit expectations, then compare them to your current capabilities to avoid surprise costs. Starting and operating a food business basics (FDA)

How do I compare distributor quotes fairly?

Compare food distributors using total delivered cost assumptions: delivery frequency, minimums, fees, promotional terms, and expected credit rate, then model a few “real” order baskets rather than a single SKU price.

What’s the biggest hidden risk in distribution?

The biggest hidden risk with food distributors is uncontrolled service variability—late deliveries, substitutions without approval, and slow credit resolution—which can create churn with your customers even when the product is good.

How fast can a distributor help me expand to new states?

Food distributors can speed expansion if they already serve the region and can add your items quickly, but timelines still depend on item setup, slotting in warehouse locations, and buyer approval cycles in the target channel. Regional market and workforce context (BLS)

Conclusion of: Food Distributors In USA

In the U.S., food distributors sit between producers and buyers, helping farms, brands, and manufacturers reach restaurants, institutions, and retailers without running their own delivery fleet or warehouse network. This guide breaks down how wholesale distribution really works and what to look for before you sign an agreement with food distributors. Wholesale trade industry overview (BLS)

Because food moves under tight time and temperature constraints, the right partner can reduce waste, improve fill rates, and make compliance easier, while the wrong partner can create costly backorders and quality complaints. You’ll learn the practical questions to ask, the documents to request, and the metrics that separate reliable food distributors from frustrating ones.

What wholesalers do (and why they exist)

At their core, food distributors aggregate products from many suppliers, store them safely, break bulk into buyer-sized orders, and deliver on predictable schedules. This matters in a country as large as the U.S., where freight lanes, seasonality, and buyer requirements can change quickly and stress small shippers. NAICS classification for U.S. industries (U.S. Census)

Many food distributors also provide services that buyers rely on, such as product substitutions during shortages, menu or assortment guidance, and documented lot tracking for recalls. If you sell into restaurants or schools, that service layer often becomes as important as price, especially when deliveries are frequent and orders are small. Foodservice distribution industry association (IFDA)

How wholesale distribution works step by step

Most food distributors start with supplier onboarding, where they confirm licenses, food safety documentation, insurance, and basic traceability information before a single case ships. This protects the distributor and their customers by ensuring they can prove what they bought, from whom, and under what conditions.

Next comes purchasing, where food distributors forecast demand, negotiate pricing tiers, and schedule inbound deliveries to match warehouse capacity and customer delivery calendars. A strong buyer uses historical order patterns, seasonal shifts, and promotion calendars to avoid overstock and out-of-stocks that create waste. Market price and volume reporting (USDA AMS)

Receiving is where food distributors protect quality by inspecting loads, verifying counts, and documenting temperatures for refrigerated and frozen items. In a well-run facility, receiving also assigns lot codes and storage locations immediately so products can be traced and rotated accurately. Warehouse safety guidance (OSHA)

Storage and rotation are the quiet engines of performance for food distributors, because proper zoning (ambient, refrigerated, frozen) and FIFO/FEFO practices determine how much product is lost to spoilage. When you tour a warehouse, pay attention to dock discipline, temperature monitoring, and how quickly product moves from receiving to put-away. Postharvest handling and cold chain resources (UC Davis)

Order picking is where food distributors convert bulk inventory into accurate customer orders, and accuracy here drives your real cost per case. Barcode scanning, checkweighing, and structured pick paths reduce shorts, mis-picks, and customer credits that can silently erase margin. Barcode and product identification standards (GS1 US)

Delivery is where food distributors either earn trust or lose it, because on-time performance affects staffing, production timing, and menu availability for customers. For refrigerated routes, loads must be built to protect airflow and temperature stability, and drivers need procedures for temperature excursions.

Major types of distributors you’ll encounter

Broadline food distributors carry thousands of SKUs across categories, making them convenient for restaurants and institutions that want fewer vendors and fewer deliveries. Specialty distributors focus on niches like produce, meat, dairy, seafood, or natural/organic lines, often offering deeper expertise and fresher turns within their category. Food retail and supply chain industry resources (FMI)

There are also regional food distributors that win on local coverage and relationships, plus national networks that offer multi-state service and standardized reporting. Choosing between them depends on where your customers are, your required delivery frequency, and how complex your product handling requirements are. Restaurant industry context and operations (National Restaurant Association)

- Broadline: one-stop ordering, large footprint, standardized service

- Specialty: deeper category expertise, faster turns, tighter handling specs

- Regional: strong local routes and relationships, flexible service

- National: consistent systems across markets, formal vendor requirements

How distributors make money (so you can negotiate intelligently)

Most food distributors earn margin through a markup between their acquisition cost and your selling price, but the “true” cost is shaped by service requirements like delivery frequency, minimum drop size, and returns. Two customers can buy the same case and pay different effective prices because the service cost to deliver can be very different.

Some food distributors also use rebates, volume incentives, and promotional allowances that flow through from manufacturers, which can complicate quote comparisons. To compare apples to apples, ask for the pricing structure (cost-plus, delivered price, or tiered brackets) and clarify which fees or credits can change month to month. Sales contract principles (UCC Article 2)

Compliance and food safety checkpoints that matter

Even though food distributors may not “manufacture” product, they still influence food safety through storage, handling, and transportation controls. A credible partner will show written SOPs for temperature monitoring, sanitation, pest control, and corrective actions when limits are exceeded. Food safety fundamentals (CDC)

For fresh produce, many food distributors operate under requirements shaped by the Perishable Agricultural Commodities Act (PACA), especially around fair trading and dispute resolution. If produce is part of your mix, understanding PACA protections and documentation norms can prevent painful payment and quality disputes. PACA program information (USDA AMS)

For meat and poultry items that pass through warehouses, food distributors need strong controls to prevent cross-contamination and to maintain cold chain integrity. Ask how they separate raw and ready-to-eat items, how they handle damaged packages, and what their hold-and-release procedures look like for suspect product. Meat and poultry safety resources (USDA FSIS)

Transport is a recurring weak point for food distributors, because a single warm trailer can ruin thousands of dollars of product and trigger customer chargebacks. Ask whether they use validated temperature recording, how they respond to equipment failures, and what documentation you receive when a temperature excursion occurs.

Traceability, labeling, and data standards

Modern food distributors rely on product IDs, lot codes, and standardized item data so they can trace product quickly during a withdrawal or recall. If your products are not consistently labeled with scannable identifiers, your onboarding will be slower and your error rate can spike. Recall process overview (FDA)

The FDA Food Traceability Rule is pushing more detailed recordkeeping for certain foods, and food distributors will increasingly expect suppliers to support rapid, digital trace requests. Even if your product is not on the Food Traceability List, buyers often apply similar expectations because it reduces risk and downtime during investigations.

Weights, measures, and accurate case counts are operational details that can become financial disputes, especially when food distributors sell by weight, pack, or catch-weight. Clear specs, consistent labeling, and documented tolerances reduce credits, short pays, and customer dissatisfaction.

When to use a distributor instead of selling direct

Using food distributors makes the most sense when you need route density, frequent delivery, invoice consolidation, and access to buyers who prefer “one order, one truck, one bill.” Direct sales can still be great for large, predictable customers, but it often becomes costly when you add small drops, returns, and route planning. U.S. food system context (USDA)

Food distributors can also accelerate market entry because they already have approved vendor lists, item setup processes, and buyer relationships. If you’re launching a new SKU, a distributor’s merchandising and sales team can sometimes help you get trial placement faster than going door-to-door yourself. Market research basics for suppliers (SBA)

How to evaluate a distributor before you commit

Start by defining what you need from food distributors: service area, minimum delivery frequency, temperature zones, order cut-off times, and expected fill rate. Without a written service profile, you’ll compare quotes that hide different assumptions, and the “cheapest” partner may become the most expensive after credits and stockouts. Audit and verification services overview (USDA AMS)

Next, assess operational capability by asking food distributors for proof, not promises—delivery performance reports, error/credit rates, and examples of corrective action. A short facility tour can reveal more than a sales pitch, especially if you watch receiving, picking, and outbound staging in real time.

Quality systems matter because food distributors touch product at multiple points, so ask what third-party audits they hold (SQF, BRCGS, or similar) and how often they train staff on hygiene and temperature control. If you cannot get a clear answer on corrective actions and recordkeeping, treat that as a red flag. SQF program overview (SQFI)

Finally, check customer fit by asking food distributors for references in your segment (restaurants, institutions, retailers, or processors) and by reviewing their SKU catalog depth. A partner that is perfect for broadline restaurant deliveries may be a poor fit for specialty retail compliance requirements.

Quick checklist

Use this quick screen to compare food distributors consistently, even when proposals look different on paper. Sanitation and antimicrobial basics (EPA)

- Service area coverage and delivery days match your customer map

- Temperature zones available (ambient/refrigerated/frozen) with monitoring

- Cut-off times and lead times fit your production schedule

- Fill-rate and on-time targets are defined in writing

- Lot tracking and recall response time expectations are documented

- Third-party audit status and corrective action process are available

- Returns, credits, and damage policies are transparent

- Minimum order size and delivery fees are clearly stated

- EDI/item setup process and timeline are realistic

- Insurance requirements and liability terms are understood

Common mistakes to avoid

Most “bad distributor stories” happen because suppliers skip due diligence with food distributors or assume standard terms that were never agreed to. Preventive controls concept (FDA)

- Choosing on price alone: compare total delivered cost after credits, errors, and stockouts.

- Not defining service levels: require targets for fill rate, on-time, and credit processing time.

- Weak item setup data: provide consistent GTINs, case pack, allergens, and storage specs from day one.

- Ignoring temperature proof: ask for logs and how excursions are documented and corrected.

- Overlooking returns policy: clarify shelf-life minimums, damage claims, and rejected-load rules.

- No escalation path: get named contacts for operations, billing, and quality issues.

- Underestimating MOQs: confirm minimums by category and by route, not just “per order.”

- Skipping reference checks: talk to customers who buy similar products at similar volumes.

Costs and ROI snapshot

When budgeting food distributors, think in cost drivers rather than a single markup: delivery frequency, minimum drop size, returns, temperature zones, and the number of SKUs you carry all move the total. Many suppliers find that fewer failed deliveries and fewer credits can offset a higher nominal price. Pricing and cost trend context (BLS PPI)

For many U.S. farms and small brands, ROI from food distributors shows up as reduced spoilage, fewer administrative hours, faster market entry, and steadier reorder patterns rather than dramatic margin gains. Track measurable outcomes like order accuracy, time-to-cash, shrink reduction, and customer retention to decide if the relationship is paying off. U.S. production seasonality context (USDA NASS)

Three real-world scenarios (and what to ask)

If you sell fresh produce, food distributors are often evaluated on cold chain discipline, turn speed, and their ability to handle grade variability without constant claims. Ask how they manage ripeness windows, how they rotate inventory, and what they require for PACA documentation and dispute resolution. Produce safety and handling resources (Cornell)

If you sell to restaurants, food distributors are often judged by fill rate, substitutions, and delivery-time reliability because a missing item can break a menu for a night. Ask how substitutions are approved, how they communicate shortages, and whether you can access order and performance reporting in a portal. Foodservice operations and trends (NRA Research)

If you sell packaged shelf-stable items, food distributors are typically evaluated on pick accuracy, damage rates, and case handling that prevents crushed packaging and barcode failures. Ask about pallet patterns, case pack requirements, and whether they use scan verification at pick and load.

Negotiating the agreement

Before signing, align with food distributors on payment terms, credit timing, dispute resolution, and who pays for freight or temperature-related losses. Put service-level expectations in writing, including how quickly issues must be acknowledged and resolved, because “we’ll take care of it” is not a contract clause. Supply chain protection concepts (FDA Food Defense)

Onboarding and your first 30 days

The first month with food distributors should focus on clean item setup, reliable ordering cadence, and fast feedback loops on errors. Start with a controlled SKU set, review credits weekly, and agree on a routine performance review so small problems don’t become “normal.”

KPIs to track after you choose a partner

To manage food distributors well, track fill rate, on-time delivery, order accuracy, credit rate, damage rate, and days-to-pay, then review trends rather than one-off incidents. When you can quantify the operational impact, it becomes much easier to negotiate improvements and justify staying or switching.

Final thought

The best relationships with food distributors are built on clear service expectations, clean product data, and measurable performance reviews that keep quality and cost aligned as you grow. If you treat selection like a systems decision—not just a price decision—you’ll protect your brand and make distribution a competitive advantage.

Sources & References

- List of Wholesale Food Distributors in USA

- Sysco | Wholesale Restaurant Food Distributor

- Best Hispanic Food Distributor In The U.S.

- McLane Foodservice

- Performance Foodservice

- Gordon Food Service

- Reinhart Foodservice

- The Martin-Brower Co.

- DOT Transportation

- Ben E. Keith Co.

- Golden State Foods

- Shamrock Foods Co.

- KeHE Distributors

- PFG Customized

- Vistar Transportation

- Buffalo Rock Co.

- FSMA rules and guidance for industry (FDA)

- Transportation and market analysis resources (USDA AMS)

- Inspection and food safety oversight (USDA FSIS)

- Food systems overview (FAO)

- Food labeling and nutrition resources (FDA)