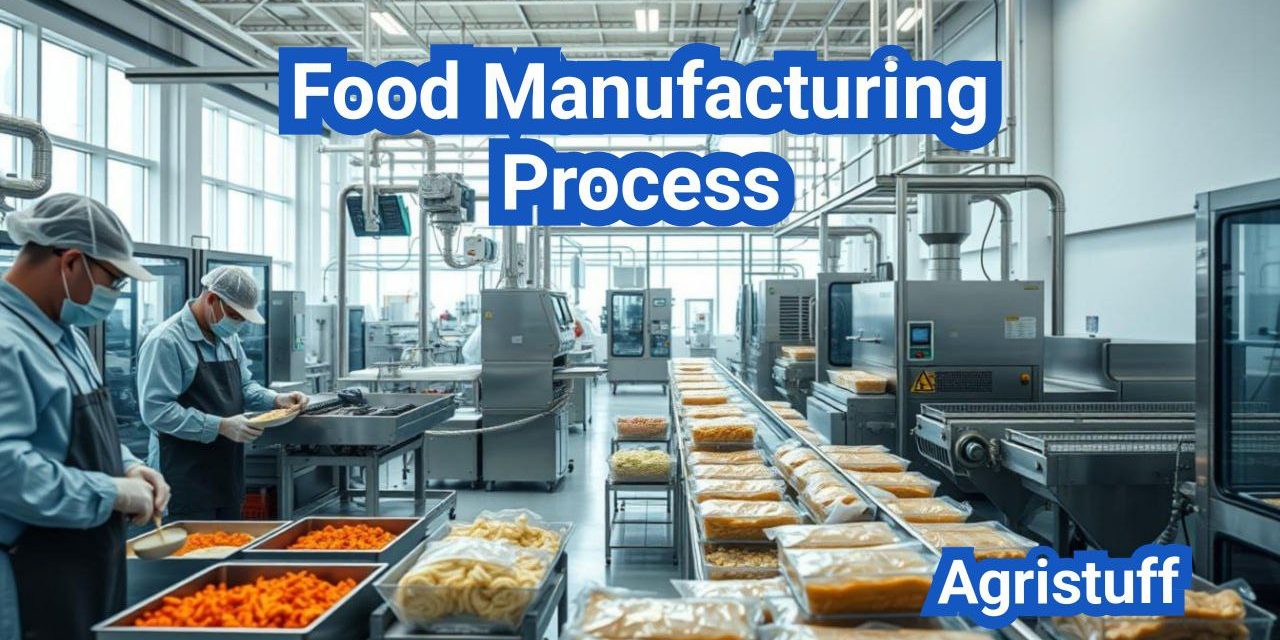

The food manufacturing process involves transforming raw agricultural materials into consumable food products. This complex process includes various stages such as cleaning, processing, packaging, and distribution.

In the United States, the food manufacturing industry plays a vital role in ensuring a stable food supply. The process flow typically begins with sourcing raw materials, followed by preparation, cooking, packaging, and finally, distribution to retailers.

Key Takeaways

- Understanding the food manufacturing process is crucial for ensuring food safety.

- The food manufacturing process flow involves multiple stages, from raw material sourcing to finished goods.

- Efficient food processing and packaging are essential for maintaining product quality.

- The U.S. food manufacturing industry is heavily regulated to ensure compliance with safety standards.

- A well-managed food manufacturing process can improve productivity and reduce costs.

The Evolution of Food Manufacturing in the United States

From traditional preservation methods to modern industrial processes, the evolution of food manufacturing in the U.S. has been a journey of innovation and adaptation. The history of food manufacturing dates back to ancient times when communities first began preserving their harvests to sustain themselves throughout the year.

The Industrial Revolution marked a significant turning point in the development of food manufacturing, introducing large-scale production facilities that could process and preserve food on a much larger scale. This period saw the introduction of new technologies and manufacturing processes that transformed the industry.

Historical Development of Food Processing

The historical development of food processing is a story of continuous innovation. Early methods included smoking, salting, and fermenting, which were later supplemented by canning and freezing techniques. The 20th century saw the advent of more sophisticated processing technologies, including pasteurization and sterilization.

These advancements allowed for the mass production of a wide range of food products, from canned goods to frozen meals. The development of new packaging materials and technologies further expanded the possibilities for food processing and distribution.

Economic Impact of the Food Manufacturing Industry

The food manufacturing industry has a significant economic impact on the U.S. economy. It is one of the largest manufacturing sectors, providing employment for millions of people and generating substantial revenue. The industry’s economic influence extends beyond its direct contributions, supporting related sectors such as agriculture and transportation.

The economic impact is also felt in rural areas where food processing facilities are often located, providing vital employment opportunities and contributing to local economies.Modern Innovations Shaping Food Production \

Today, the food manufacturing industry continues to evolve, driven by modern innovations such as automation, robotics, and advanced food processing technologies. These innovations are improving efficiency, reducing costs, and enabling the production of higher-quality food products.

Some of the key modern innovations include the use of artificial intelligence and machine learning to optimize production processes, the development of new food processing methods that preserve nutritional value, and the integration of sustainable practices into manufacturing operations.

These advancements are not only enhancing the competitiveness of the U.S. food manufacturing industry but also helping to meet changing consumer demands for safer, more nutritious, and more sustainably produced food products.

Overview of the Food Manufacturing Process

Understanding the food manufacturing process is crucial for ensuring the quality and safety of the final product. The food manufacturing process involves several steps, including sourcing raw materials, pre-processing, processing, packaging, and distribution.

End-to-End Food Manufacturing Process Flow

The end-to-end food manufacturing process flow encompasses all stages from raw material sourcing to the delivery of the final product. This includes:

- Raw material procurement and inspection

- Pre-processing and preparation

- Primary and secondary processing

- Packaging and labeling

- Storage and distribution

Creating and Interpreting Process Flow Diagrams

Process flow diagrams are essential tools in food manufacturing, providing a visual representation of the production process. These diagrams help in identifying potential hazards and critical control points where safety measures can be implemented.

To create effective process flow diagrams, manufacturers must consider the entire production process, from raw material intake to final product packaging. This involves:

- Mapping out each stage of the process

- Identifying potential risks and hazards

- Implementing controls to mitigate these risks

Role of Process Engineers in Food Manufacturing

Process engineers play a crucial role in ensuring the efficiency and safety of the food manufacturing process. They are responsible for designing, implementing, and maintaining the production process, ensuring compliance with food safety regulations.

Their tasks include:

- Developing and optimizing production processes

- Implementing quality assurance measures

- Ensuring compliance with food safety standards

Critical Control Points in Production | Food Manufacturing Process

Critical control points (CCPs) are stages in the food manufacturing process where controls can be applied to prevent, eliminate, or reduce food safety hazards. Identifying CCPs is crucial for developing effective food safety plans.

Examples of CCPs include:

- Cooking and heat treatment

- Refrigeration and storage

- Metal detection and foreign body control

Raw Material Sourcing and Preparation

Raw material sourcing and preparation are crucial elements that determine the quality of the final food product. The process involves several key steps and considerations to ensure that the raw materials used are safe, of high quality, and suitable for consumption.

Supplier Approval Programs | Food Manufacturing Process

One of the initial steps in raw material sourcing is the implementation of supplier approval programs. These programs involve evaluating and approving suppliers based on their ability to meet quality and safety standards. This includes assessing their production processes, quality control measures, and compliance with regulatory requirements.

- Evaluation of supplier facilities and processes

- Assessment of quality control measures

- Review of compliance with food safety regulations

Quality Standards for Ingredients | Food Manufacturing Process

Establishing quality standards for ingredients is vital to ensure that raw materials meet the required specifications. This involves setting clear criteria for the acceptance of raw materials, including parameters such as freshness, purity, and absence of contaminants.

- Defining specifications for raw materials

- Conducting regular audits of suppliers

- Implementing testing protocols for raw materials

Initial Processing and Handling of Raw Materials

The initial processing and handling of raw materials play a significant role in maintaining their quality. Proper handling practices prevent contamination and damage, ensuring that raw materials remain in good condition until they are used in production.

Inventory Management Systems | Food Manufacturing Process

Effective inventory management systems are essential for tracking and managing raw materials. These systems help in maintaining optimal stock levels, reducing waste, and ensuring that raw materials are used within their shelf life.

- Tracking inventory levels and movement

- Managing stock rotation and shelf life

- Minimizing waste and overstock

Primary Processing Techniques in Food Manufacturing

Primary processing techniques are fundamental to food manufacturing, encompassing various methods to process raw materials into food products. These techniques are crucial for transforming raw ingredients into consumable goods, ensuring safety, quality, and consistency.

Mechanical Processing Methods | Food Manufacturing Process

Mechanical processing involves physical methods to alter the size, shape, or texture of food materials. Common techniques include grinding, milling, cutting, and sorting. For instance, grinding is used to produce flours from grains, while cutting is essential for preparing uniform vegetable or meat products.

Grinding and Milling: These processes reduce particle size, enhancing the texture and mixability of ingredients. Advanced milling technologies can produce fine powders or adjust particle sizes according to specific product requirements.

Thermal Processing Techniques | Food Manufacturing Process

Thermal processing involves the application of heat to achieve desired changes in food products, such as cooking, pasteurization, or sterilization. Techniques include blanching, retorting, and extrusion cooking.

Pasteurization: This process involves heating food to a specific temperature to kill harmful bacteria, extending shelf life while maintaining nutritional value. It’s commonly used for dairy products and juices.

Chemical Processing Applications | Food Manufacturing Process

Chemical processing in food manufacturing involves the use of additives or chemical reactions to enhance product characteristics. This includes preservation through acidification or the use of antimicrobial agents, as well as modifying food texture and flavor.

Preservation Techniques: Chemical preservatives are used to prevent spoilage and extend shelf life. Examples include the use of sulfites in dried fruits and sodium benzoate in beverages.

Secondary Processing and Formulation

Secondary processing is a critical phase in food manufacturing that involves transforming raw ingredients into final products through various techniques. This stage is crucial for developing the desired characteristics of food products, including texture, flavor, and nutritional content.

Mixing and Blending Operations | Food Manufacturing Process

Mixing and blending are fundamental operations in secondary processing, used to combine ingredients in specific proportions to achieve a uniform product. Effective mixing ensures that all components are evenly distributed, which is critical for product quality and consistency.

The choice of mixing technique depends on the nature of the ingredients and the desired product characteristics. Common mixing methods include dry mixing, wet mixing, and high-shear mixing, each suited to different types of food products.

Extrusion Technology in Food Production

Extrusion is a versatile processing technique used to create a wide range of food products, from snacks and cereals to pasta and textured proteins. Extrusion technology involves forcing a mixture of ingredients through a die to shape the product and achieve the desired texture.

The extrusion process can be customized to produce products with specific characteristics, such as expanded snacks or dense, chewy textures. This flexibility makes extrusion a valuable tool in modern food manufacturing.

Fermentation and Enzymatic Processes | Food Manufacturing Process

Fermentation and enzymatic processes are used to modify the chemical composition of food products, enhancing their flavor, texture, and nutritional value. Fermentation involves the action of microorganisms, such as bacteria or yeast, to break down ingredients.

Enzymatic processes, on the other hand, utilize enzymes to catalyze specific biochemical reactions. Both techniques are essential for producing a variety of fermented foods and beverages, such as yogurt, cheese, and beer.

Batch vs. Continuous Processing | Food Manufacturing Process

Food manufacturers can choose between batch and continuous processing methods for secondary processing operations. Batch processing involves producing a specific quantity of product in a single operation, whereas continuous processing allows for ongoing production without interruption.

The choice between batch and continuous processing depends on factors such as production volume, product complexity, and equipment capabilities. Continuous processing is often preferred for high-volume production, while batch processing offers flexibility for smaller batches or complex formulations.

Food Preservation Methods

Effective food preservation methods are crucial for the food industry, impacting both safety and product shelf life. Food preservation is critical for extending the shelf life of food products and ensuring their safety for consumption.

Thermal Preservation Techniques | Food Manufacturing Process

Thermal preservation involves using heat to kill microorganisms and extend the shelf life of food products. Techniques such as pasteurization and sterilization are widely used in the food industry.

Thermal Processing Methods include various techniques like canning, where food is heated to high temperatures to kill bacteria and other pathogens, and then sealed in airtight containers.

| Method | Description | Application |

|---|---|---|

| Low-Acid Canned Foods (LACF) | Thermal processing for low-acid foods to ensure safety | Canned vegetables, meats |

| Pasteurization | Heat treatment to reduce microbial load | Dairy products, juices |

| Sterilization | High-temperature treatment to eliminate all microbes | Canned goods, ready-to-eat meals |

Non-Thermal Preservation Methods | Food Manufacturing Process

Non-thermal preservation techniques are gaining popularity as they help preserve the nutritional and sensory qualities of food. High-Pressure Processing (HPP) is a notable example, where high pressure is used to inactivate harmful bacteria without heat.

High-Pressure Processing (HPP) is particularly effective for products like jams, juices, and guacamole, where maintaining flavor and texture is crucial.

Chemical Preservation Approaches | Food Manufacturing Process

Chemical preservation involves using additives to prevent spoilage and extend shelf life. Common chemical preservatives include sodium benzoate and potassium sorbate.

The choice of preservation method depends on the type of food product, its acidity, and the desired shelf life. A combination of preservation techniques is often used to achieve optimal results.

Specialized Food Manufacturing Processes

Different food products require unique manufacturing processes, highlighting the complexity of the food manufacturing industry. The production of various food categories, such as dairy products, meat and poultry, bakery and confectionery items, and beverages, involves specialized techniques and equipment.

Dairy Product Manufacturing | Food Manufacturing Process

Dairy product manufacturing involves processes such as pasteurization, homogenization, and fermentation. Pasteurization is critical for ensuring the safety of dairy products by eliminating harmful bacteria. Fermentation is used to create products like yogurt and cheese, where the action of beneficial bacteria is harnessed to develop flavor and texture.

A typical dairy processing plant might include equipment such as pasteurizers, separators, and packaging lines. The quality of the raw milk is paramount, and dairy manufacturers must adhere to strict quality control measures.

“The dairy industry is highly regulated, with a strong focus on safety and quality. Manufacturers must comply with regulations regarding the handling, processing, and storage of dairy products.”

| Process | Description | Equipment Used |

|---|---|---|

| Pasteurization | Heat treatment to kill harmful bacteria | Pasteurizers |

| Homogenization | Process to ensure fat molecules are evenly distributed | Homogenizers |

| Fermentation | Process using beneficial bacteria to create products like yogurt and cheese | Fermentation tanks |

Meat and Poultry Processing | Food Manufacturing Process

Meat and poultry processing involves a range of activities from slaughtering and evisceration to cutting, deboning, and packaging. Slaughtering and evisceration are initial steps where animals are humanely slaughtered, and internal organs are removed. Cutting and deboning involve preparing the meat for distribution and consumption.

Meat processing plants must adhere to strict sanitation and safety protocols to prevent contamination. Techniques such as modified atmosphere packaging (MAP) are used to extend the shelf life of meat products.

Bakery and Confectionery Production | Food Manufacturing Process

Bakery and confectionery production involves mixing, baking, and decorating. Mixing is a critical step where ingredients are combined in precise proportions. Baking involves cooking the products in ovens under controlled conditions.

Confectionery production often involves additional steps like tempering and molding for chocolate products. The quality of ingredients and precision in processing are crucial for the final product quality.

Beverage Manufacturing | Food Manufacturing Process

Beverage manufacturing encompasses a wide range of products, including soft drinks, juices, and bottled water. Formulation is a key step where ingredients are mixed according to recipes. Filling and packaging involve placing the beverage into containers, which are then sealed and labeled.

Beverage manufacturers must ensure that their products are free from contaminants and that packaging is appropriate for the product. Techniques like hot filling and aseptic filling are used to ensure product safety.

Food Processing Equipment and Technology

Food processing equipment and technology play a pivotal role in transforming raw ingredients into consumable products. The efficiency, safety, and quality of food products depend significantly on the type of equipment and technology used in the manufacturing process.

Essential Manufacturing Equipment

The food processing industry utilizes a wide range of equipment, from simple mechanical devices to complex automated systems. Essential manufacturing equipment includes:

- Mixers and Blenders: Used for combining ingredients in various food products.

- Cookers and Heat Exchangers: Employed for heating, cooking, and pasteurizing food products.

- Cutting and Slicing Equipment: Utilized for size reduction and portion control.

- Filtration Systems: Applied for clarifying and purifying food products.

Automation and Robotics in Food Processing

The integration of automation and robotics in food processing has revolutionized the industry by enhancing efficiency, reducing labor costs, and improving product consistency. Automated systems can perform tasks such as packaging, palletizing, and inspection with high precision.

Smart Manufacturing and Industry 4.0

Smart manufacturing and Industry 4.0 technologies are transforming food processing through the use of advanced data analytics, IoT devices, and real-time monitoring systems. These technologies enable predictive maintenance, optimized production scheduling, and improved supply chain management.

Equipment Maintenance and Sanitation

Regular equipment maintenance and sanitation are critical for ensuring the longevity of processing equipment and the safety of food products. Implementing effective maintenance schedules and sanitation protocols helps prevent contamination and equipment failure.

Food Safety Regulatory Framework in the U.S.

Ensuring food safety is a top priority in the United States, achieved through a robust regulatory framework. The U.S. food safety system is designed to protect consumers from foodborne illnesses by implementing various regulations and guidelines that food manufacturers must follow.

FDA Regulations and FSMA Requirements

The FDA plays a crucial role in regulating food safety through its oversight of food manufacturing facilities and enforcement of regulations. The Food Safety Modernization Act (FSMA) represents a significant shift in food safety regulation, focusing on preventing contamination rather than just responding to it.

Key aspects of FSMA include:

- Preventive Controls for Human Food

- Foreign Supplier Verification Programs

- Accredited Third-Party Certification

- Sanitary Transportation of Human and Animal Food

Current Good Manufacturing Practices (CGMP)

CGMP regulations are fundamental to ensuring that food is manufactured, processed, packed, or held under sanitary conditions. These practices cover a wide range of topics, including personnel hygiene, facility design, and equipment maintenance.

Preventive Controls for Human Food

Preventive controls are a critical component of the FSMA, requiring food facilities to implement controls to prevent hazards that could cause foodborne illness. This includes identifying potential hazards, implementing controls, and verifying their effectiveness.

HACCP vs. Preventive Controls | Food Manufacturing Process

Both HACCP (Hazard Analysis and Critical Control Points) and preventive controls are used to manage food safety risks, but they have different approaches. HACCP is a more traditional method that focuses on identifying and controlling hazards at critical points in the production process. Preventive controls, on the other hand, are a broader set of controls required by FSMA that encompass not just CCPs but also other measures to prevent hazards.

| Regulatory Component | Description | Key Requirements |

|---|---|---|

| FDA Regulations | Oversight of food manufacturing facilities | Compliance with CGMP, facility registration |

| FSMA Requirements | Preventive controls and verification | Preventive controls plan, supplier verification |

| CGMP | Sanitary conditions in food manufacturing | Personnel hygiene, facility design |

| Preventive Controls | Prevention of foodborne illness hazards | Hazard analysis, control implementation |

The U.S. food safety regulatory framework is comprehensive, involving multiple regulations and guidelines to ensure the safety of the food supply. Understanding and complying with these regulations is crucial for food manufacturers to avoid legal issues and, more importantly, to protect consumer health.

Implementing Food Safety Programs

The implementation of comprehensive food safety programs is essential for preventing contamination and ensuring compliance with regulations. These programs are multifaceted, involving several critical components that work together to safeguard the food supply.

Food Safety Plan Development | Food Manufacturing Process

A food safety plan is a detailed document outlining the procedures and protocols in place to manage food safety hazards. Developing a robust food safety plan involves identifying potential hazards, assessing risks, and implementing controls. This plan must be tailored to the specific operations of the food manufacturing facility, taking into account the types of products produced and the processes involved.

Effective food safety plans are built on the principles of Hazard Analysis and Critical Control Points (HACCP) or the Preventive Controls for Human Food rule under the Food Safety Modernization Act (FSMA). These frameworks provide a systematic approach to identifying and controlling hazards, ensuring that food products are safe for consumption.

Food Allergen Control Plans | Food Manufacturing Process

Food allergens pose a significant risk to consumer health, and managing this risk is a critical aspect of food safety programs. Food allergen control plans are designed to prevent cross-contamination with allergens and ensure that products containing allergens are properly labeled. These plans involve procedures for cleaning and sanitizing equipment, training staff on allergen handling, and validating the effectiveness of these measures.

Environmental Monitoring Programs

Environmental monitoring is a crucial element of food safety programs, particularly in ready-to-eat (RTE) food production environments. These programs involve regular testing for pathogens such as Listeria in the production environment to identify and eliminate potential sources of contamination before they affect the product.

Effective environmental monitoring programs require a thorough understanding of the production environment, including the identification of potential harborage sites for pathogens. This involves sampling and testing, as well as implementing corrective actions when necessary.

Sanitation Standard Operating Procedures (SSOPs)

Sanitation SSOPs are detailed procedures for cleaning and sanitizing equipment and facilities. These procedures are essential for maintaining a clean and safe production environment, preventing the buildup of pathogens and other contaminants.

Developing effective SSOPs involves understanding the types of soils and contaminants present in the facility, selecting appropriate cleaning and sanitizing agents, and training personnel on the proper execution of these procedures. Regular validation and verification of SSOPs are also critical to ensure their ongoing effectiveness.

Packaging and Labeling in Food Manufacturing

Packaging and labeling play a pivotal role in food manufacturing, safeguarding consumer health and facilitating informed purchasing decisions. The importance of these elements cannot be overstated, as they directly impact product safety, regulatory compliance, and consumer trust.

Packaging Materials and Technologies

The selection of appropriate packaging materials is critical in food manufacturing. Various materials such as glass, plastic, metal, and paper are used, each with its own set of advantages and limitations. For instance, aseptic packaging is widely used for liquid products, extending shelf life without refrigeration.

The development of new packaging technologies continues to evolve, with innovations like modified atmosphere packaging (MAP) and active packaging enhancing product freshness and safety. These technologies help in controlling the atmosphere around the product, thereby reducing spoilage and preserving quality.

Food Contact Substances and FDA Regulations

Food contact substances (FCS) are materials that come into contact with food during manufacturing, processing, or storage. The FDA regulates FCS to ensure they are safe for use. Manufacturers must comply with FDA guidelines to avoid contamination and ensure consumer safety.

“The FDA’s regulations on food contact substances are designed to protect public health by ensuring that materials used in food packaging do not adulterate food.”

— FDA Guidelines

Packaging Validation Requirements | Food Manufacturing Process

Packaging validation is a critical step in ensuring that food products remain safe and fresh throughout their shelf life. This involves testing packaging materials and designs to verify they meet the required standards. Validation processes include physical testing, such as leak testing and drop testing, to ensure packaging integrity.

| Validation Test | Purpose | Example |

|---|---|---|

| Leak Testing | To ensure packaging is sealed properly | Vacuum decay method |

| Drop Testing | To assess packaging durability | Drop from 1.5 meters |

Labeling Compliance and Standards

Labeling compliance is essential for food manufacturers to provide consumers with necessary information about the product, including ingredients, nutritional content, and allergen warnings. Compliance with FDA labeling regulations is mandatory, and manufacturers must stay updated on any changes to these regulations.

- Clear display of product name and ingredients

- Nutrition facts panel

- Allergen labeling

- Compliance with country-specific regulations

By prioritizing packaging and labeling, food manufacturers can ensure their products are safe, compliant with regulations, and appealing to consumers.

Quality Assurance and Process Control

Quality assurance and process control are fundamental components of food manufacturing, directly impacting product safety and quality. Ensuring that food products meet stringent quality and safety standards requires a multifaceted approach that encompasses various testing methods, statistical analysis, and meticulous documentation.

Quality Control Testing Methods

Quality control testing is a critical aspect of quality assurance in food manufacturing. It involves a range of methods to assess the physical, chemical, and microbiological characteristics of food products. Some common testing methods include:

- Microbiological testing: to detect pathogens and spoilage microorganisms

- Physical testing: to evaluate texture, appearance, and other physical attributes

- Chemical testing: to analyze the composition and detect contaminants

These testing methods help manufacturers identify potential issues early in the production process, enabling them to take corrective actions and prevent product recalls or safety hazards.

Statistical Process Control in Food Manufacturing

Statistical process control (SPC) is a methodology that uses statistical techniques to monitor and control processes in food manufacturing. SPC involves collecting data on key process parameters and analyzing it to detect trends, patterns, or anomalies. By implementing SPC, manufacturers can:

- Identify variations in the process that may impact product quality

- Take corrective actions to bring the process back under control

- Continuously improve the manufacturing process

As noted by a leading food safety expert, “Statistical process control is a powerful tool for ensuring the consistency and quality of food products.” Effective SPC requires a deep understanding of the manufacturing process and the ability to interpret data accurately.

“The goal of SPC is to make data-driven decisions that improve product quality and reduce waste.”

Sensory Evaluation Techniques

Sensory evaluation is another crucial aspect of quality assurance in food manufacturing. It involves assessing the sensory characteristics of food products, such as taste, smell, texture, and appearance. Trained sensory panels or expert evaluators use various techniques to evaluate the sensory attributes of products. This helps manufacturers to:

- Ensure that products meet consumer expectations

- Identify potential quality issues before products reach the market

- Develop new products that meet consumer preferences

Documentation and Record-Keeping

Accurate documentation and record-keeping are essential for effective quality assurance and process control. Manufacturers must maintain detailed records of:

- Quality control testing results

- Process control data

- Sensory evaluation findings

- Corrective actions taken

These records serve as evidence of compliance with regulatory requirements and industry standards. They also provide valuable insights for continuous improvement initiatives.

Distribution and Supply Chain Management

Distribution and supply chain management play a vital role in ensuring the safe delivery of food products. Effective management of these processes is crucial for maintaining product quality, ensuring regulatory compliance, and meeting customer demands.

Food Traceability Requirements (FSMA Rule 204)

The Food Safety Modernization Act (FSMA) Rule 204 requires food manufacturers to implement food traceability records. This regulation aims to improve the ability to identify and remove contaminated products from the market quickly.

- Maintain accurate records of food traceability

- Implement systems for tracking and tracing food products

- Ensure compliance with FSMA regulations

Sanitary Transportation of Food

Sanitary transportation practices are essential for preventing contamination during food transportation. This includes:

- Maintaining clean and sanitary vehicles

- Properly handling and storing food products during transport

- Training transportation personnel on sanitary practices

Cold Chain Management

Cold chain management is critical for perishable food products. It involves maintaining a consistent refrigerated temperature throughout the supply chain to prevent spoilage and contamination.

Key aspects of cold chain management include:

- Temperature monitoring and control

- Proper packaging and insulation

- Training personnel on cold chain management practices

Warehouse Management and Logistics

Efficient warehouse management and logistics are vital for ensuring the timely and safe delivery of food products. This includes:

- Implementing inventory management systems

- Maintaining a clean and organized warehouse environment

- Optimizing storage and retrieval processes

By focusing on these critical areas, food manufacturers can ensure a robust distribution and supply chain management system that maintains product quality and safety.

The Future of Food Manufacturing

The food manufacturing industry is continually evolving, driven by advances in technology, changing consumer preferences, and regulatory requirements. As we look to the future of food manufacturing, several key trends are expected to shape the industry, including the adoption of smart manufacturing technologies and a heightened focus on food safety innovations.

Food manufacturing trends indicate a shift towards more efficient and sustainable production methods, driven by the need to meet growing consumer demand for safe, high-quality food products. The integration of smart manufacturing in food production is expected to play a crucial role in this process, enabling manufacturers to optimize production processes, reduce waste, and improve product quality.

Leading food process equipment manufacturers are already investing in the development of new technologies and equipment designed to support these emerging trends. As the industry continues to evolve, it is likely that we will see further innovations in food manufacturing, driven by the need to meet changing consumer preferences and regulatory requirements.

FAQ

What is the food manufacturing process?

The food manufacturing process involves transforming raw materials into finished goods through various stages, including sourcing, processing, packaging, and distribution, while ensuring food safety and quality.

What are the primary processing techniques used in food manufacturing?

Primary processing techniques include mechanical, thermal, and chemical processing methods, such as grinding, cooking, and pasteurization, which are used to transform raw materials into intermediate products.

What is the role of process engineers in food manufacturing?

Process engineers design, develop, and implement food manufacturing processes, ensuring efficiency, safety, and quality, and optimizing production workflows.

What are critical control points in food production?

Critical control points are steps in the food manufacturing process where controls can be applied to prevent or minimize food safety hazards, such as contamination or spoilage.

What is the importance of supplier approval programs in food manufacturing?

Supplier approval programs ensure that raw materials are sourced from qualified suppliers who meet quality and safety standards, reducing the risk of contamination or adulteration.

What are the different types of food preservation methods?

Food preservation methods include thermal, non-thermal, and chemical preservation techniques, such as canning, freezing, and using preservatives, which help extend shelf life and maintain food safety.

What is the significance of food safety regulations in the U.S.?

Food safety regulations, such as FDA regulations and FSMA requirements, ensure that food manufacturers adhere to strict guidelines to prevent foodborne illnesses and maintain a safe food supply.

What is the role of HACCP plans in food safety?

HACCP (Hazard Analysis and Critical Control Points) plans are systematic approaches to identifying and controlling food safety hazards, ensuring that food manufacturers produce safe and compliant products.

What are the benefits of adopting automation and robotics in food processing?

Automation and robotics improve efficiency, reduce labor costs, and enhance product quality and consistency, while also improving food safety by minimizing human contact.

What is the importance of packaging validation in food manufacturing?

Packaging validation ensures that packaging materials and designs meet food safety and quality requirements, preventing contamination and spoilage during storage and transportation.

What is the significance of food traceability in the supply chain?

Food traceability enables the tracking of food products throughout the supply chain, facilitating quick identification and recall of contaminated or adulterated products, and improving overall food safety.

What are the emerging trends shaping the future of food manufacturing?

Emerging trends, such as smart manufacturing, Industry 4.0, and sustainable practices, are transforming the food manufacturing landscape, enabling greater efficiency, flexibility, and responsiveness to changing consumer demands.

Conclusion of: Food Manufacturing Process

Introduction: What the food manufacturing process covers

The food manufacturing process in the United States spans everything from sourcing raw agricultural inputs to distributing shelf-ready products under strict federal oversight. Most packaged foods fall under FDA’s Current Good Manufacturing Practice (CGMP) and Preventive Controls rules, while meat, poultry, and some egg products are overseen by USDA. This guide walks through the practical steps U.S. plants follow to turn ingredients into safe, high-quality finished goods—highlighting controls you should build into each stage of the food manufacturing process. FDA Preventive Controls for Human Food (FSMA)

Regulatory backbone: CGMPs shape the food manufacturing process

CGMPs are the everyday rules that underpin the food manufacturing process—governing people, plant design, sanitation, process controls, and records. They’re the baseline practices every facility must implement, even before hazard-specific preventive controls come into play. If you’re designing or auditing any part of the food manufacturing process, start by aligning with CGMP Subpart B and then layer on hazard analysis, monitoring, and verification. FDA overview: CGMPs (21 CFR Part 117)

Supplier approval: first gate in the food manufacturing process

A robust supplier program is a non-negotiable early step in the food manufacturing process. You’ll assess supplier risk, review COAs, set specifications, and verify that any hazards controlled before receipt are truly managed. For many plants, supply-chain-applied controls and approval criteria are documented as part of the Food Safety Plan, with ongoing verification such as audits or sampling. FDA: Preventive Controls & Supply-Chain Program

Receiving and incoming inspection

When ingredients arrive, the food manufacturing process requires checks for integrity, temperature (if perishable), labeling, pest evidence, and compliance with specs. CGMPs also require qualified personnel and hygienic handling to prevent contamination during unloading. Your receiving SOPs should spell out acceptance criteria, sealing/tamper checks, and “hold” procedures for nonconforming lots. eCFR: 21 CFR 117 Subpart B (CGMP)

Storage and inventory control

Proper storage—ambient, refrigerated, or frozen—is central to the food manufacturing process. Use FIFO/FEFO rotation, map temperature zones, and separate raw and ready-to-eat (RTE) ingredients to avoid cross-contamination. Basic food safety principles also apply: keep cold foods cold, prevent cross-contact, and maintain clean, dry spaces to minimize microbial growth. CDC: Four Steps to Food Safety

Formulation and allergen management

Formulation controls make the food manufacturing process repeatable and safe. U.S. labels must declare “major food allergens,” now including sesame as the ninth major allergen. Control points here include verified recipes, scaled batching, dedicated utensils, validated changeovers, and label verification to prevent undeclared allergens—one of the most common recall causes. FDA Guidance: Food Allergen Labeling (Edition 5)

Produce and water contact steps (where relevant)

If your food manufacturing process includes fresh produce steps (washing, trimming, minimal processing), integrate agricultural water quality and sanitation controls consistent with the Produce Safety Rule. Even in mixed facilities, attention to water source, sanitizer concentrations, and drip/dry zones reduces cross-contamination risks downstream. FDA: Produce Safety Rule (21 CFR Part 112)

Comminution, mixing, and emulsification

Grinding, mixing, and emulsifying introduce large surface areas and intense contact among ingredients—so this stage of the food manufacturing process needs tight sanitation frequency, foreign-material controls, and allergen changeover verification. Preventive controls should address foreseeable hazards, with monitoring, corrective actions, and verification documented in the Food Safety Plan. FDA Draft Guidance: Hazard Analysis & Preventive Controls

Thermal processing and lethality

For low-acid canned foods and acidified foods, specific federal rules govern the food manufacturing process, including scheduled processes, thermal validation, and filing/registration. Beyond canning, many foods rely on pasteurization or validated kill-steps to reduce pathogens to safe levels. Recordkeeping and process deviations must be handled per your plan. FDA: Low-Acid & Acidified Foods (21 CFR 113 & 114)

Nonthermal technologies (HPP, irradiation)

Some facilities incorporate nonthermal steps into the food manufacturing process, such as high-pressure processing (HPP) or irradiation, to achieve lethality while preserving quality. These interventions require scientific validation and regulatory compliance; irradiation permitted uses are codified in federal regulations, and HPP validations must demonstrate pathogen reduction without compromising safety elsewhere. FDA: Food Irradiation Overview

Environmental monitoring and control of Listeria in RTE areas

An environmental monitoring program (EMP) verifies that sanitation and zoning in the food manufacturing process keep pathogens—especially Listeria monocytogenes—out of RTE areas. Programs typically include traffic flow, hygienic zoning (raw vs. RTE), vector/swab sites, corrective actions, and trend analysis to prevent harborage. FDA Draft Guidance: Control of Listeria in RTE Foods

Hygienic design, upkeep, and facilities

Hygienically designed equipment and buildings support the food manufacturing process by making cleaning effective and preventing niches where moisture and residues persist. Coupled with preventive maintenance and documented inspections, plants can meet sanitation performance expectations and streamline cleaning time without sacrificing food safety. USDA FSIS: Sanitation Performance Standards Compliance Guide

Cleaning & sanitation (CIP/SIP) and SSOPs

Documented Sanitation Standard Operating Procedures (SSOPs) are the daily backbone of the food manufacturing process. Define what gets cleaned, how, by whom, how often, and how effectiveness is verified (ATP, visual, micro). CIP/SIP systems should be validated for soil loads and “worst-case” conditions, with pre-op inspections and post-sanitation swabbing built into routines. USDA FSIS: Sanitation SOPs Guidance

Allergen changeovers and label verification

Because undeclared allergens drive many recalls, this checkpoint in the food manufacturing process demands rigorous label control, physical or procedural segregation, validated cleaning between allergen runs, and documented label reviews. Sesame has been a major focus since 2023, and manufacturers must account for it in both processing and labeling steps. FDA: FASTER Act — Sesame as 9th Major Allergen

Packaging and food contact materials

Primary packaging must be safe and suitable for its intended use in the food manufacturing process. In the U.S., many food-contact substances are authorized through FDA’s Food Contact Notification (FCN) program or specific regulations. Packaging changes should trigger a regulatory review to confirm the material is cleared for the food type, use level, and temperature. FDA: How FDA Regulates Food-Contact Substances

Coding, traceability, and recall readiness

Effective lot coding and end-to-end traceability make the food manufacturing process more resilient when issues arise. FDA’s Food Traceability Rule sets additional recordkeeping for certain high-risk foods, while all FDA-regulated firms should maintain recall plans with defined roles, contact lists, and mock recall drills to verify speed and accuracy. FDA: Food Traceability Final Rule (FSMA 204)

Quality testing, verification, and release

Before release, the food manufacturing process typically includes finished-product checks (sensory, label, net weight, micro/chem as applicable) and review of critical records (monitoring, deviations, corrective actions). Where microbiological testing is used, validated methods and accredited labs or established in-house programs are key to defensible decisions. FDA: Bacteriological Analytical Manual (BAM)

Distribution and the sanitary transportation rule

The food manufacturing process doesn’t end at the dock. Shippers, loaders, carriers, and receivers must prevent contamination during transit by controlling temperatures, protecting against cross-contamination, and cleaning conveyances. Contracts and records should define responsibilities, including temperature monitoring and corrective actions. FDA: Sanitary Transportation Rule

Sustainability, waste, and by-product management

Modern plants build sustainability into the food manufacturing process—reducing water and energy use, diverting organic by-products, and minimizing landfill waste. EPA provides tools for preventing and diverting wasted food, along with resources on anaerobic digestion and composting for industrial generators. EPA: Sustainable Management of Food

Worker safety and training

People make the food manufacturing process work. Beyond food safety training, plants must protect workers from hazards such as chemicals (e.g., ammonia), machines, ergonomic stresses, and slips/falls. Align your EHS program with OSHA guidance and link it to your food safety culture—fatigued or unsafe teams make quality and safety errors. OSHA: Food Processing Industry

Digitalization and smart manufacturing

Industry 4.0 tools—real-time sensors, MES/SCADA, data lakes, and predictive maintenance—can streamline the food manufacturing process by improving OEE, cutting changeover time, and strengthening traceability. As you digitize, consider cybersecurity, interoperability, and measurement science so data actually improves decisions on the floor. NIST: Smart Manufacturing

Capability building for small and mid-size plants

Smaller processors can accelerate their food manufacturing process maturity with external help on food safety, quality systems, and operations. The NIST MEP National Network offers support—training, gap assessments, and implementation—to raise compliance and performance while keeping costs in check. NIST MEP: Food Industry Services

Recalls and continuous improvement

Even with strong controls, the food manufacturing process must be “recall-ready.” Map your recall strategy, reporting chains, and documentation in advance; conduct mock recalls and trace exercises; and close CAPAs quickly. FDA’s recall framework and guidance outline expectations, timelines, and effective communication practices. FDA Guidance: Initiation of Voluntary Recalls

Final thought

The most successful food manufacturing process is both compliant and competitive: CGMPs as the daily discipline, preventive controls as your risk engine, smart tech for speed and visibility, and a culture that treats quality and safety as everyone’s job. Use this guide as a blueprint, then tailor each control to your hazards, equipment, people, and brand promise. FDA: FSMA FAQs

Sources & References

- FDA — Preventive Controls for Human Food (21 CFR 117)

- eCFR — 21 CFR Part 117 Subpart B (CGMP)

- FDA Draft Guidance — Hazard Analysis & Preventive Controls

- FDA — Control of Listeria in RTE Foods (Draft)

- USDA FSIS — Sanitation Performance Standards Compliance Guide

- FDA — Food Allergen Labeling (Edition 5)

- FDA — FASTER Act (Sesame)

- FDA — Regulating Food-Contact Substances

- FDA — Bacteriological Analytical Manual (BAM)

- CDC — Four Steps to Food Safety

- NIST — Smart Manufacturing

- NIST MEP — Food Industry Services

- EPA — Sustainable Management of Food

- FDA — Initiation of Voluntary Recalls (21 CFR Part 7)

- FDA — FSMA FAQs