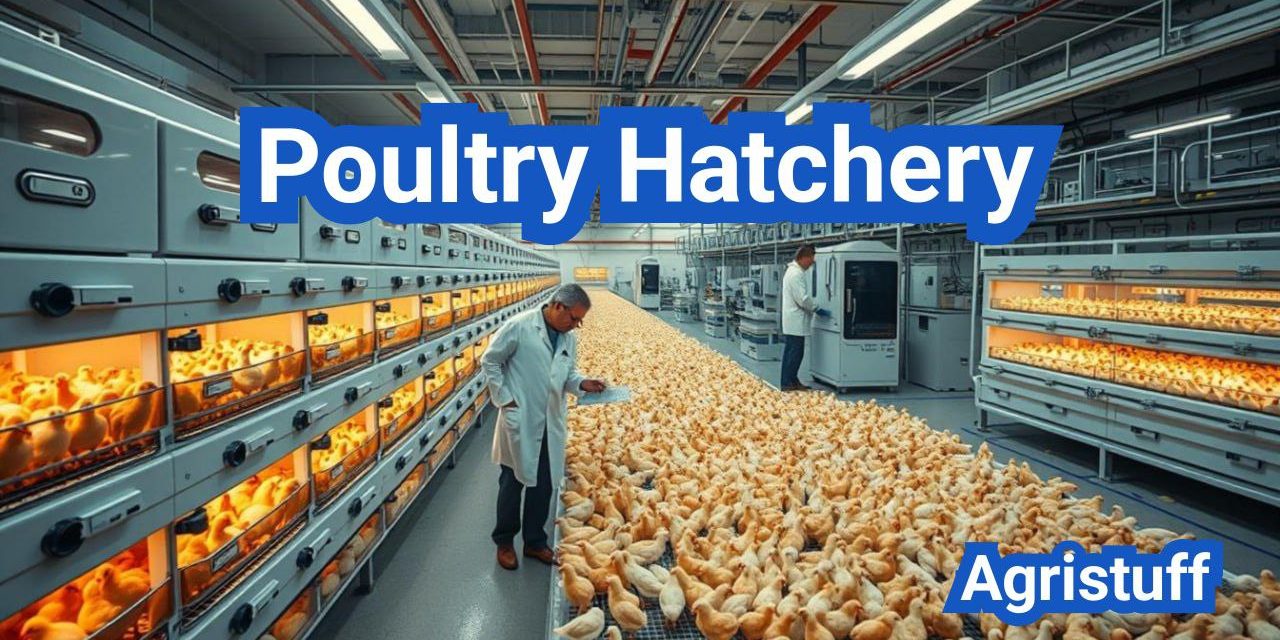

A poultry hatchery is a facility where eggs are incubated and hatched, playing a crucial role in the poultry farming industry.

The success of a poultry hatchery depends on various factors, including proper hatchery management, chick care, and equipment maintenance.

As highlighted in Robert Plamondon’s book “Success With Baby Chicks,” selecting the right hatchery and understanding chick care are essential for achieving success in poultry farming.

Key Takeaways

- Understanding the basics of poultry hatchery operations is crucial for success.

- Proper hatchery management is essential for healthy chick production.

- Poultry farming relies heavily on the quality of chicks produced in hatcheries.

- Effective chick care is vital for reducing mortality rates and promoting healthy growth.

- Selecting the right hatchery is a critical decision for poultry farmers.

Understanding Poultry Hatchery Fundamentals

Understanding the basics of poultry hatcheries is essential for anyone involved in poultry production, whether commercially or as a hobby. Poultry hatcheries are the backbone of the poultry industry, providing the chicks that will eventually become the chickens raised for meat or eggs.

What is a Poultry Hatchery?

A poultry hatchery is a specialized facility designed to incubate eggs and hatch chicks. It’s a critical step in the poultry production process, requiring precise conditions to ensure the health and viability of the chicks.

Types of Poultry Hatcheries

Poultry hatcheries can be categorized based on their scale and purpose. The main types include:

- Commercial Hatcheries: Large-scale operations that supply chicks to farms and producers.

- Backyard or Hobby Hatcheries: Smaller operations often run by individuals for personal use or local sales.

- Specialty Hatcheries: Focus on specific breeds or types of poultry, catering to niche markets.

| Hatchery Type | Scale | Purpose |

|---|---|---|

| Commercial | Large | Supply chicks to farms and producers |

| Backyard/Hobby | Small | Personal use or local sales |

| Specialty | Varies | Niche markets, specific breeds |

The Importance of Hatcheries in Poultry Production

Hatcheries play a crucial role in the poultry industry by providing healthy, high-quality chicks. The efficiency of a hatchery directly impacts the overall productivity and profitability of poultry farming. According to “Success With Baby Chicks,” understanding hatchery operations is key to success in poultry production.

The importance of hatcheries can be seen in their ability to:

- Control the quality of chicks through proper breeding and incubation practices.

- Supply chicks consistently, meeting the demands of the poultry industry.

- Implement biosecurity measures to protect against diseases.

In conclusion, poultry hatcheries are fundamental to the poultry industry, serving as the starting point for both commercial and backyard poultry production. Understanding the different types of hatcheries and their significance is crucial for anyone involved in the industry.

Planning Your Poultry Hatchery Business

Establishing a successful poultry hatchery business requires meticulous planning and research. A well-structured plan is crucial for navigating the complexities of the industry and ensuring long-term profitability.

Market Research and Business Planning

The first step in planning your poultry hatchery is to conduct thorough market research. This involves understanding the demand for poultry products in your region, identifying your target market, and analyzing your competitors. A comprehensive business plan should outline your production goals, marketing strategies, and financial projections.

Effective business planning also requires understanding the regulatory environment and obtaining necessary permits and licenses. It’s essential to stay updated on industry standards and best practices to ensure compliance and maintain a competitive edge.

Selecting Your Hatchery Focus

Deciding on the focus of your hatchery is a critical decision that will influence your operations and marketing strategies. You may choose to specialize in a particular breed or cater to a specific market segment, such as backyard poultry enthusiasts or commercial producers.

Consider factors like local demand, competition, and your expertise when selecting your hatchery’s focus. This decision will guide your decisions on breed selection, equipment, and marketing efforts.

Financial Considerations and Investment

Financial planning is a crucial aspect of establishing a poultry hatchery business. You need to estimate the initial investment required for setting up the hatchery, including costs for equipment, facilities, and initial operational expenses.

Ongoing expenses, such as feed, utilities, and labor, should also be factored into your financial plan. Developing a detailed financial projection will help you secure funding and make informed decisions about your business.

Commercial vs. Backyard Poultry Hatchery Operations

Commercial and backyard poultry hatcheries represent two distinct approaches to poultry production, differing in scale, complexity, and purpose. Understanding these differences is crucial for anyone looking to start or expand a poultry hatchery operation.

Large-Scale Commercial Hatchery Requirements

Large-scale commercial hatcheries are sophisticated operations that require significant investment in infrastructure, equipment, and personnel. Key requirements include:

- Advanced Incubation and Hatching Equipment: High-capacity incubators and hatchers that can handle thousands of eggs.

- Strict Biosecurity Measures: To prevent disease outbreaks that could devastate large flocks.

- Skilled Labor: Trained personnel to manage the complex process of incubation, hatching, and chick handling.

- Efficient Supply Chain Management: Reliable sources of fertile eggs and a distribution network for chicks.

Setting Up a Backyard Hatchery

Backyard hatcheries, on the other hand, offer a more accessible entry point for hobbyists or small-scale producers. Setting up a backyard hatchery involves:

- Selecting the Right Equipment: Smaller scale incubators and hatchers suitable for the available space.

- Source Fertile Eggs: Either from your own flock or a local supplier.

- Basic Biosecurity: While less complex than commercial operations, maintaining cleanliness and disease prevention is still crucial.

- Record Keeping: Tracking incubation conditions, hatch rates, and chick health.

Scaling Your Operation: From Hobby to Business

For those starting with a backyard hatchery, scaling up to a commercial operation is a significant step that requires careful planning. Considerations include:

- Market Research: Understanding demand for chicks and potential competition.

- Financial Planning: Securing funding for expansion, including equipment, facilities, and staffing.

- Regulatory Compliance: Ensuring that the expanded operation meets all relevant laws and regulations.

- Operational Efficiency: Streamlining processes to maintain quality and reduce costs as the operation grows.

Whether you’re operating a commercial or backyard poultry hatchery, the key to success lies in understanding the specific requirements and challenges of your operation. By carefully planning and managing your hatchery, you can achieve your production goals and contribute to the sustainable production of poultry.

Essential Poultry Hatchery Design and Layout

A well-designed poultry hatchery is crucial for the efficient production of healthy chicks. The design and layout of a hatchery play a significant role in ensuring the overall health and productivity of the chicks, as highlighted in “Success With Baby Chicks.”

Optimal Hatchery Layout Principles

The layout of a poultry hatchery should be designed to maximize efficiency and minimize the risk of contamination. This involves creating separate zones for different activities, such as incubation, hatching, and chick processing.

- Separation of high-risk and low-risk areas

- Efficient workflow and traffic control

- Adequate space for equipment and personnel

By implementing these principles, hatcheries can reduce the risk of disease transmission and improve overall productivity.

Space Requirements and Zoning

Adequate space is essential for the smooth operation of a poultry hatchery. The space requirements will vary depending on the size of the operation and the equipment used.

| Zone | Space Requirement | Key Considerations |

|---|---|---|

| Incubation | Sufficient for incubators and egg storage | Temperature control, humidity management |

| Hatching | Adequate for hatchers and chick handling | Ventilation, sanitation protocols |

| Chick Processing | Space for sorting, grading, and packaging | Temperature control, biosecurity measures |

Proper zoning helps in maintaining biosecurity and operational efficiency.

Environmental Control Systems

Environmental control is critical in a poultry hatchery, as it directly impacts chick health and hatchery efficiency. This includes temperature control, humidity management, and ventilation.

Key Components of Environmental Control Systems:

- Heating and cooling systems

- Humidity control systems

- Ventilation systems

By maintaining optimal environmental conditions, hatcheries can improve chick quality and reduce mortality rates.

Selecting the Right Hatchery Equipment

Poultry hatcheries rely on a range of specialized equipment to ensure the healthy development of chicks. The efficiency and productivity of a hatchery operation depend significantly on the quality and appropriateness of the equipment used.

Incubators and Hatchers

Incubators and hatchers are the heart of any poultry hatchery. Incubators provide a controlled environment for fertilized eggs during the initial stages of incubation, maintaining optimal temperature and humidity levels. Hatchers, on the other hand, are used in the final stages of incubation, providing a conducive environment for the eggs to hatch.

The choice between single-stage and multi-stage incubators depends on the hatchery’s production needs and management practices. Single-stage incubators are used for batches of eggs set at the same time, while multi-stage incubators can handle eggs at different stages of incubation.

| Equipment Type | Description | Key Features |

|---|---|---|

| Single-Stage Incubators | Used for batches of eggs set at the same time | Uniform temperature and humidity control |

| Multi-Stage Incubators | Can handle eggs at different stages of incubation | Flexible operation, heat production from older embryos helps maintain temperature |

Egg Handling Equipment

Egg handling equipment is crucial for the efficient and safe transfer of eggs within the hatchery. This includes egg candlers, egg sorters, and egg turning machines. Egg candling is a process used to check the fertility of eggs and monitor embryo development.

- Egg candlers: Used to check egg fertility and embryo development

- Egg sorters: Sort eggs based on size, weight, and quality

- Egg turning machines: Automate the process of turning eggs during incubation

Monitoring and Control Systems

Modern hatcheries utilize sophisticated monitoring and control systems to ensure optimal incubation conditions. These systems monitor temperature, humidity, and CO2 levels, and can automatically adjust conditions as necessary.

Monitoring systems provide real-time data on incubation conditions, allowing for quick intervention in case of any deviations from optimal conditions. This is crucial for maintaining high hatch rates and chick quality.

Automated Poultry Hatchery Technologies

Modern poultry hatcheries are increasingly adopting automation to improve hatch rates, reduce labor costs, and enhance chick quality. This shift towards automation is driven by the need for greater efficiency and consistency in hatchery operations.

Advantages of Automation

Automation in poultry hatcheries offers several key benefits. Increased efficiency is one of the primary advantages, as automated systems can handle tasks with precision and speed, reducing the workload on human staff. Additionally, automation helps in maintaining consistent conditions throughout the incubation and hatching process, which is crucial for optimal chick development.

The use of automated systems also leads to improved chick quality. By closely monitoring and controlling environmental conditions such as temperature and humidity, hatcheries can ensure that chicks are healthy and robust from the start. Furthermore, automation can help reduce the risk of human error, which is a significant factor in maintaining high standards of chick health.

Modern Automation Systems

Today’s hatchery automation systems are sophisticated and multifaceted. They include advanced incubators and hatchers that can be programmed to meet the specific needs of different breeds and stages of development. Monitoring and control systems are also integral, allowing for real-time tracking of critical parameters and immediate adjustments as needed.

Another crucial aspect of modern automation is the integration of data analytics. By collecting and analyzing data on hatchery performance, operators can identify areas for improvement and make informed decisions to optimize their operations.

Cost-Benefit Analysis

While the initial investment in automation technology can be significant, the long-term benefits often outweigh the costs. Reduced labor costs are a major advantage, as automated systems can perform many tasks that would otherwise require a large workforce. Additionally, the improvement in hatch rates and chick quality can lead to increased revenue through better sales of healthy chicks.

| Benefits | Description | Impact |

|---|---|---|

| Increased Efficiency | Automation handles tasks with precision and speed | Reduced labor costs |

| Consistent Conditions | Automated control of environmental factors | Improved chick quality |

| Data-Driven Decisions | Analytics provide insights into hatchery performance | Optimized operations |

Egg Selection and Handling Techniques

Selecting the right eggs and handling them properly is fundamental to hatchery success. The quality of eggs set in the incubator directly impacts hatchability, chick quality, and ultimately, the profitability of the hatchery operation.

Sourcing Fertilized Eggs

Sourcing high-quality fertilized eggs is the first step in ensuring a successful hatch. Breeder flocks should be well-managed, with attention to nutrition, health, and genetics to produce eggs with high hatchability potential. Factors such as breeder age, nutrition, and health status can significantly affect egg quality and fertility.

Egg Quality Assessment

Evaluating egg quality is crucial before incubation. Factors to consider include:

- Egg size and shape

- Shell cleanliness and integrity

- Absence of cracks or defects

“The quality of the egg is a critical factor in determining the success of the incubation process.”

Proper Egg Storage and Preparation

Proper storage and preparation of eggs before incubation are vital. Eggs should be stored in a cool, humid environment, and turned regularly to maintain the viability of the embryo. The storage conditions can significantly impact the hatchability of eggs, making it essential to monitor temperature and humidity levels closely.

By focusing on these critical aspects of egg selection and handling, hatcheries can improve their overall efficiency and productivity, leading to better outcomes for both the hatchery and its customers.

Mastering the Incubation Process

To ensure optimal hatchery performance, understanding and controlling the incubation process is essential. The incubation process is a complex series of events that requires precise conditions to result in healthy chicks.

Optimal Incubation Conditions

Maintaining optimal incubation conditions is critical for the development of embryos. The key factors include:

- Temperature: The ideal temperature for incubation is between 99°F and 100°F.

- Humidity: Relative humidity should be around 50-60% for the first 18 days and increased to 65-70% during the final days.

- Turning: Eggs should be turned regularly to prevent the embryo from sticking to the shell.

- Ventilation: Adequate ventilation is necessary to provide oxygen and remove carbon dioxide.

Incubation Stages and Monitoring

The incubation period can be divided into several stages, each with specific developmental milestones.

- Days 1-3: Fertilization and initial embryonic development.

- Days 4-7: Organogenesis and development of major organs.

- Days 8-14: Continued growth and development of feathers, beak, and claws.

- Days 15-21: Preparation for hatching, including positioning and absorption of yolk sac.

Monitoring these stages is crucial to identify any potential issues early on.

Troubleshooting Common Incubation Problems

Despite best efforts, issues can arise during incubation. Common problems include:

- Infertility: Caused by factors such as poor breeder health or inadequate mating ratios.

- Early Embryonic Mortality: Often due to genetic factors, improper incubation conditions, or disease.

- Late Embryonic Mortality: Can result from inadequate ventilation, temperature fluctuations, or contamination.

By understanding these potential issues, hatchery managers can take corrective actions to minimize losses.

The Chick Hatching Process Explained

Understanding the chick hatching process is essential for any poultry hatchery aiming for success. The chick hatching process involves several critical stages, from embryonic development to the moment the chick emerges, and continues with post-hatch care.

Stages of Embryonic Development

Embryonic development is the initial and most crucial stage of the chick hatching process. It begins with fertilization and continues until the chick is fully formed and ready to hatch. This development is highly sensitive to environmental conditions such as temperature and humidity.

Optimal incubation conditions are vital for the healthy development of the embryo. According to “Success With Baby Chicks,” maintaining a consistent temperature and humidity level is key to successful embryonic development.

Hatching Management Practices

Effective hatching management practices are critical for maximizing hatch rates and ensuring the health of the chicks. This includes monitoring the incubation environment, managing egg turning, and being prepared for the hatching process.

“The hatching process is a critical moment in poultry production, requiring careful management to ensure the health and viability of the chicks.”

Post-Hatch Care

Post-hatch care is equally important as the hatching process itself. It involves providing the newly hatched chicks with the right environment, nutrition, and care to ensure their survival and health.

As emphasized in poultry production guidelines, proper brooding conditions are essential for the chicks’ growth and development. This includes maintaining optimal temperature and humidity levels and ensuring access to food and water.

Effective Chick Brooding Practices

Successful chick brooding practices are essential for ensuring the health and well-being of young poultry. The brooding period is a critical phase in a chick’s life, requiring careful attention to detail to create a nurturing environment.

Brooding Environment Setup

Setting up the brooding environment involves several key factors. First, the brooder must be clean and disinfected before introducing the chicks. A well-ventilated area with adequate space is crucial. The recommended stocking density is about 0.5 to 1 square foot per chick, depending on the breed and size.

Essential elements for the brooding environment include:

- Adequate ventilation

- Proper lighting

- Comfortable bedding

- Easy access to food and water

Temperature and Humidity Control

Maintaining optimal temperature and humidity levels is vital during the brooding period. The temperature should be around 90-95°F (32-35°C) for the first week, gradually decreasing by 5°F (-3°C) each subsequent week until it reaches the ambient temperature.

| Week | Temperature (°F) | Humidity (%) |

|---|---|---|

| 1 | 90-95 | 50-60 |

| 2 | 85-90 | 50-60 |

| 3 | 80-85 | 50-60 |

As noted by “Success With Baby Chicks,”

“Monitoring temperature and humidity is crucial for the health of the chicks. Fluctuations can lead to stress and disease.”

Feeding and Watering Newly Hatched Chicks

Providing the right nutrition and ensuring access to clean water is fundamental. Chicks require a starter feed that is rich in protein and other essential nutrients. Fresh water should be available at all times, and feeders should be designed to prevent waste and contamination.

Key considerations for feeding and watering include:

- Using chick starter feed with at least 20% protein

- Ensuring feeders and waterers are clean and easily accessible

- Monitoring feed consumption and adjusting as necessary

By following these effective chick brooding practices, poultry producers can significantly improve the health and survival rates of their young chicks, setting the stage for a successful poultry operation.

Poultry Hatchery Management Best Practices

The key to a successful poultry hatchery lies in its management practices. Effective management ensures that the hatchery operates efficiently, maintaining high standards of quality and productivity.

Daily Operation Procedures

Daily operation procedures are the backbone of any successful hatchery. These procedures include egg handling, incubation monitoring, and chick processing. Ensuring that these tasks are performed correctly and consistently is crucial for maintaining high hatch rates and chick quality.

According to “Success With Baby Chicks,” effective hatchery management is key to success. This involves implementing standardized protocols for daily operations, such as checking incubator temperatures and humidity levels, monitoring egg hatches, and ensuring proper sanitation.

Record Keeping and Data Analysis

Accurate record keeping and data analysis are essential components of hatchery management. By maintaining detailed records of incubation conditions, hatch rates, and chick health, hatchery managers can identify areas for improvement and make informed decisions.

Data analysis can help in optimizing incubation conditions, reducing chick mortality, and improving overall hatchery efficiency. For instance, analyzing hatch rate data can reveal trends and patterns that may indicate issues with incubation conditions or equipment.

“The best way to predict the future is to create it.” – Abraham Lincoln. In the context of hatchery management, creating a successful future involves meticulous planning, precise execution, and continuous improvement.

Staff Training and Management

Staff training and management are critical to the success of a poultry hatchery. Well-trained staff can significantly impact the quality of chicks and the overall efficiency of the hatchery.

Training programs should cover all aspects of hatchery operations, including equipment operation, chick handling, and biosecurity protocols. Regular training updates and performance evaluations can help maintain high standards of operation.

Effective staff management involves not only training but also creating a positive work environment that encourages productivity and job satisfaction. This can lead to reduced staff turnover and improved overall performance.

Implementing a Robust Poultry Biosecurity Plan

Poultry biosecurity is a critical aspect that cannot be overlooked in hatchery management. A comprehensive biosecurity plan is essential for protecting the health of chicks and ensuring the overall success of the hatchery. As highlighted in “Success With Baby Chicks,” biosecurity plays a vital role in preventing disease outbreaks.

Critical Biosecurity Measures

Effective biosecurity involves several key measures. First, it’s crucial to control access to the hatchery. This includes:

- Limiting entry points to authorized personnel only

- Implementing a robust disinfection protocol for all entrances

- Using foot baths or other disinfection methods for personnel and visitors

Another critical aspect is the segregation of different areas within the hatchery. This can be achieved by:

- Designating specific areas for incubation, hatching, and chick rearing

- Ensuring that equipment and personnel do not move between these areas without proper sanitation

Disease Prevention Strategies

Disease prevention is a cornerstone of biosecurity. Strategies include:

- Regular monitoring of chick health and immediate response to any signs of illness

- Vaccination programs tailored to the specific needs of the flock

- Strict control over the introduction of new birds to the hatchery

A key component of disease prevention is maintaining a clean environment. This involves:

| Area | Cleaning Frequency | Disinfection Method |

|---|---|---|

| Incubation Room | Daily | UV Light and Chemical Disinfectant |

| Hatchery | After Each Hatch | Thorough Cleaning Followed by Disinfection |

| Brooding Area | Weekly | Removal of Soiled Bedding, Disinfection of Surfaces |

Visitor and Personnel Protocols

Visitors and personnel can inadvertently introduce diseases into the hatchery. To mitigate this risk:

- All visitors should be logged and their contact with the flock minimized

- Personnel should be trained in biosecurity protocols and adhere to strict hygiene practices

- Protective clothing, including gloves and masks, should be worn when handling chicks or entering sensitive areas

By implementing these measures, hatcheries can significantly reduce the risk of disease outbreaks, ensuring a healthier flock and a more successful operation.

Poultry Hatchery Sanitation Protocols

Poultry hatchery sanitation is a critical aspect that directly impacts the health and productivity of the chicks. Maintaining a clean and hygienic environment is essential for preventing disease outbreaks and ensuring the overall success of the hatchery operation.

Cleaning and Disinfection Procedures

Effective cleaning and disinfection are crucial for removing pathogens and contaminants from the hatchery environment. This involves:

- Regular sweeping and cleaning of floors and surfaces

- Disinfection of incubators, hatchers, and other equipment

- Proper disposal of waste materials

Disinfection procedures should be carried out using approved disinfectants, following the manufacturer’s instructions for concentration and contact time. It’s also important to ensure that all staff members are trained in proper cleaning and disinfection techniques.

Waste Management Systems

A well-designed waste management system is vital for maintaining a clean and healthy environment in the hatchery. This includes:

- Segregation of different types of waste (e.g., eggshells, chick waste, packaging materials)

- Proper storage of waste in designated areas

- Regular removal of waste from the premises

Implementing an effective waste management system not only improves sanitation but also helps in reducing environmental impact.

Sanitation Scheduling and Monitoring

To ensure that sanitation protocols are consistently followed, it’s essential to establish a sanitation schedule and monitoring system. This involves:

- Daily cleaning and disinfection routines

- Regular inspections to identify areas for improvement

- Record-keeping to track sanitation activities and outcomes

By maintaining a rigorous sanitation schedule and monitoring system, hatcheries can significantly reduce the risk of disease outbreaks and improve overall productivity.

Breed Selection for Your Hatchery

Breed selection plays a pivotal role in determining the viability and success of your poultry hatchery business. The choice of breed directly influences market demand, production costs, and overall profitability.

When considering breed selection, it’s essential to understand the different categories of poultry breeds and their specific characteristics. The primary categories include commercial meat birds, egg-laying breeds, and heritage or specialty breeds.

Commercial Meat Birds (Broilers and Cornish Cross)

Commercial meat birds, such as Broilers and Cornish Cross, are bred specifically for their rapid growth rate and high meat yield. These breeds are optimized for the poultry meat industry, offering:

- Fast growth rates, typically reaching market weight in 5-7 weeks

- High feed conversion ratios, making them cost-effective

- Consistent meat quality, appealing to large-scale producers and consumers

Breeds like the Cornish Cross are particularly popular in commercial settings due to their efficiency and the quality of meat they produce.

Egg-Laying Breeds and Hybrids

Egg-laying breeds are selected for their ability to produce a high volume of eggs. Popular layers include:

- Leghorns, known for their prolific egg production

- Hybrids like the Lohmann Brown, which offer a balance between egg production and hardiness

- Other breeds such as Rhode Island Reds, valued for their egg-laying capabilities and friendly disposition

These breeds are crucial for the egg production industry, with some hybrids capable of laying over 300 eggs per year.

Heritage and Specialty Breeds

Heritage and specialty breeds are gaining popularity due to their unique characteristics, such as:

- Diverse plumage and color patterns

- Foraging abilities, making them suitable for free-range systems

- Cultural or historical significance, appealing to niche markets

Examples include the Plymouth Rock, known for its friendly nature and dual-purpose use (eggs and meat), and the Silkie, valued for its unique appearance and brooding abilities.

Ultimately, the choice of breed should align with your business goals, market demand, and production system. By carefully selecting breeds that fit your hatchery’s niche, you can enhance your competitiveness and profitability in the poultry industry.

Building a Successful Poultry Hatchery

A successful hatchery is built on a foundation of careful planning, precise execution, and ongoing management. By understanding the fundamentals of poultry hatchery operations, selecting the right equipment, and implementing robust biosecurity measures, you can establish a thriving business.

Key hatchery success factors include maintaining optimal incubation conditions, managing chick brooding effectively, and ensuring rigorous sanitation protocols. By mastering these elements, you can achieve high hatch rates, healthy chicks, and a strong reputation in the market.

Resources like “Success With Baby” provide valuable guidance on chick care, supporting your journey to building a successful hatchery. By applying the knowledge and best practices outlined in this comprehensive guide, you’ll be well on your way to establishing a profitable and sustainable poultry hatchery business.

FAQ

What is a poultry hatchery?

A poultry hatchery is a facility where fertilized eggs are incubated and hatched to produce day-old chicks for the poultry industry.

What are the different types of poultry hatcheries?

Poultry hatcheries can be categorized into commercial, backyard, and specialty hatcheries, each serving different purposes and markets.

How do I start a poultry hatchery business?

To start a poultry hatchery business, you need to conduct market research, create a business plan, select a niche, and secure financing.

What are the key elements of poultry hatchery design and layout?

Optimal hatchery design includes proper zoning, environmental control systems, and sufficient space to ensure a healthy environment for chicks.

What equipment is necessary for a poultry hatchery?

Essential equipment includes incubators, hatchers, egg handling equipment, and monitoring and control systems to manage the incubation and hatching process.

How can automation benefit a poultry hatchery?

Automation can improve efficiency, reduce labor costs, and enhance chick quality by providing precise control over incubation and hatching conditions.

What are the best practices for egg selection and handling?

Best practices include sourcing high-quality fertilized eggs, assessing egg quality, and proper storage and preparation to ensure optimal hatchability.

What are the optimal conditions for incubation?

Optimal incubation conditions include precise temperature, humidity, and ventilation control to support embryonic development.

How do I manage the chick hatching process?

Effective hatching management involves monitoring the hatching process, ensuring proper chick handling, and providing post-hatch care.

What are the key factors in chick brooding?

Key factors include setting up a suitable brooding environment, controlling temperature and humidity, and providing proper feeding and watering for newly hatched chicks.

Why is biosecurity important in a poultry hatchery?

Biosecurity is crucial to prevent disease outbreaks, protect chick health, and ensure the overall success of the hatchery.

How do I select the right breed for my hatchery?

Breed selection depends on market demand, production goals, and the characteristics of different breeds, including commercial meat birds, egg-laying breeds, and heritage or specialty breeds.

What are the sanitation protocols for poultry hatcheries?

Sanitation protocols include regular cleaning and disinfection, effective waste management, and scheduled monitoring to maintain a clean and healthy environment.

How can I ensure the success of my poultry hatchery?

Success can be achieved by following best practices in hatchery management, maintaining high biosecurity standards, and continually monitoring and improving operations.

Conclusion of: Poultry Hatchery

A poultry hatchery plays a pivotal role in the poultry industry, serving as the starting point for meat and egg production. Whether you’re a small-scale farmer or managing a commercial operation, understanding how to establish and maintain a poultry hatchery is essential for long-term success. In the USA, the poultry hatchery business continues to thrive, making it an attractive opportunity for agricultural entrepreneurs. Learn more about the poultry industry’s growth from the U.S. Poultry & Egg Association.

Understanding a Poultry Hatchery

A poultry hatchery is a facility designed to incubate and hatch fertile eggs into healthy chicks. Every poultry hatchery must maintain strict environmental control, biosecurity, and record-keeping to ensure optimal hatchability and chick quality. For detailed guidelines, refer to the Cobb Hatchery Management Guide .

Selecting Fertile Eggs for a Poultry Hatchery

Egg selection is one of the first critical steps in any poultry hatchery. Eggs used in a poultry hatchery must be clean, uniform in size, and collected from healthy breeding stock. Proper egg selection directly affects hatch rates and chick health. The Mississippi State University Extension provides insights on egg quality standards .

Egg Storage Practices in a Poultry Hatchery

In a poultry hatchery, storing eggs correctly before incubation is essential to maintain embryo viability. Eggs should be stored at 55–65°F with moderate humidity and positioned at a 45-degree angle. Storage beyond 7 days may negatively affect hatch rates in a poultry hatchery. The USDA’s Agricultural Marketing Service offers storage best practices for hatcheries.

Incubation Management in a Poultry Hatchery

Incubation is the core of any poultry hatchery. The incubator must maintain a stable temperature of around 99.5°F and humidity between 40% and 50% during the first 18 days. Regular monitoring is vital to ensure successful development in a poultry hatchery. Explore incubation techniques from the University of Georgia Extension.

Egg Turning Protocol in a Poultry Hatchery

Egg turning is crucial in a poultry hatchery to prevent embryo adhesion and encourage healthy development. Automated systems in a poultry hatchery typically turn eggs hourly until the 18th day of incubation. For technical details, see the Poultry Science Association’s research.

Transferring to Hatchers in a Poultry Hatchery

On day 18, eggs are moved from the incubator to the hatcher in the poultry hatchery. The hatcher provides slightly cooler temperatures and higher humidity to support the final stage of chick development and successful hatching. The Iowa State University Poultry Hub covers hatcher management .

Monitoring Hatch Conditions in a Poultry Hatchery

Consistent monitoring of hatchers is essential in every poultry hatchery. Accurate temperature, humidity, and airflow management ensure high hatchability and strong chick output. The National Poultry Improvement Plan (NPIP) outlines best practices for hatch monitoring .

Post-Hatch Care in a Poultry Hatchery

Immediately after hatching, chicks require care within the poultry hatchery before moving to brooders. Proper ventilation, warmth, clean water, and starter feed are essential to promote strong early development. The American Pastured Poultry Producers Association (APPPA) provides chick-care guidelines.

Sanitation in a Poultry Hatchery

Cleanliness is non-negotiable in any poultry hatchery. Equipment, floors, and walls must be disinfected regularly to prevent bacterial and viral outbreaks. A poultry hatchery with strict sanitation protocols will have higher success rates. The CDC’s Biosecurity Guidelines are a key resource.

Biosecurity in a Poultry Hatchery

Biosecurity is a core principle in poultry hatchery management. Limiting access, controlling movement, using protective gear, and disinfecting vehicles are all necessary actions to prevent disease transmission within a poultry hatchery. Learn more from the USDA’s Animal and Plant Health Inspection Service (APHIS).

Personnel Training in a Poultry Hatchery

Staff in a poultry hatchery must be well-trained in handling eggs, operating equipment, and managing biosecurity procedures. Proper training helps maintain consistent standards and reduces the risk of human error in a poultry hatchery. The National Agricultural Library offers training materials.

Record-Keeping in a Poultry Hatchery

Maintaining comprehensive records is vital in a poultry hatchery. Tracking incubation times, hatch rates, egg origins, and chick quality helps improve decision-making and productivity in a poultry hatchery. The Farm Service Agency (FSA) provides record-keeping templates.

Technology and Automation in a Poultry Hatchery

Modern poultry hatchery operations benefit from automation and advanced technologies. Automated incubators, environmental sensors, and hatchery software enhance accuracy and reduce manual labor in a poultry hatchery. Discover innovations from AgriFarming.

Regulatory Compliance for a Poultry Hatchery

Running a poultry hatchery in the USA requires adherence to local and federal regulations. These include USDA standards, animal welfare rules, and environmental guidelines to ensure a legally compliant poultry hatchery. Review the FDA’s Egg Safety Rule.

Marketing Strategies for a Poultry Hatchery

A poultry hatchery must also focus on marketing. Building relationships with local farmers, participating in agricultural events, and establishing an online presence can attract buyers and grow the poultry hatchery’s reputation. The Small Business Administration (SBA) offers marketing tips .

Scaling a Poultry Hatchery Business

As demand increases, scaling your poultry hatchery becomes a logical next step. Introducing new breeds, expanding hatchery capacity, or adding additional locations can help grow the poultry hatchery business without compromising quality. The Penn State Extension discusses scaling strategies.

Final Thought

A well-run poultry hatchery forms the backbone of successful poultry production. By following best practices and maintaining high standards, anyone can operate a poultry hatchery that meets demand, ensures quality, and thrives in the U.S. agricultural landscape. For further reading, visit the Poultry Hub.