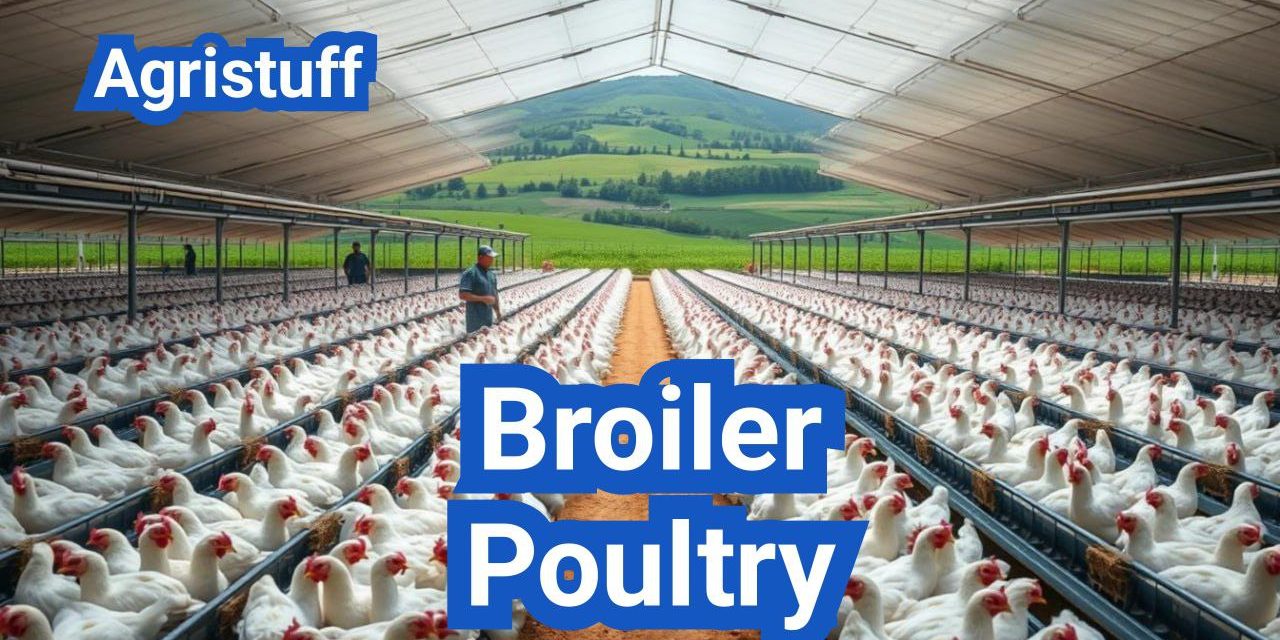

The broiler poultry business is a lucrative venture that involves raising chickens specifically bred for meat production. With the right strategies, it can be a highly profitable endeavor.

Efficient methods are crucial to maximizing profits in broiler chicken farming. By understanding the basics of this business, farmers can optimize their operations and improve their bottom line.

Key Takeaways

- Efficient methods are crucial for maximizing profits in broiler poultry farming.

- Understanding the basics of broiler chicken farming is essential for success.

- Optimizing operations can significantly improve profitability.

- Broiler poultry business requires careful planning and management.

- Maximizing profits involves adopting the right strategies and techniques.

Understanding the Broiler Poultry Industry

Understanding the dynamics of the broiler poultry industry is essential for farmers, investors, and consumers alike. The industry’s complexity and its significant contribution to the global food supply chain make it a vital sector to comprehend.

The Economic Importance of Broiler Production

Broiler production is a substantial contributor to the US economy, with the poultry sector being one of the largest in the world. The industry generates employment opportunities, stimulates economic growth, and provides a source of affordable protein for consumers. According to recent data, the US poultry sector is a significant player in the global market, with broiler production being a major component.

The economic importance of broiler production extends beyond the farm gate, influencing various sectors such as feed production, processing, and distribution. The industry’s impact on the economy is multifaceted, making it a crucial area of study for those involved in or affected by the sector.

Current Market Trends in the US Poultry Sector

The US poultry sector is subject to various market trends that influence the profitability and sustainability of broiler production. Current trends include the increasing demand for organic and specialty poultry products, driven by consumer preferences for healthier and more sustainably produced food options.

Another significant trend is the adoption of advanced technologies in broiler production, such as precision livestock monitoring systems and automated feeding and watering systems. These technologies enhance efficiency, reduce costs, and improve the overall welfare of the birds.

Comparing Broilers to Other Poultry Operations

Broiler production differs from other poultry operations, such as layer production or turkey farming, in several key aspects. Broilers are raised specifically for meat production, whereas layers are kept for egg production. The production cycles, management practices, and market dynamics vary significantly between these different types of poultry operations.

Understanding these differences is crucial for farmers and investors looking to enter or expand within the poultry sector. By comparing broilers to other poultry operations, stakeholders can make informed decisions about their investments and management strategies.

Getting Started with Broiler Poultry Farming

Starting a successful broiler farm involves careful planning, including understanding the essential requirements and legal considerations. Broiler poultry farming is a significant business venture that requires a thorough grasp of the initial setup and ongoing management practices.

Essential Requirements for a Broiler Farm

To establish a thriving broiler farm, several key elements must be in place. These include:

- Suitable Land and Location: The farm should be located in an area zoned for agricultural use, with adequate space for the broiler houses and waste management.

- Broiler Houses: Well-designed houses that provide a controlled environment for the chickens, including ventilation, temperature control, and lighting.

- Equipment: Feeders, drinkers, heating systems, and ventilation equipment are crucial for the health and growth of the broilers.

- Breeder Chickens or Chicks: Procuring high-quality chicks or breeder chickens from reputable suppliers is vital.

- Feed and Nutrition: A well-formulated feed that meets the nutritional needs of the broilers at different stages of growth.

Legal Considerations and Permits | Broiler Poultry

Compliance with legal requirements is a critical aspect of starting and operating a broiler farm. This includes:

- Obtaining necessary permits and licenses from local authorities.

- Compliance with environmental regulations, including waste management and pollution control.

- Adhering to animal welfare standards and biosecurity protocols.

- Registering the farm with relevant agricultural departments.

The specific legal considerations can vary by state and even by local jurisdictions, so it’s essential to consult with local authorities and agricultural experts.

Scale Options: From Backyard to Commercial Operations | Broiler Poultry

Broiler farming can be undertaken at various scales, from small backyard operations to large commercial farms. The scale of operation will significantly influence the initial investment, management practices, and potential returns.

| Scale of Operation | Initial Investment | Management Complexity | Potential Returns |

|---|---|---|---|

| Backyard | Low | Low | Limited |

| Small Commercial | Moderate | Moderate | Moderate |

| Large Commercial | High | High | High |

Understanding these factors is crucial for deciding the scale of operation that best suits your resources and goals.

Selecting the Right Broiler Chicken Breeds

Selecting a suitable broiler chicken breed is essential for achieving optimal growth rates and meat quality. The choice of breed can significantly impact the overall efficiency and profitability of the farm.

Commercial Broiler Varieties | Broiler Poultry

Commercial broiler varieties are bred specifically for their fast growth rate, efficient feed conversion, and high meat yield. Cornish Cross is one of the most popular commercial broiler breeds, known for its rapid growth and large breast size. Other notable commercial breeds include Ross 308 and Cobb 500, which are also recognized for their performance and meat quality.

The characteristics of these breeds make them well-suited for large-scale commercial operations. Here is a comparison of some key features:

| Breed | Growth Rate | Feed Conversion Ratio (FCR) | Average Market Weight |

|---|---|---|---|

| Cornish Cross | Fast | 1.7-1.8 | 2.5-3 kg |

| Ross 308 | Fast | 1.6-1.7 | 2.3-2.8 kg |

| Cobb 500 | Fast | 1.6-1.7 | 2.3-2.7 kg |

Alternative and Heritage Meat Breeds | Broiler Poultry

While commercial broiler breeds dominate the industry, alternative and heritage meat breeds are gaining popularity for their unique characteristics and potential to cater to niche markets. Heritage breeds are known for their slower growth rate compared to commercial broilers, but they offer superior flavor and texture, appealing to consumers looking for alternative poultry products.

Some examples of heritage breeds include Plymouth Rock, Jersey Giant, and Freedom Ranger. These breeds may not achieve the same level of efficiency as commercial broilers but provide a distinct product that can command a premium price in the market.

Understanding the differences between commercial and heritage breeds allows farmers to make informed decisions based on their production goals and target markets. Whether focusing on efficiency and volume or on quality and niche marketing, selecting the right broiler chicken breed is crucial for the success of the farm.

Broiler Poultry House Design and Setup

Broiler poultry house design plays a pivotal role in determining the overall efficiency and profitability of a poultry farm. A well-designed broiler house is essential for maintaining the health and productivity of the chickens.

Optimal Housing Systems for Different Scales | Broiler Poultry

The choice of housing system depends on the scale of the operation. For small-scale farms, simple open-sided houses may suffice, while large commercial operations often require more sophisticated, climate-controlled facilities.

Open-sided houses are suitable for smaller operations and are typically less expensive to construct. However, they offer less control over environmental conditions.

Climate-controlled houses, on the other hand, provide a more stable environment, which can lead to better growth rates and feed efficiency.

Environmental Control Systems | Broiler Poultry

Effective environmental control is critical in broiler production. This includes systems for ventilation, heating, and cooling to maintain optimal temperature and humidity levels.

- Ventilation systems help remove moisture and reduce the concentration of harmful gases.

- Heating systems are crucial during the brooding phase to maintain the required temperature.

- Cooling systems, such as evaporative cooling pads, help mitigate heat stress during warmer months.

Space Requirements and Stocking Density | Broiler Poultry

Adequate space is essential for the welfare of broiler chickens. Overcrowding can lead to stress, disease, and reduced growth rates.

The optimal stocking density depends on various factors, including the breed, age, and weight of the birds, as well as the housing system.

Equipment Selection and Layout | Broiler Poultry

The selection and layout of equipment within the broiler house can significantly impact the efficiency of the operation.

Key equipment includes feeders, drinkers, and ventilation systems. The layout should facilitate easy access for both the birds and the farm staff.

| Equipment | Considerations |

|---|---|

| Feeders | Easy access, adequate capacity, and adjustable height |

| Drinkers | Cleanliness, accessibility, and sufficient supply |

| Ventilation Systems | Effective air exchange, noise reduction, and energy efficiency |

Broiler Poultry Feed and Nutrition Management

Nutrition plays a vital role in broiler production, influencing both the health of the birds and the profitability of the operation. Effective feed management is crucial for achieving optimal growth rates, improving feed efficiency, and reducing production costs.

Understanding the Three-Phase Feeding Program

A three-phase feeding program is a common practice in broiler poultry farming, designed to meet the nutritional needs of chickens at different stages of their growth. This typically includes a starter phase, a grower phase, and a finisher phase. Each phase is formulated to provide the necessary nutrients for optimal growth and development.

The starter phase, usually from day 1 to 10, focuses on providing high-protein feed to support early growth. The grower phase, from around day 11 to 24, continues with a balanced diet that supports rapid growth. The finisher phase, from day 25 to market, adjusts the feed formulation to prepare the birds for market, often with a focus on optimizing feed conversion and reducing costs.

Feed Formulation for Maximum Growth | Broiler Poultry

Feed formulation is a critical aspect of broiler nutrition, requiring a balance of proteins, carbohydrates, fats, vitamins, and minerals. The goal is to provide a diet that supports maximum growth while minimizing waste and reducing the environmental impact.

Formulating feed involves considering the nutritional requirements of the broilers at different stages, the availability and cost of ingredients, and the need to maintain feed quality. Precision in feed formulation can significantly impact the overall efficiency and profitability of the broiler operation.

Calculating Feed Costs and Efficiency | Broiler Poultry

Feed costs represent a significant portion of the total costs in broiler production. Calculating feed costs and efficiency involves monitoring the amount of feed consumed by the birds and comparing it to their weight gain. The Feed Conversion Ratio (FCR) is a key metric used to evaluate feed efficiency.

Improving FCR through better feed formulation and management practices can lead to substantial cost savings. Farmers can achieve this by optimizing feed formulations, reducing feed waste, and ensuring that the feeding program is well-aligned with the growth stage of the birds.

Alternative and Organic Feed Options | Broiler Poultry

There is growing interest in alternative and organic feed options for broiler production, driven by consumer demand for more sustainably produced poultry products. Alternative feeds can include non-traditional ingredients such as insects or algae, while organic feeds must adhere to strict organic production standards.

Adopting alternative or organic feed options can provide a market premium and appeal to environmentally conscious consumers. However, it’s essential to carefully evaluate the nutritional content, cost, and availability of these alternatives to ensure they meet the needs of the broiler operation.

Optimizing Feed Conversion Ratio in Broilers

Achieving an optimal feed conversion ratio is essential for maximizing profits in the competitive broiler chicken industry. The feed conversion ratio (FCR) is a critical metric that measures the efficiency with which broilers convert feed into body weight.

Understanding FCR and Its Impact on Profitability | Broiler Poultry

The FCR is calculated by dividing the total amount of feed consumed by the total weight gained by the broilers. A lower FCR indicates better feed efficiency, which directly translates to lower production costs and higher profitability for farmers. Understanding and optimizing FCR is crucial for maintaining a competitive edge in the broiler market.

Nutritional Strategies to Improve FCR | Broiler Poultry

Nutritional strategies play a vital role in optimizing FCR. Formulating diets that meet the specific nutritional needs of broilers at different stages of their growth cycle is essential. This includes ensuring adequate protein, energy, and amino acid levels. Additionally, using feed additives such as enzymes and probiotics can enhance nutrient absorption and gut health, thereby improving FCR.

Environmental Factors Affecting Feed Conversionv | Broiler Poultry

Environmental factors significantly impact FCR in broilers. Maintaining optimal temperature and humidity levels within the poultry house is crucial, as extreme conditions can stress the birds and reduce feed efficiency. Proper ventilation and litter management also contribute to a healthy environment that supports better FCR.

Monitoring and Benchmarking FCR Performance | Broiler Poultry

Regular monitoring and benchmarking of FCR performance are essential for identifying areas of improvement. Farmers should track feed consumption and weight gain regularly and compare their FCR against industry benchmarks. This data-driven approach enables farmers to make informed decisions and implement targeted strategies to optimize their FCR.

Day-to-Day Management of Broiler Chickens

The success of a broiler chicken operation hinges on diligent daily management practices. Effective day-to-day management ensures the health, welfare, and productivity of the birds, ultimately impacting the profitability of the business.

The Broiler Growth Cycle from Day 1 to Market | Broiler Poultry

Understanding the growth cycle of broiler chickens is fundamental to their management. Broilers typically reach market weight in about 5-7 weeks, during which they go through various growth phases. Each phase has specific nutritional and environmental requirements that must be met to optimize growth and health.

The growth cycle can be divided into three main phases: starter, grower, and finisher. The starter phase (Day 1-10) focuses on providing optimal nutrition for young chicks. The grower phase (Day 11-24) involves transitioning to a grower feed and adjusting environmental conditions as needed. The finisher phase (Day 25 to market) prepares the birds for market, with a focus on efficient feed conversion and weight gain.

Daily Care Routines and Checklists | Broiler Poultry

Daily care routines are critical for maintaining the health and productivity of broiler chickens. Farmers should follow a structured checklist that includes monitoring feed and water availability, checking for signs of illness or stress, and ensuring the poultry house environment is within optimal temperature and humidity ranges.

- Check feed and water systems daily to ensure they are functioning correctly.

- Monitor bird health, looking for signs of disease or stress.

- Maintain optimal environmental conditions within the poultry house.

- Record daily observations and actions for future reference.

Monitoring Growth and Development | Broiler Poultry

Regular monitoring of growth and development is essential to identify any issues early and make necessary adjustments. This involves weighing birds regularly to track their growth rate and comparing it against breed standards or previous flocks.

Growth monitoring helps in early detection of health issues and allows for timely intervention. It also aids in optimizing feed formulations and management practices to achieve better performance.

Record Keeping Systems for Performance Tracking

Maintaining accurate records is vital for tracking the performance of broiler chickens over time. Record keeping systems should include data on feed consumption, growth rates, mortality, and any health interventions.

Effective record keeping enables farmers to analyze their operations, identify areas for improvement, and make informed decisions. It also helps in demonstrating compliance with regulatory requirements and industry standards.

Broiler Chick Brooding Techniques

Broiler chick brooding is a critical phase that requires precise management techniques. The first few weeks of a broiler chick’s life are crucial for determining its overall health, growth rate, and final market weight. Effective brooding practices lay the foundation for a successful broiler production cycle.

Preparing for Day-Old Chicks Arrival | Broiler Poultry

Before the arrival of day-old chicks, it’s essential to ensure that the brooding area is clean, disinfected, and well-prepared. This includes setting up brooders, feeders, and waterers, as well as checking the heating and ventilation systems.

Temperature and Humidity Control | Broiler Poultry

Temperature and humidity control are vital during the brooding phase. The ideal temperature for day-old chicks is around 92°F to 95°F, gradually decreasing as the chicks grow. Maintaining the right humidity levels helps prevent dehydration and promotes healthy growth.

First Week Management Practices | Broiler Poultry

The first week is critical for broiler chick development. Practices such as monitoring chick behavior, ensuring access to feed and water, and maintaining optimal environmental conditions are crucial. Regular checks on temperature, humidity, and chick health help identify any issues early on.

Transitioning from Brooding to Grow-out | Broiler Poultry

As chicks grow, they are gradually transitioned from the brooding area to the grow-out phase. This involves adjusting their environment, diet, and management practices to support continued growth and development.

| Brooding Practice | First Week | Second Week | Third Week |

|---|---|---|---|

| Temperature (°F) | 92-95 | 85-90 | 75-80 |

| Humidity (%) | 60-70 | 50-60 | 50 |

| Feeding Program | Starter Feed | Starter Feed | Grower Feed |

Poultry Biosecurity Protocols

Implementing robust poultry biosecurity protocols is crucial for the success of broiler chicken farming operations. Biosecurity measures are designed to protect poultry flocks from disease outbreaks, which can have devastating effects on farm productivity and profitability.

Creating a Comprehensive Biosecurity Planv | Broiler Poultry

A comprehensive biosecurity plan is the foundation of any successful poultry farming operation. It involves identifying potential disease risks and implementing strategies to mitigate these risks. Key elements of a biosecurity plan include:

- Access control measures to restrict entry to the farm

- Sanitation and disinfection protocols for equipment and personnel

- Monitoring and surveillance systems to detect early signs of disease

- Training programs for farm staff on biosecurity procedures

Disease Prevention Strategies | Broiler Poultry

Disease prevention is a critical aspect of poultry biosecurity. Effective strategies include:

- Implementing vaccination programs tailored to the specific disease risks in your area

- Maintaining strict hygiene practices, including regular cleaning and disinfection of facilities

- Controlling pests and rodents that can transmit diseases to poultry

Disease Prevention Measures are crucial for maintaining a healthy flock. The table below outlines some common disease prevention strategies and their benefits:

| Disease Prevention Strategy | Benefits |

|---|---|

| Vaccination Programs | Reduces the risk of specific diseases, improving flock health and reducing mortality rates |

| Strict Hygiene Practices | Minimizes the risk of disease transmission between flocks and reduces the need for antibiotics |

| Pest Control Measures | Reduces the risk of disease transmission through vectors like rodents and flies |

Visitor and Personnel Management | Broiler Poultry

Visitor and personnel management is a critical component of biosecurity. Farms should implement strict protocols for visitors and staff, including:

- Requiring the use of personal protective equipment (PPE) such as coveralls, gloves, and masks

- Implementing sign-in and sign-out procedures to track who is on the farm

- Limiting access to sensitive areas of the farm

Cleaning and Disinfection Procedures | Broiler Poultry

Effective cleaning and disinfection are essential for maintaining a biosecure environment. Procedures should include:

- Removing all organic material from surfaces before disinfection

- Using approved disinfectants at the correct concentration

- Ensuring all surfaces are exposed to the disinfectant for the recommended contact time

By implementing these poultry biosecurity protocols, farmers can significantly reduce the risk of disease outbreaks and maintain a healthy, productive flock.

Health Management in Broiler Poultry

A well-structured health management plan is vital for broiler producers to ensure the health and productivity of their flocks. Effective health management involves a multi-faceted approach that includes vaccination programs, disease prevention strategies, and monitoring for early signs of illness.

Vaccination Programs for Broilers

Vaccination is a critical component of broiler health management. Vaccination programs help protect chickens from diseases that can significantly impact flock health and productivity. The choice of vaccine and the timing of vaccination depend on various factors, including the prevalence of specific diseases in the region and the type of production system.

Broiler producers should work closely with veterinarians to develop a vaccination program tailored to their specific needs.

Common Diseases and Prevention | Broiler Poultry

Broiler chickens are susceptible to various diseases, including respiratory infections, enteric diseases, and viral infections. Prevention is key to managing these diseases, and this can be achieved through a combination of good husbandry practices, biosecurity measures, and vaccination.

- Implementing strict biosecurity protocols to prevent the introduction and spread of disease.

- Maintaining a clean and dry environment to reduce the risk of disease.

- Monitoring flock health closely to detect early signs of illness.

Antibiotic-Free Production Methods

With the growing demand for antibiotic-free poultry products, producers are exploring alternative strategies to maintain flock health. These include the use of probiotics, prebiotics, and other non-antibiotic additives to promote gut health and enhance immune function.

Antibiotic-free production requires careful planning and management to minimize the risk of disease. Producers must balance the need to maintain flock health with the requirement to produce poultry without antibiotics.

Early Disease Detection Techniques

Early detection of disease is crucial for effective health management in broiler production. Producers should be vigilant for signs of illness, such as changes in behavior, reduced feed intake, or increased mortality.

Regular monitoring and record-keeping are essential for identifying potential health issues early. By detecting disease early, producers can take prompt action to prevent its spread and minimize its impact on the flock.

Poultry Litter Management Systems

The importance of proper poultry litter management cannot be overstated in broiler production. Effective litter management is crucial for maintaining a healthy environment for the chickens, controlling costs, and minimizing environmental impact.

Litter Material Selection and Quality

Selecting the right litter material is the first step in effective litter management. Common litter materials include pine shavings, straw, and sand. The chosen material should be dry, absorbent, and comfortable for the birds.

Key characteristics of good litter material:

- High absorbency

- Low cost

- Availability

- Comfort for the birds

Maintaining Optimal Litter Conditions

Maintaining optimal litter conditions is critical for the health and welfare of the broiler chickens. This involves ensuring the litter remains dry and friable.

Strategies for maintaining optimal litter conditions include:

- Regular monitoring of litter moisture

- Adequate ventilation in the poultry house

- Proper management of drinkers to prevent spillage

Waste Management and Environmental Considerations

Poultry litter management has significant environmental implications. Proper waste management practices are essential to minimize the environmental footprint of broiler farming.

| Waste Management Practice | Environmental Benefit |

|---|---|

| Composting | Reduces pathogens and weed seeds |

| Land application | Provides nutrients for crops |

| Proper storage | Prevents nutrient runoff |

Litter Reuse and Treatment Methods

Litter reuse is a common practice in broiler farming, offering economic and environmental benefits. However, it requires careful management to maintain litter quality and bird health.

Methods for treating reused litter include:

- Windrowing to reduce pathogens

- Cultivation to aerate the litter

- Treatment with litter amendments

By implementing effective poultry litter management systems, broiler farmers can improve bird health, reduce environmental impact, and enhance the overall sustainability of their operations.

Advanced Technologies in Broiler Production

Advanced technologies are transforming broiler production, enhancing efficiency, and improving animal welfare. The integration of these technologies is crucial for the sustainability and profitability of broiler farming operations.

Precision Livestock Monitoring Systems

Precision livestock monitoring involves the use of sensors and data analytics to track the health, growth, and behavior of broiler chickens in real-time. This technology enables farmers to identify potential issues early, reducing mortality rates and improving overall flock performance.

Automated Feeding and Watering Systems

Automated feeding and watering systems are designed to optimize feed consumption and water intake, crucial for the healthy growth of broilers. These systems can be programmed to dispense feed and water at optimal times, reducing waste and labor costs.

Climate Control Technologies

Maintaining an optimal climate is vital for broiler health and productivity. Advanced climate control technologies, including ventilation systems and temperature control, help in creating a stable environment within the broiler house, regardless of external weather conditions.

On-Farm Hatching Systems

On-farm hatching systems represent a significant advancement in broiler production, allowing for the hatching of chicks directly on the farm. This approach reduces the stress associated with chick transportation and can lead to improved chick health and survival rates.

The adoption of these advanced technologies in broiler production not only enhances operational efficiency but also contributes to improved animal welfare and reduced environmental impact. As the industry continues to evolve, the integration of technology will play a pivotal role in shaping the future of broiler farming.

Vertical Integration in Broiler Poultry Business

The concept of vertical integration is gaining traction in the broiler poultry business, offering a pathway to increased efficiency and profitability. Vertical integration involves controlling multiple stages of the production process, from breeding and hatching to growing and processing.

Understanding the Integrated Production Model

An integrated production model in broiler poultry involves managing all aspects of the business, including feed production, chicken growing, and processing. This approach allows for better control over quality, cost, and biosecurity.

Benefits of Integrated Production:

- Improved efficiency through streamlined operations

- Better quality control across all stages of production

- Enhanced biosecurity measures

- Potential for increased profitability

Contract Growing vs. Independent Production

Contract growing and independent production are two different approaches within the broiler poultry industry. Contract growers raise chickens under a contractual agreement with a poultry company, while independent producers manage their operations from start to finish.

| Aspect | Contract Growing | Independent Production |

|---|---|---|

| Financial Risk | Shared with the contractor | Borne by the producer |

| Market Access | Provided by the contractor | Must be established by the producer |

| Operational Control | Limited by the contract terms | Full control over operations |

Building Your Own Integrated Operation

Creating an integrated operation requires significant investment and planning. It involves developing or acquiring facilities for breeding, hatching, growing, and processing, as well as establishing a feed production system.

Partnerships and Cooperative Opportunities

For many producers, forming partnerships or cooperatives can be an effective way to achieve some benefits of vertical integration without the full investment. These collaborations can improve market access, share risk, and enhance bargaining power.

Key Considerations for Partnerships:

- Clear contractual agreements

- Defined roles and responsibilities

- Shared goals and objectives

- Mechanisms for conflict resolution

Financial Management for Broiler Farms

The financial management of broiler farms encompasses a broad range of activities, including budgeting, cost analysis, and profit optimization. Effective financial management is essential for ensuring the profitability and sustainability of broiler farming operations.

Start-up Costs and Capital Requirements

Initial investment is a critical aspect of starting a broiler farm. Start-up costs include expenses such as land acquisition, construction of poultry houses, purchase of equipment, and initial inventory of feed and chicks. The total start-up costs can vary significantly depending on the scale of the operation, ranging from a few thousand dollars for small backyard farms to hundreds of thousands of dollars for large commercial operations.

A detailed breakdown of start-up costs is essential for securing sufficient funding and ensuring the financial viability of the farm. This includes estimating costs for:

- Land preparation and infrastructure development

- Poultry house construction and equipment

- Initial stock of feed, chicks, and supplies

- Working capital for the first few months of operation

Operational Cost Analysis and Budgeting

Ongoing operational costs are a significant component of broiler farm expenses. These include feed costs, labor, veterinary care, and utilities. Conducting a thorough operational cost analysis helps farm managers identify areas where costs can be optimized without compromising the health and productivity of the flock.

Key areas to focus on in operational cost analysis include:

- Feed costs and efficiency

- Labor costs and productivity

- Veterinary care and health management

- Energy and utility expenses

Profit Margin Optimization Strategies

Profit margin optimization is crucial for maintaining the financial health of a broiler farm. This involves strategies to maximize revenue while minimizing costs. Key strategies include improving feed conversion ratios, reducing mortality rates, and optimizing market timing to secure better prices.

Farmers can also explore value-added products and niche markets to enhance profitability. Implementing efficient production practices and investing in technology can further contribute to improved profit margins.

Return on Investment Calculations

Calculating the return on investment (ROI) is essential for evaluating the financial performance of a broiler farm. ROI calculations help farmers understand the profitability of their investment and make informed decisions about future investments or adjustments to their operations.

To calculate ROI, farmers need to consider both the initial investment and ongoing expenses, as well as the revenue generated from the sale of broilers or broiler products. A positive ROI indicates that the farm is financially viable, while a negative ROI suggests areas that need improvement.

Marketing and Selling Broiler Products

To stand out in the competitive poultry market, broiler farms must adopt innovative marketing strategies. Effective marketing and sales techniques are crucial for maximizing profits and ensuring the long-term sustainability of broiler operations.

Direct Marketing Strategies

Direct marketing allows broiler farmers to connect directly with consumers, potentially increasing profit margins. Some effective direct marketing strategies include:

- Developing a strong online presence through social media and farm websites

- Participating in farmers’ markets and local food events

- Implementing community-supported agriculture (CSA) programs

- Creating farm-to-table partnerships with local restaurants

Wholesale and Retail Channels

While direct marketing can be lucrative, many broiler farms also rely on wholesale and retail channels to distribute their products. Key considerations for these channels include:

- Building relationships with distributors and wholesalers

- Ensuring consistent product quality and supply

- Negotiating favorable pricing and payment terms

- Complying with regulatory requirements for wholesale and retail sales

Value-Added Product Opportunities

Creating value-added products can help broiler farms differentiate themselves and command higher prices. Some examples include:

- Marinated or seasoned chicken products

- Organic or free-range chicken options

- Pre-cooked or ready-to-eat chicken meals

- Specialty products like heritage or slow-growing breeds

Organic and Specialty Market Premiums

Targeting organic and specialty markets can provide significant premiums for broiler farms. To capitalize on these opportunities, farms should:

- Obtain necessary certifications for organic or specialty production

- Develop marketing materials highlighting the unique aspects of their products

- Identify and target consumers willing to pay premiums for these products

- Ensure consistent supply and quality to maintain market share

By diversifying their marketing strategies and exploring various sales channels, broiler farms can improve their profitability and build a resilient business model.

Building a Sustainable and Profitable Broiler Business

Creating a thriving broiler business requires a multifaceted approach that balances profitability with sustainability. By implementing efficient management practices, prioritizing animal welfare, and adopting environmentally friendly strategies, producers can establish a successful and responsible operation.

A sustainable broiler business is built on a foundation of careful planning, precise execution, and ongoing improvement. This includes selecting the right chicken breeds, optimizing feed conversion ratios, and maintaining high standards of biosecurity and health management.

To achieve long-term profitability, broiler producers must stay attuned to market trends, manage finances effectively, and explore opportunities for value-added products and niche markets. By integrating these elements, farmers can create a profitable broiler business that is resilient and adaptable to changing market conditions.

Ultimately, a well-managed broiler operation not only contributes to the local economy but also plays a vital role in meeting the demand for high-quality poultry products while promoting sustainable agricultural practices.

FAQ

What is broiler chicken farming?

Broiler chicken farming is the practice of raising chickens specifically for meat production. It involves breeding, feeding, and caring for chickens until they are ready for market.

What are the benefits of broiler chicken farming?

Broiler chicken farming can be a profitable venture, providing a source of income for farmers and contributing to the local economy. It also helps to meet the demand for protein-rich food.

What are the different breeds of broiler chickens?

There are several breeds of broiler chickens, including commercial varieties like Ross 308 and Cobb 500, as well as heritage breeds like Plymouth Rock and Brahma.

How do I design a broiler poultry house?

Designing a broiler poultry house involves considering factors like ventilation, temperature control, and space requirements. The house should be well-insulated, dry, and free from drafts.

What is the optimal feeding program for broilers?

A typical broiler feeding program consists of three phases: starter, grower, and finisher. The feed is formulated to meet the nutritional needs of the chickens at different stages of growth.

How can I optimize feed conversion ratio in broilers?

Optimizing feed conversion ratio (FCR) involves providing high-quality feed, maintaining a healthy environment, and monitoring growth rates. Nutritional strategies like using enzymes and optimizing nutrient levels can also help.

What are the key factors in broiler chick brooding?

Broiler chick brooding involves providing a warm, safe, and healthy environment for young chicks. Key factors include temperature and humidity control, adequate ventilation, and proper feeding and watering.

How can I maintain biosecurity on my broiler farm?

Maintaining biosecurity involves creating a comprehensive biosecurity plan, controlling access to the farm, and implementing disease prevention strategies like vaccination and sanitation.

What are the common diseases affecting broilers?

Common diseases affecting broilers include coccidiosis, respiratory diseases, and necrotic enteritis. Implementing vaccination programs and maintaining good hygiene practices can help prevent these diseases.

How can I manage poultry litter effectively?

Effective poultry litter management involves selecting the right litter material, maintaining optimal litter conditions, and implementing waste management strategies.

What are the benefits of using advanced technologies in broiler production?

Advanced technologies like precision livestock monitoring, automated feeding and watering systems, and climate control technologies can improve efficiency, reduce costs, and enhance animal welfare.

How can I market and sell my broiler products?

Marketing and selling broiler products involve identifying target markets, developing a marketing strategy, and establishing relationships with buyers. Value-added product opportunities and organic or specialty market premiums can also be explored.

What are the financial considerations for starting a broiler farm?

Starting a broiler farm involves considering start-up costs, operational expenses, and potential revenue. Financial planning and budgeting are essential to ensure the viability of the business.

What is vertical integration in the broiler poultry business?

Vertical integration involves controlling multiple stages of the production process, from breeding to processing. This can help improve efficiency, reduce costs, and enhance profitability.

How can I ensure the sustainability of my broiler business?

Ensuring the sustainability of a broiler business involves implementing environmentally friendly practices, maintaining good animal welfare, and ensuring the long-term viability of the operation.

Conclusion of: Broiler Poultry Farming Business

Broiler Poultry farming is one of the most dynamic and profitable segments in U.S. agriculture. The keyword Broiler Poultry appears right away to align with SEO goals. Whether you’re entering the industry or scaling up, adopting efficient Broiler Poultry methods can dramatically improve your bottom line. Learn more about broiler farming economics from USDA.

Why Broiler Poultry Business Is So Profitable

Broiler Poultry farming delivers rapid turnaround. Modern Broiler Poultry breeds reach processing weight in just five to seven weeks, enabling multiple cycles per year and swift returns. High demand for chicken meat in the U.S. drives consistent market pricing and volume sales. Optimizing Broiler Poultry operations can yield slim but steady margins per pound, which scale into substantial earnings across large flocks. Explore poultry market trends from the National Chicken Council.

Selecting High-Yield Broiler Poultry Strains

Success in Broiler Poultry business depends heavily on genetics. Cornish Cross and Ross breeds dominate U.S. production due to superior growth rates, feed conversion ratios around 1.6 kg feed per kg live weight, and excellent breast meat yields. Using quality Broiler Poultry chicks from reputable hatcheries ensures uniform growth, reduced mortality, and improved overall performance. See breed comparisons from the University of Georgia Extension.

Efficient Housing and Environmental Control

Proper livestock environments are essential for Broiler Poultry health and performance. Maintain house temperature starting around 90°F and gradually reducing to about 70°F by week 5 to 7. Good ventilation reduces ammonia buildup—a common risk factor in Broiler Poultry houses—and controls moisture in bedding to around 25–35%. Uniform feeder and waterer access improves flock uniformity and performance. Best practices from Penn State Extension.

Feed Management and Nutrition Strategies

In Broiler Poultry operations, feed cost is typically 60–70% of variable expenses. Use staged feeds (starter, grower, finisher) formulated with high-protein, balanced amino acids, corn and soybean meal base. Implement feed additives like probiotics, phytase, or enzymes to aid digestion and reduce overall feed consumption, thus improving feed conversion ratio in your Broiler Poultry business. Nutrition guidelines from Mississippi State University.

Biosecurity and Disease Prevention

Strong biosecurity is critical in Broiler Poultry enterprises. Minimize disease risk through all-in/all-out flock cycles, strict sanitation, footbaths for visitors, and rodent control. Monitor flock mortality and health trends weekly to detect issues early. Healthy Broiler Poultry flocks reduce losses, feed waste, and carryovers of common diseases like coccidiosis or avian influenza. CDC biosecurity protocols.

Litter Management and House Sanitation

Managing poultry litter is vital in Broiler Poultry production. Use absorbent bedding (pine shavings, rice hulls) to limit moisture and ammonia. Replace caked areas between flocks, and consider litter amendments like acidifiers or microbial treatments to reduce ammonia and odor. Proper Broiler Poultry litter management improves welfare and feed conversion, lowering overall production risks. EPA guidelines on poultry litter.

Monitoring and Precision Livestock Farming

Precision livestock farming tools are increasingly used in Broiler Poultry businesses. Sensors, cameras, and audio monitoring systems track flock behavior, feed intake, temperature, and humidity. These tools can detect anomalies—such as huddling, inactivity, or increased mortality—enabling swift corrective measures. Such modern Broiler Poultry approaches boost productivity and profitability. Research from the University of Arkansas.

Contract Systems vs. Independent Operation

Broiler Poultry producers often work within integrated, vertically coordinated systems run by processors like Tyson or Perdue. Under contract, growers receive chicks, feed, and veterinary support in return for growing birds to company standards. Tournament-style pay rewards efficiency. Alternatively, independent Broiler Poultry farming allows more control over pricing and marketing but carries more market risk and overhead. Economic analysis from Auburn University.

Scaling and Capacity Planning

To scale Broiler Poultry operations, careful planning is essential. Backyard setups of a few hundred birds can evolve into commercial farms with tens of thousands per flock. To support this, ensure you have reliable infrastructure: climate-controlled houses, feed bins, water systems, and waste handling. Increasing scale in Broiler Poultry business amplifies profit potential but also magnifies management responsibility. Farm expansion tips from Purdue Extension.

Economic Considerations and Profit Margins

A typical Broiler Poultry operation aims for narrow margins—roughly $0.10–0.15 per pound of live weight. With birds averaging 5.5 lbs live weight, that equates to around $4,000–6,000 in profit per 10,000-bird flock, depending on mortality and pricing. Careful monitoring of feed costs, chick pricing, and processing fees helps optimize Broiler Poultry profitability. USDA poultry cost and returns.

Welfare and Ethical Practices

Ethical considerations in Broiler Poultry business increasingly influence consumer demand. Growing pressure to reduce antibiotic use has led many producers to adopt antibiotic-free or organic practices. On-farm hatching, which provides immediate access to feed and water, shows promise for improving chick welfare and lowering mortality in Broiler Poultry flocks. Good welfare ultimately supports better growth and market appeal. Animal welfare standards from AVMA.

Risk Management and Market Fluctuations

Risk in Broiler Poultry business comes from disease outbreaks, volatile feed prices, or processing plant closures. For example, facility shutdowns by major integrators have forced some growers in the U.S. to consider switching to egg production or diversifying operations. Strong contingency planning and diversified marketing help sustain Broiler Poultry enterprises. Risk management tools from USDA.

Sustaining Efficiency With Innovation

To stay competitive, Broiler Poultry operators adopt innovations such as robotics, behavior-detecting AI frameworks, and enhanced disease surveillance. Automation reduces labor costs and stress on birds, while data-driven decisions support continuous improvement. These efficient Broiler Poultry innovations maximize output, reduce losses, and support higher margins. Innovations from the Poultry Science Association.

Marketing and Market Channels

Broiler Poultry producers in the U.S. sell via integrated processors, direct farm sales, live-bird markets, or wholesalers. Premium market segments include antibiotic-free, organic, or slow-grown birds marketed to discerning consumers. Direct-to-consumer or CSA models may allow better margins—but require strong branding and compliance with USDA inspection for retail sales. Marketing strategies from SARE.

Final Thought

Effective Broiler Poultry business relies on tight control of genetics, environment, nutrition, sanitation, and market channels. Focusing on performance metrics—feed conversion, mortality, growth rates—and embracing new tools like precision livestock farming and welfare-enhancing practices enable you to build a profitable, sustainable enterprise. With careful planning and operational discipline, Broiler Poultry farming in the U.S. offers a robust opportunity for both small-scale and commercial producers.