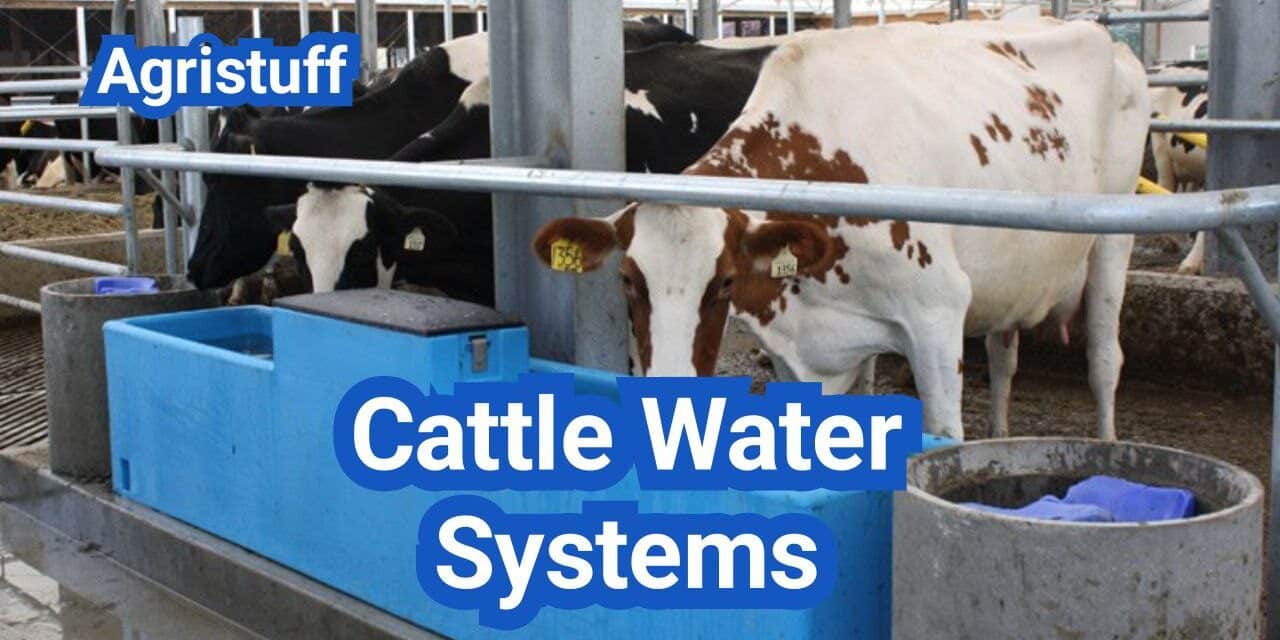

Providing clean cattle water is crucial for the health and productivity of livestock. A well-designed cattle water system ensures that animals have access to fresh water at all times.

The design of such systems involves careful consideration of flow rates and trough sizing to meet the needs of the cattle. In addition, winter freeze control is essential to prevent water from freezing, especially in colder climates.

A properly functioning livestock watering system is vital for maintaining the overall health of the cattle. By understanding the key components of these systems, farmers and livestock managers can make informed decisions to optimize their operations.

Key Takeaways

- Clean water is essential for cattle health and productivity.

- A well-designed cattle water system ensures access to fresh water.

- Flow rates and trough sizing are critical components of the system.

- Winter freeze control is necessary to prevent water from freezing.

- A properly functioning livestock watering system is vital for cattle health.

Cattle Water Requirements and Consumption Factors

Cattle water needs are influenced by various factors, including the type and weight of the cattle, as well as environmental conditions. Understanding these factors is crucial for ensuring that cattle have adequate access to water, which is essential for their health and productivity.

Daily Water Intake Needs by Cattle Type and Weight

The daily water intake of cattle varies significantly based on their type and weight. Generally, larger cattle require more water due to their greater body mass. For instance, lactating cows and beef cattle have different water needs compared to calves or non-lactating cows.

According to research, the daily water intake for cattle can range from approximately 10 to over 30 gallons per head, depending on factors such as the cattle’s size, age, and production level. For example, a lactating dairy cow may require up to 25 gallons of water per day, while a beef cow might need around 15 gallons daily.

| Cattle Type | Weight (lbs) | Daily Water Intake (gallons) |

|---|---|---|

| Beef Cow | 1000 | 10-15 |

| Lactating Dairy Cow | 1200 | 20-25 |

| Calves | 200 | 2-4 |

Seasonal Temperature Effects on Water Consumption

Seasonal temperature fluctuations significantly impact cattle water consumption. During hot weather, cattle tend to drink more water to stay cool and maintain their bodily functions. Conversely, in colder temperatures, their water intake may decrease.

Research indicates that beef cattle water intake can increase by up to 50% during hot summer months compared to cooler winter periods. This variation highlights the importance of ensuring that water supply systems can meet the increased demand during peak temperature periods.

Water Access Impact on Cattle Health and Production

Adequate access to clean water is vital for maintaining cattle health and optimizing production. Limited water access can lead to dehydration, reduced feed intake, and decreased productivity.

Ensuring that cattle have unrestricted access to water is crucial, especially during periods of high demand such as hot weather or when cattle are lactating. Proper waterer sizing and placement are key factors in providing adequate water access.

Essential Components of Effective Cattle Water Systems

Cattle water systems play a vital role in livestock management, requiring careful consideration of several key components. An effective system ensures that cattle have consistent access to clean water, which is crucial for their health and productivity.

Water Sources: Wells, Ponds, and Municipal Supplies

The choice of water source is a critical aspect of designing a cattle watering system. Common water sources include:

- Wells: Providing a reliable source of groundwater, wells can be a good option if the water quality is suitable for cattle consumption.

- Ponds: Surface water sources like ponds can be used, but they require careful management to prevent contamination.

- Municipal Supplies: In some cases, using municipal water supplies can be an option, especially for operations near urban areas.

Each water source has its advantages and disadvantages. For instance, wells can provide high-quality water but may require significant investment in drilling and pumping equipment. Ponds, on the other hand, are less expensive to establish but may need additional treatment to ensure water quality.

Delivery Systems: Gravity-Fed vs. Pressurized

The delivery system is another crucial component, with two primary options: gravity-fed and pressurized systems.

- Gravity-Fed Systems: These systems rely on gravity to distribute water from the source to the cattle. They are often less expensive to operate and maintain.

- Pressurized Systems: Pressurized systems use pumps to deliver water under pressure, allowing for more flexibility in system design and placement of water troughs.

The choice between gravity-fed and pressurized systems depends on the topography of the land, the distance between the water source and the cattle, and the specific needs of the operation.

NRCS Watering Facility Standard 614 Guidelines

The Natural Resources Conservation Service (NRCS) provides guidelines for designing and implementing effective cattle watering systems through its Watering Facility Standard 614. These guidelines cover aspects such as:

- Water source development

- Water storage and delivery systems

- Trough sizing and placement

- System maintenance and management

Following NRCS guidelines can help ensure that cattle watering systems are both effective and environmentally sustainable. By adhering to these standards, farmers and ranchers can improve the health and productivity of their cattle while protecting natural resources.

Calculating Proper Flow Rates for Your Herd

The key to a successful cattle watering system lies in understanding and calculating the proper flow rate for your herd’s needs. Ensuring that your cattle have access to sufficient water is crucial for their health and productivity.

Determining GPM Requirements Based on Herd Size

To determine the gallons per minute (GPM) required for your herd, you need to consider the size of your cattle population. A general guideline is to provide at least 1-2 gallons per minute per 100 head of cattle, depending on factors such as age, size, and breed. For instance, a larger herd or one consisting of lactating cows may require a higher flow rate to meet their increased water needs.

Peak Demand Considerations During Hot Weather

During hot weather, cattle consume more water, leading to peak demand periods. It’s essential to account for these fluctuations when designing your watering system. Typically, cattle water consumption can increase by 50% or more during extreme heat, necessitating a higher flow rate to prevent water shortages.

Minimum Flow Rate Standards for Cattle Satisfaction

Establishing a minimum flow rate standard is vital to ensure cattle satisfaction and prevent competition for water resources. The Natural Resources Conservation Service (NRCS) provides guidelines for minimum flow rates, recommending at least 0.5 to 1.0 gallons per minute per watering location. Ensuring that your system meets or exceeds these standards is crucial for maintaining cattle health and productivity.

By understanding and implementing the correct flow rate for your cattle herd, you can ensure that your watering system is efficient, effective, and meets the needs of your cattle. This not only improves cattle health but also contributes to the overall productivity and sustainability of your operation.

Water Trough Sizing and Placement Guidelines

Adequate water trough sizing and thoughtful placement are essential components of a well-managed cattle operation. Properly sized and positioned water troughs ensure that cattle have consistent access to clean water, which is vital for their health and productivity.

Space Requirements Per Head of Cattle

When determining the appropriate size for water troughs, it’s crucial to consider the number of cattle that will be using them. A general guideline is to provide at least 1-2 inches of trough space per head of cattle. This ensures that all animals can access water simultaneously, reducing competition and stress within the herd.

Optimal Trough Height and Access Considerations

The height and accessibility of water troughs significantly impact cattle comfort and water consumption. Optimal trough height should be between 24 and 32 inches, allowing cattle to drink comfortably without straining their necks. Additionally, troughs should be designed to minimize spillage and contamination.

Strategic Placement for Grazing Management

Strategic placement of water troughs is critical for effective grazing management. Troughs should be located in areas that encourage even grazing distribution, reducing the risk of overgrazing near water sources. It’s also important to consider the proximity to shade, as cattle often prefer to rest and drink in shaded areas.

| Aspect | Guideline | Benefit |

|---|---|---|

| Trough Space per Head | 1-2 inches | Reduces competition |

| Trough Height | 24-32 inches | Improves cattle comfort |

| Placement Strategy | Near shade, away from sensitive areas | Enhances grazing distribution |

Selecting the Right Water Tank Materials

The selection of water tank materials significantly impacts the durability and efficiency of cattle watering systems. When choosing a water tank, it’s essential to consider the pros and cons of different materials.

Concrete vs. Metal vs. Plastic Options

Cattle water tanks can be made from various materials, each with its advantages and disadvantages. Concrete tanks are durable and can last for decades but are heavy and may require additional support. Metal tanks are versatile and can be made from materials like steel or aluminum, but they may corrode over time. Plastic tanks are lightweight and resistant to corrosion, but they can be prone to damage from UV light and extreme temperatures.

When deciding on the material, it’s crucial to weigh these factors against the specific needs of your cattle operation.

Durability Factors for Different Environments

The durability of a water tank is influenced by its environment. For instance, tanks exposed to direct sunlight may require UV-resistant materials, while those in coastal areas may need to withstand salt corrosion. Understanding the local climate and environmental conditions is crucial for selecting a tank that will last.

Cost Comparison and Lifespan Expectations

The cost of cattle water tanks varies significantly based on the material. While concrete tanks may have a higher upfront cost, their long lifespan can make them more economical in the long run. Plastic tanks, though potentially cheaper initially, may need to be replaced more frequently. A thorough cost-benefit analysis is necessary to determine the most cost-effective option.

By considering both the initial cost and the expected lifespan, farmers can make an informed decision that balances budget constraints with the need for a reliable water supply.

Pipeline Design for Livestock Watering Systems

The NRCS 516 Livestock Pipeline Standards provide a framework for designing efficient livestock watering systems. These standards are crucial for ensuring that pipelines are constructed to meet the needs of livestock while minimizing environmental impact.

NRCS 516 Livestock Pipeline Standards

The NRCS 516 standards outline specific requirements for the design and installation of livestock pipelines. These include guidelines for pipe sizing, material selection, and burial depth to ensure that pipelines can withstand various environmental conditions and livestock pressures.

When designing a pipeline system, it’s essential to consider the NRCS 516 standards to ensure compliance and effectiveness. The standards help in planning a system that is both durable and efficient.

Pipe Sizing, Material Selection, and Burial Depth

Proper pipe sizing is critical to ensure that the pipeline can supply enough water to meet the demands of the livestock. The size of the pipe will depend on the number of animals, the distance from the water source, and the flow rate required.

Material selection is another crucial factor. Common materials include PVC, HDPE, and steel, each with its advantages and disadvantages. For example, HDPE is known for its durability and resistance to corrosion, making it a popular choice for livestock watering systems.

The burial depth of the pipeline is also important to prevent freezing and damage from livestock or farm equipment. Generally, pipelines should be buried below the frost line to prevent freezing.

Pressure Regulation and System Layout Planning

Pressure regulation is vital to prevent damage to the pipeline and ensure that water is delivered at a suitable pressure for the livestock watering system. This may involve the use of pressure-reducing valves or regulators.

Effective system layout planning involves considering the topography of the land, the location of the water source, and the distribution points for the livestock. A well-planned system will minimize the need for pumps and reduce energy costs.

By following the NRCS 516 standards and considering factors such as pipe sizing, material selection, and pressure regulation, farmers and ranchers can design effective livestock watering systems that meet the needs of their animals while minimizing environmental impact.

Installing Automatic Cattle Waterers Step-by-Step

To ensure the health and productivity of your cattle, it’s essential to install automatic cattle waterers correctly. This process involves several critical steps that, when followed, will provide your herd with a reliable source of clean water.

Site Preparation and Foundation Requirements

Before installing an automatic cattle waterer, the site must be properly prepared. This includes selecting a location that is easily accessible for your cattle and has a suitable foundation to support the waterer. The ground should be level, and the area should be cleared of any debris or obstructions.

The foundation requirements may vary depending on the type and size of the waterer. For instance, larger waterers may require a concrete base to prevent tipping and ensure stability. It’s crucial to follow the manufacturer’s guidelines for specific foundation requirements.

Water and Electrical Connection Procedures

Once the site is prepared, the next step involves connecting the waterer to a water supply and, if necessary, to an electrical source. For installation procedures, it’s vital to follow local plumbing codes and regulations. This may include using appropriate piping materials and ensuring that all connections are secure and leak-free.

If the waterer requires electricity, the connection should be made in accordance with local electrical codes, using the correct wiring and protective devices such as GFCI outlets to prevent electrical shock.

Float Valve Adjustment and System Testing

A critical component of an automatic cattle waterer is the float valve, which regulates the water level. Adjusting the float valve correctly is essential to ensure that the waterer fills to the appropriate level without overflowing. The manufacturer’s instructions should be consulted for specific guidance on float valve adjustment.

After installation, the entire system should undergo thorough system testing to verify that it is functioning as intended. This includes checking for leaks, ensuring the waterer fills and shuts off correctly, and verifying that the electrical components are working properly.

By following these steps and guidelines, you can ensure a successful installation of your automatic cattle waterer, providing your cattle with a reliable and clean source of water.

Energy-Free and Frost-Free Watering Solutions

Utilizing ground heat, energy-free waterers provide a sustainable and efficient way to keep water from freezing in cold temperatures. These innovative systems are designed to harness the natural heat from the earth, providing a reliable source of unfrozen water for cattle even in the harshest winter conditions.

How Energy-Free Waterers Utilize Ground Heat

Energy-free cattle waterers work by leveraging the earth’s natural heat to keep water from freezing. This is typically achieved through a design that allows the water to be stored in a deeper, insulated tank or pipe buried underground, where the earth’s natural temperature keeps the water from freezing.

The system’s effectiveness relies on the principle that the earth’s temperature below the frost line remains relatively constant and warm enough to prevent water from freezing. By using this natural heat, these systems can operate without the need for electricity, making them an attractive option for farmers looking to reduce their energy costs.

Installation Requirements for Maximum Frost Prevention

To maximize the effectiveness of energy-free waterers, proper installation is crucial. This includes burying the water storage and delivery components below the frost line to ensure they are insulated by the earth’s natural warmth.

The specific installation requirements can vary depending on factors such as climate, soil type, and the size of the operation. However, key considerations include ensuring the system is well-insulated, selecting materials that can withstand cold temperatures, and designing the system to minimize the risk of freezing.

Best Practices for Energy-Free System Management

Managing an energy-free cattle watering system involves regular maintenance to ensure it operates effectively. This includes checking the system regularly for signs of freezing or damage, ensuring that the insulation remains intact, and making adjustments as necessary to accommodate changing weather conditions.

Additionally, farmers should monitor water consumption patterns to identify any potential issues early. By following these best practices, farmers can ensure their energy-free watering systems continue to provide a reliable source of water for their cattle throughout the year.

Winter Freeze Prevention and Management

Ensuring cattle have access to water during winter is crucial, requiring innovative freeze prevention and management techniques. Effective winter management of cattle water systems is vital for maintaining herd health and productivity.

Effective Insulation Techniques

Insulating water lines and tanks is a fundamental step in preventing freeze. Foam pipe insulation and wrapping tanks with insulation materials can significantly reduce the risk of freezing. “Proper insulation is key to maintaining water flow during cold snaps,” according to agricultural experts.

The use of thermal mass, such as large, dark-colored tanks, can also help absorb heat during the day and release it at night, keeping water from freezing.

Heating Element Options and Safety

For extreme cold conditions, incorporating heating elements into cattle water systems can be an effective solution. Submersible water heaters and thermostatically controlled heaters are popular options. It’s crucial to ensure that all electrical components are safely installed and protected from the elements to prevent accidents.

- Submersible heaters that are designed for livestock waterers

- Thermostatically controlled heaters that turn on only when necessary

- Heating elements specifically designed for outdoor use

Emergency Procedures for Extreme Cold

Despite preventive measures, extreme cold events can still cause issues. Having an emergency plan in place is essential. This may include having backup water sources, such as portable water tanks, and being prepared to manually intervene to ensure cattle have access to water.

“Farmers must be prepared to adapt their watering systems to extreme weather conditions to protect their livestock,” says a veteran cattle farmer.

Regular monitoring of water systems during cold snaps and being ready to implement emergency measures can make a significant difference in maintaining cattle health.

Top Commercial Cattle Waterer Options

Cattle farmers have numerous options when choosing commercial waterers, with brands like Ritchie and Miraco leading the way. The right waterer can significantly impact cattle health and farm productivity.

Ritchie Automatic Waterers: Features and Models

Ritchie automatic waterers are renowned for their durability and effectiveness in various climates. These waterers are designed to provide a constant supply of clean water to cattle, minimizing the need for manual intervention.

- Durable Construction: Built to withstand harsh weather conditions and heavy use.

- Easy Installation: Simple to install and integrate into existing watering systems.

- Low Maintenance: Designed for minimal maintenance, reducing labor costs.

Some popular models include the Ritchie Tank Waterer and the Ritchie Trough Waterer, each offering unique features tailored to different farm setups.

Miraco, Little Giant, and Other Leading Brands

Besides Ritchie, other notable brands in the commercial cattle waterer market include Miraco and Little Giant. These brands offer a range of products with varying features and benefits.

Miraco waterers are known for their innovative designs and energy-efficient operation. Little Giant waterers, on the other hand, are praised for their versatility and ease of use.

| Brand | Model | Key Features | Price Range |

|---|---|---|---|

| Ritchie | Tank Waterer | Durable, easy to clean | $200-$500 |

| Miraco | Energy-Efficient Waterer | Innovative design, low energy consumption | $300-$600 |

| Little Giant | Versatile Trough | Easy to install, versatile | $150-$400 |

Comparing Features, Durability, and Price Points

When selecting a commercial cattle waterer, it’s essential to compare the features, durability, and price points of different models. Factors to consider include the material used, ease of maintenance, and the specific needs of your cattle.

For instance, Ritchie waterers are often praised for their durability, while Miraco waterers stand out for their energy efficiency. Little Giant waterers offer versatility and ease of use.

Ultimately, the best livestock waterer for your farm will depend on your specific needs, including the size of your herd, climate conditions, and budget. By carefully evaluating the options and considering factors such as durability and maintenance requirements, you can make an informed decision that benefits your cattle and your bottom line.

Heavy Use Area Protection Around Water Points

Effective cattle water systems must include strategies for protecting the areas around water points from the impacts of heavy use. “The integrity of the land and the health of the cattle depend on it,” as noted by agricultural experts. Heavy use area protection is crucial for preventing erosion, maintaining water quality, and ensuring cattle have consistent access to clean water.

Surface Material Options

Choosing the right surface material is critical for heavy use area protection. Options include:

- Concrete: Durable and easy to clean, but can be expensive and may require additional drainage considerations.

- Gravel: Allows for good drainage and is generally less expensive than concrete, but may require more frequent maintenance.

- Geotextiles: Can be used to stabilize soil and prevent erosion, especially in areas with heavy rainfall or where vegetation is sparse.

Drainage Design

Proper drainage is essential for preventing mud and erosion around water points. A well-designed drainage system should:

- Direct water away from the water point and surrounding areas.

- Use natural or constructed channels to manage runoff.

- Incorporate features like culverts or French drains as necessary.

As Ritchie, a leading brand in automatic waterers, suggests, “A good drainage system is key to maintaining a clean and healthy environment for cattle.”

Maintenance Protocols

Regular maintenance is vital for the longevity and effectiveness of heavy use area protection measures. This includes:

- Regular inspections to identify and address wear and tear.

- Cleaning and repairing drainage systems as needed.

- Replenishing or repairing surface materials to maintain their integrity.

By implementing these strategies, farmers can protect heavy use areas around water points, enhancing both cattle health and environmental sustainability.

Water Quality Management for Optimal Cattle Health

Cattle health is significantly influenced by the quality of water they consume, making water quality management a vital aspect of livestock care. Poor water quality can lead to reduced productivity, health issues, and even mortality in severe cases.

Testing Protocols for TDS, Nitrates, and Sulfates

Regular testing of water quality is essential to identify potential contaminants. Key parameters to test include Total Dissolved Solids (TDS), nitrates, and sulfates. TDS measures the total amount of dissolved substances in water, while nitrates and sulfates can be harmful to cattle at high concentrations.

Testing protocols should be implemented regularly, especially before introducing new water sources to the cattle. Laboratories can provide detailed analysis, helping farmers make informed decisions about water treatment.

Acceptable Parameter Ranges for Cattle Consumption

Understanding the acceptable ranges for water quality parameters is crucial for ensuring cattle health. The following table outlines the general guidelines for TDS, nitrates, and sulfates:

| Parameter | Acceptable Range | Potential Issues |

|---|---|---|

| TDS (mg/L) | 0 – 5,000 | Higher levels may cause digestive issues |

| Nitrates (mg/L) | 0 – 100 | Levels above 100 mg/L can be toxic |

| Sulfates (mg/L) | 0 – 1,000 | High levels can cause diarrhea and other health issues |

Treatment Options for Common Water Quality Issues

When water quality issues are identified, treatment options must be considered. Common treatments include:

- Reverse osmosis for reducing TDS

- Ion exchange systems for removing nitrates and sulfates

- Filtration systems to remove particulate matter and contaminants

Implementing these treatment options can significantly improve water quality, ensuring that cattle have access to clean, safe drinking water. Regular monitoring and maintenance of these systems are crucial to their effectiveness.

Cleaning and Maintaining Cattle Water Systems

Maintaining clean cattle water systems is crucial for the health and productivity of your herd. Regular maintenance not only ensures the water quality but also prolongs the lifespan of the watering equipment.

Seasonal Cleaning Schedules and Procedures

Developing a seasonal cleaning schedule is essential for maintaining optimal water quality. In the spring and summer, when cattle are more active, water troughs and tanks should be cleaned more frequently to prevent algae buildup. A thorough cleaning involves draining the system, scrubbing all surfaces with a suitable detergent, and rinsing thoroughly.

In the fall and winter, the focus shifts to preventing freeze damage and ensuring that the water remains unfrozen and accessible. Regular inspections during these seasons can help identify potential issues before they become critical.

Algae Control Methods and Products

Algae growth is a common issue in cattle water systems, particularly during warmer months. Effective algae control involves a combination of regular cleaning, using algaecides, and implementing preventive measures such as shading water tanks or using algae-resistant materials.

There are various algaecide products available that are safe for use in cattle water systems. When selecting an algaecide, it’s crucial to choose a product that is effective against the type of algae present and safe for cattle consumption.

Troubleshooting Common System Problems

Despite regular maintenance, issues can arise with cattle water systems. Common problems include clogged pipes, faulty float valves, and leaks. Troubleshooting these issues promptly is essential to minimize downtime and ensure continuous access to clean water for the cattle.

Regular inspections can help identify potential issues early. For instance, checking for signs of wear on float valves and inspecting pipes for damage can prevent more significant problems from developing.

Cost Analysis and Return on Investment

Understanding the cost considerations and return on investment (ROI) of cattle watering systems is crucial for ranchers looking to optimize their operations. A comprehensive cost analysis involves evaluating both the initial expenses associated with installing a cattle watering system and the ongoing costs of maintaining it.

Initial Installation Costs vs. Long-Term Benefits

The initial investment in a cattle watering system can be significant, encompassing costs such as:

- Equipment purchases (water tanks, troughs, pipes)

- Installation labor

- Site preparation

However, the long-term benefits often outweigh these initial expenses. Improved water access can lead to increased cattle health and productivity, ultimately enhancing the overall profitability of the ranch.

Energy and Maintenance Cost Factors

Ongoing costs associated with cattle watering systems include energy expenses for pumping water and maintenance costs to ensure the system’s longevity. The choice of energy source and the efficiency of the system’s design can significantly impact these costs.

Key factors influencing energy and maintenance costs:

- System design and efficiency

- Energy source (e.g., solar, electricity, fossil fuels)

- Regular maintenance schedules

Productivity Improvements from Optimal Water Access

Optimal water access is critical for maintaining cattle health and productivity. Studies have shown that cattle with reliable access to clean water exhibit improved weight gain and milk production. By investing in a well-designed cattle watering system, ranchers can potentially see a significant return on investment through increased productivity.

In conclusion, while the initial costs of a cattle watering system may seem daunting, the long-term benefits and potential for increased productivity make it a valuable investment for ranchers. By carefully considering cost factors and optimizing system design, ranchers can achieve a strong return on investment.

Building Resilient and Efficient Cattle Water Systems

Building resilient and efficient cattle water systems is crucial for optimal cattle health and productivity. By understanding cattle water requirements and consumption factors, producers can design systems that meet the needs of their herd.

Proper flow rates, trough sizing, and winter freeze control are essential components of effective cattle water systems. Implementing energy-free and frost-free watering solutions can also help reduce maintenance costs and improve system reliability.

By following guidelines from the NRCS and considering factors such as water quality, pipeline design, and heavy use area protection, producers can create resilient cattle water systems that withstand environmental challenges.

Efficient cattle water systems not only improve cattle health but also contribute to increased productivity and reduced operational costs. By investing in well-designed and well-maintained water systems, producers can reap long-term benefits and improve their overall operation.

FAQ

Why is water so important for cattle?

Water is crucial for cattle health and productivity, influencing their overall well-being, growth, and milk production.

What types of livestock waterers are available?

Various types of livestock waterers are available, including automatic waterers, energy-free waterers, electric and insulated waterers, and heated options for cold climates.

How do automatic waterers work?

Automatic waterers use a float valve to refill the water tank as cattle drink, ensuring a constant water supply.

What features should I look for in a quality livestock waterer?

Key features to consider include durability, water capacity, flow rate, ease of cleaning, and frost protection.

How do I prevent livestock waterers from freezing in winter?

To prevent freezing, use insulation techniques, heating elements, or energy-free waterers that utilize ground heat.

How often should livestock waterers be cleaned?

Regular cleaning is essential; the frequency depends on factors like usage, environment, and the presence of algae or contaminants.

What is the return on investment for quality livestock waterers?

Quality livestock waterers can improve cattle health and productivity, leading to increased profitability for farmers.

Which livestock waterer is best for large herds?

For large herds, consider waterers with high capacity and flow rates, such as those from Ritchie or Nelson.

Are portable waterers a good option for rotational grazing?

Yes, portable waterers are suitable for rotational grazing, allowing for flexible placement and management of grazing areas.

How do I size a waterer for my livestock herd?

To size a waterer, consider the number of cattle, their water requirements, and peak demand periods.

What are the benefits of using energy-free or frost-free watering solutions?

Energy-free and frost-free watering solutions reduce energy costs and minimize the risk of freezing, ensuring a reliable water supply.

How can I protect heavy use areas around water points?

Use surface materials like concrete, gravel, or geotextiles, and implement proper drainage design to prevent mud and erosion.

Why is water quality management important for cattle health?

Water quality management is crucial to prevent waterborne illnesses and ensure cattle consume safe, clean water.

How can I maintain my cattle water system?

Regular maintenance includes cleaning, inspecting parts, and preventing freezing, as well as addressing any issues promptly.

What are the costs associated with cattle watering systems?

Costs include initial installation, energy and maintenance expenses, but also long-term benefits like improved cattle health and productivity.

What are the best cattle waterers available in the market?

Top-rated cattle waterers include Ritchie Omni Fount, Little Giant Automatic Animal Waterer, and Miraco Mirafount, among others.

Conclusion of: Cattle Water Systems

Why “Cattle Water” deserves system-level planning

Cattle Water is not just “a trough in a pasture”—it’s a daily production input that can quietly cap performance if flow, access, cleanliness, or winter reliability are weak. A good Cattle Water system starts with planning the water source, estimating peak demand, then matching storage, pipeline capacity, and drinking space so cattle can drink when they want (not when the tank finally refills). Treat your watering layout like you would fencing or feed logistics: sized for today, expandable for tomorrow, and easy to maintain in all seasons NRCS Planning Guide for Livestock Watering

How Cattle Water intake changes across classes and seasons

Cattle Water needs rise and fall with body weight, lactation, diet dry matter, and—most importantly—weather. In practical terms, the “right” design target is rarely the annual average; it’s the hot-day peak and the cold-day reliability. If you build only for mild conditions, cattle may face crowding at water, slower refill, and wider intake swings that can show up as uneven gains, reduced milk, or more health stress. Start your design by estimating daily requirements for the heaviest-demand class you manage Water Requirements for Beef Cattle (University of Nebraska–Lincoln Extension)

A field rule-of-thumb to estimate daily Cattle Water demand

To quickly estimate Cattle Water demand, many producers use a weight-based rule-of-thumb and then adjust for temperature and lactation. This gets you close enough to size trough access and supply lines before you fine-tune with local conditions. The key is to “design for the day it matters,” not the day it’s easy—because the risk is usually not that cattle drink too much, but that they can’t drink enough fast enough when heat, dust, or high dry-matter rations push intake up Weather and Water Intake in Beef Cattle (South Dakota State University Extension)

Peak-hour thinking: Cattle Water is a flow problem, not only a volume problem

Cattle Water systems fail most often at peak demand: hot afternoons, immediately after feed delivery, or when socially dominant animals guard access points. Even if your daily gallons look fine, the herd can still under-consume if the refill rate can’t keep troughs “drink-ready” or if drinking space is tight. A strong design habit is to think in “who drinks at the same time” and “how quickly the facility recharges,” then build margin for heat waves and growth in herd size Heat Stress Guidance and Water Access (North Dakota State University Extension)

A practical design target: water the whole herd within a short window

Many Cattle Water design standards use a “short-window” approach because cattle often drink in bouts rather than evenly all day. A widely used guideline is to design so the system can water all livestock in the grazing unit within about two hours, which forces you to size both drinking access and delivery rate for realistic peak use. This approach also makes winter troubleshooting easier because you’ll see problems (low flow, frozen valves, air locks) quickly instead of discovering them after cattle have been shorted for hours NRCS Conservation Practice Standard 614 (Watering Facility – OK)

Flow-rate math you can actually use for Cattle Water planning

For Cattle Water “drinking facilities” that depend on quick recharge, a practical standard is to size flow so it can supply about 2.0 gallons per minute per “drinking head” (the number of animals that can drink at the same time, based on available drinking space). That means your trough perimeter and animal access directly affect the gallons-per-minute you must deliver. When you treat flow as a design spec—along with gallons per day—you build systems that stay functional during heat spikes and don’t turn into a daily refill crisis NRCS 614 Flow Rate Guidance (2.0 GPM per Drinking Head)

Choosing the right facility type for your Cattle Water system

Not every Cattle Water point needs the same “muscle.” Some sites are best served by larger combination drinking-and-storage tanks (buffer volume plus access), while others can be small drinking facilities that refill fast from a dependable pipeline. This distinction matters because it changes how you size trough capacity, how sensitive you are to short outages, and how you manage winter freeze risk. If you’re rotationally grazing, consider whether portability or multiple smaller sites improves distribution enough to justify added plumbing complexity NRCS Conservation Practice Standard 614 (Watering Facility – NHCP)

Minimum storage: what to do when Cattle Water interruptions happen

Cattle Water systems should anticipate real-life problems: a float sticks, a valve leaks, a line freezes, or a pump trips. Where a malfunction is not immediately obvious, building in storage (or multiple water points) can prevent animals from being shorted. Some standards call for days of storage depending on power source and reliability, while other situations allow smaller minimums when facilities are checked daily. The point is not to overbuild blindly; it’s to match storage to the consequence of failure at your site Overview of NRCS Water System Standards (Farm Progress)

Trough sizing starts with access: don’t “tank-size” your way out of poor Cattle Water space

Cattle Water trough sizing is often discussed as gallons, but access is the first limiter. If only a few animals can drink comfortably, a huge tank still creates waiting lines and bully pressure. In summer, many herds need more linear drinking space to prevent crowding and keep subordinate cattle drinking normally. When you’re designing, think “How many heads can drink at once?” and “Can calves reach safely?” before you decide whether you need one large trough or several smaller ones Waterer Space Guidance (SDSU Extension)

Linear inches per head: an easy checkpoint for Cattle Water access

A simple way to audit Cattle Water access is to measure linear inches of drinkable perimeter and compare it to your head count. Under heat stress, limited access can become a hidden driver of reduced intake because cattle drink more often and may try to drink simultaneously. Practical recommendations vary by setting, but if you see crowding, pushing, or a few animals “owning” the water, treat it as a design problem—not a behavior problem—and add access points or increase trough perimeter Trough Space and Access Under Heat Stress (NDSU Extension)

Perimeter-based standards that help size Cattle Water facilities

Some watering facility standards provide perimeter and drinking-space guidance by species, which is useful when you’re building permanent infrastructure. These tables help you translate “herd size” into “how much accessible edge” you must provide, which then feeds into the “drinking head” count for flow-rate sizing. If you’re expanding a pasture system, use these benchmarks as a starting point and then adjust based on your cattle type, terrain, and whether you run mixed groups (cows, calves, bulls) NRCS 614 Drinking Space Requirements Table (OK)

Supply lines and pressure: the backbone of reliable Cattle Water

Cattle Water delivery is only as good as the pipeline that feeds it. Undersized pipe, long runs with too many elevation changes, and poorly protected shallow installs can all show up as slow refill, air locks, or freeze damage. Pipeline design standards emphasize adequate pressure ratings, appropriate depth of cover, valves suited to the working pressure, and features that reduce hydraulic problems. If you’re unsure, oversizing pipe and planning clean valve access is often cheaper than fighting chronic low-flow for years NRCS Conservation Practice Standard 516 (Livestock Pipeline)

Backflow prevention and water source protection for Cattle Water safety

When Cattle Water systems connect to wells, rural water, or shared sources, backflow prevention is not an “extra”—it’s a basic safeguard. A vacuum event, a siphon condition, or a submerged hose can pull contaminants back toward the source if protections aren’t in place. Standards often call for approved backflow devices or a properly sized air-gap where contamination risk exists. This is especially important when you use chemical cleaning, frost-control setups, or mixed-use plumbing on a farmstead Backflow and Air-Gap Guidance in NRCS 516 (Livestock Pipeline)

Testing your Cattle Water source: treat it like a yearly “health check”

Cattle Water quality issues can be invisible until performance slips—so routine testing is a smart habit, especially for private wells and surface sources. Annual checks commonly include bacteria indicators, nitrates, total dissolved solids (TDS), and pH, plus any local contaminants your area is known for. If you flood, repair a well, notice odor or taste changes, or bring new water online, test immediately. Use certified labs when possible so results are actionable and comparable year to year Guidelines for Testing Well Water (CDC)

What “TDS” and salinity can do to Cattle Water intake

Cattle Water with elevated salinity (high TDS) can reduce palatability, change intake patterns, and sometimes contribute to digestive upset or reduced performance—especially in sensitive classes like pregnant or lactating cows. TDS can also fluctuate seasonally, particularly in shallow groundwater and surface sources, so a one-time “good test” doesn’t guarantee the same quality later. If you’re using ponds, low-flow creeks, or shallow wells, build testing into your management calendar and treat sudden intake changes as a possible water-quality signal Livestock Water Quality and TDS (Montana State University Extension)

Nitrates: a Cattle Water risk that overlaps with feed risk

Cattle Water nitrates matter most because the total nitrate load comes from both water and feed, and the risk can climb during drought, heavy fertilization, or contamination events. Even when cattle appear fine, chronic exposure can hurt reproduction or growth depending on dose and circumstances. The practical takeaway: if you’ve had forage nitrate concerns (sorghum, corn stalks, stressed annuals), test your water too, and work with your veterinarian or extension to interpret combined exposure—especially for pregnant cows and fast-growing replacements Nitrate Problems in Livestock Feed and Water (University of Missouri Extension)

A quick nitrate benchmark you can reference when evaluating Cattle Water tests

If you want a simple checkpoint for Cattle Water nitrate results, some livestock guidance documents recommend avoiding water above specific nitrate thresholds and seeking professional advice if results are elevated—particularly when cattle are also consuming higher-nitrate feeds. While “safe” can vary with diet and adaptation, using a credible fact sheet can help you ask the right questions and decide whether to dilute, change sources, or modify feeding strategy until conditions improve Nitrate in Drinking Water Fact Sheet (Nebraska DEE)

Sulfates and sulfur: why Cattle Water minerals deserve attention

Cattle Water can carry sulfate levels high enough to affect performance, mineral status (notably copper), and in some cases contribute to polioencephalomalacia (PEM) risk—especially when combined with high-sulfur feeds like some distillers grains. This is one of those issues where “the water looks fine” isn’t reassuring, because the problem is chemical, not visual. If you’re seeing unexplained loose manure, reduced gains, or mineral issues, testing water sulfate and reviewing total dietary sulfur can be a high-return troubleshooting step Managing Sulfur in Beef Cattle Feed and Water (University of Minnesota Extension)

Cleanliness: the simplest upgrade to daily Cattle Water intake

Cattle Water troughs can accumulate sediment, manure splash, algae, and bacterial contamination faster than many producers expect—especially during warm months, dusty conditions, or heavy traffic periods. A practical approach is scheduled debris removal plus periodic disinfection, along with placement choices that reduce heat and contamination (such as limiting leaf drop and managing shade). Clean water supports consistent intake, and consistent intake supports consistent performance. If you want one “low-cost, high-impact” habit, make trough cleaning a routine, not a rescue mission Maintaining a Clean Water Trough for Cattle (University of Georgia)

Algae control that fits real farms and real Cattle Water routines

Cattle Water algae is rarely a one-time fix; it’s a management loop. Sunlight, nutrients, and warm trough surfaces encourage algae growth, so strategies often combine physical cleaning with practical prevention. Some extension guidance discusses how to reduce algae buildup through routine scrubbing, thoughtful trough siting, and—when appropriate—carefully dosed treatments that consider tank volume and livestock sensitivity. The best approach is the one you can repeat weekly without creating new risks (like corrosion, cord hazards, or copper issues in mixed-species farms) Controlling Algae in Livestock Water Tanks (NC State Extension)

Placement matters: Cattle Water is a grazing distribution tool

Cattle Water location influences where cattle spend time, where they loaf, and where they overgraze. In managed grazing, better water placement can improve pasture utilization and reduce erosion and nutrient loading in sensitive areas. Studies and on-farm evaluations have shown that providing alternative water points can reduce time cattle spend in streams and cut streambank damage, while also improving how evenly cattle use a paddock. If you’re trying to fix “one corner always grazed, one corner always ignored,” water placement is a powerful lever Pumps and Watering Systems for Managed Beef Grazing (University of Missouri Extension)

Winter basics: your Cattle Water plan should include freeze scenarios

Cattle Water winter failures tend to be predictable: exposed floats freeze, shallow lines ice up, overflows create mud, and daily ice-breaking becomes a labor trap. Start by listing your most likely freeze points (valves, bowls, risers, hose connections), then choose a strategy that matches your site: electricity available or not, wind exposure, distance from buildings, and how often you can physically check tanks. A winter plan is not just “keep water liquid”—it’s “keep access safe, refill reliable, and footing stable” Winter Watering for Livestock (West Virginia University Extension)

Low-tech winter freeze control for Cattle Water systems

If you need low-tech Cattle Water freeze control, focus on reducing heat loss and breaking surface ice without turning chores into a full-time job. Common approaches include wind protection, insulation concepts (where feasible), and surface agitation techniques that slow ice formation. Also plan where meltwater and overflow will go so you don’t create a frozen mud rink around the trough. Winter is when “small design details” matter most—like having a drain, having a stable pad, and not placing your only water point where drifting snow blocks access Winter Freeze Management Ideas (WVU Extension)

When electricity is available: heated Cattle Water without creating hazards

Electric heat can make Cattle Water systems dramatically easier in winter, but only if you treat cords, heaters, and outlets as safety-critical equipment. Keep animals away from cords, protect plugs from moisture, and avoid makeshift extension-cord setups that become fire hazards in dusty, damp environments. Plan for the day a tank runs low: heaters that operate “dry” can be dangerous, so daily checks still matter. If you’re installing heated units, design for maintenance access so you can repair quickly in the coldest week of the year Electrical Safety Considerations (South Dakota State University Extension)

Energy-free and geothermal-style options for winter Cattle Water reliability

Where electricity isn’t practical, Cattle Water can still be winter-reliable using designs that leverage ground heat, protect risers and floats, and reduce exposure to wind. Energy-free and geothermal-style concepts can work well, but they depend on correct installation and enough animal use to keep the system functioning as intended. Some setups also use controlled continuous-flow strategies—effective, but only if overflow is managed to prevent mud and icing. The best “no-electric” winter system is the one that matches your climate, cattle numbers, and your willingness to maintain it Winter Watering Options (University of Kentucky Master Grazer)

Freeze-proof pipelines: protect Cattle Water by protecting the line

Cattle Water reliability in winter often comes down to pipeline decisions made in summer: depth, slope, valve placement, and how you handle undulating terrain that can trap air or create low spots that freeze. Planning guidance highlights field constraints (shallow bedrock, wetlands, unstable slopes) and encourages verifying feasibility early—because rerouting a line or adjusting a tank site is far cheaper before you trench and bury pipe. If you’re building new, invest time up front in layout and serviceability Frost-Free Pipeline Planning Considerations (NRCS)

Daily checks and a simple maintenance routine for Cattle Water systems

Cattle Water systems last longer and perform better when maintenance is boring and consistent. Check refill rate, look for leaks, confirm floats shut off properly, remove debris, and watch cattle behavior (crowding, pushing, waiting) as a real-time indicator of access problems. In winter, add a quick “freeze-point audit” (valves, bowls, risers, and footing). A short daily checklist beats emergency repairs—because cattle don’t stop needing water when the weather turns, the pump fails, or a float sticks open Operation and Protection Notes in NRCS 614 (Watering Facility)

Final thought

The best Cattle Water system is the one you rarely have to think about: cattle can drink without crowding, troughs refill fast during peaks, water stays clean, and winter doesn’t turn watering into a daily battle. If you’re upgrading, prioritize (1) access space, (2) flow rate at peak demand, (3) water quality testing, and (4) a winter strategy that matches your site. Build those four well, and everything else—tank size, layout, and hardware choices—gets easier to optimize over time UNL Extension: Water Requirements and Practical Management

Sources & References

The Cattle Water recommendations above are grounded in extension and NRCS design guidance so you can cross-check numbers and adapt them to your herd and climate

- Livestock Waterers & Tanks at Tractor Supply Co.

- 5 Best Cattle Waterers: FOUND and Tested for Your Herd

- 7 Best Livestock Waterers for Animal Hydration That Old Farmers

- Cobett Company | Automatic Cattle & Livestock Waterers

- Cattle Waterers & Livestock Waterers – Johnson Concrete Products

- Miraco Livestock Waterers – am.gallagher.com

- Water Systems for Cattle: New Technologies Ahead

- High-Quality Livestock Waterers | Blue River Waterers

- Livestock Waterers | Livestock Equipment | Livestock Supplies

- 5 Best Cattle Waterer – Reviews & Guide | Farming Base

- NRCS Practice Standard 614 (Watering Facility)

- NRCS Planning Guide for Livestock Watering

- NRCS 614 Watering Facility (OK) – flow, access, and storage concepts

- NRCS 614 Watering Facility (NHCP)

- NRCS 516 Livestock Pipeline

- University of Nebraska–Lincoln Extension: Water Requirements for Beef Cattle

- South Dakota State University Extension: Weather and Water Intake

- North Dakota State University Extension: Heat Stress and Water Access

- University of Georgia: Maintaining a Clean Water Trough for Cattle

- NC State Extension: Controlling Algae in Livestock Water Tanks

- University of Missouri Extension: Pumps and Watering Systems for Managed Beef Grazing

- West Virginia University Extension: Winter Watering for Livestock (PDF)

- University of Kentucky Master Grazer: Winter Watering of Livestock

- Montana State University Extension: Livestock Water Quality (TDS and more)

- University of Missouri Extension: Nitrate Problems in Livestock Feed and Water

- University of Minnesota Extension: Managing Sulfur in Beef Cattle Feed and Water

- CDC: Guidelines for Testing Well Water

- US EPA: Protect Your Home’s Water (private wells)