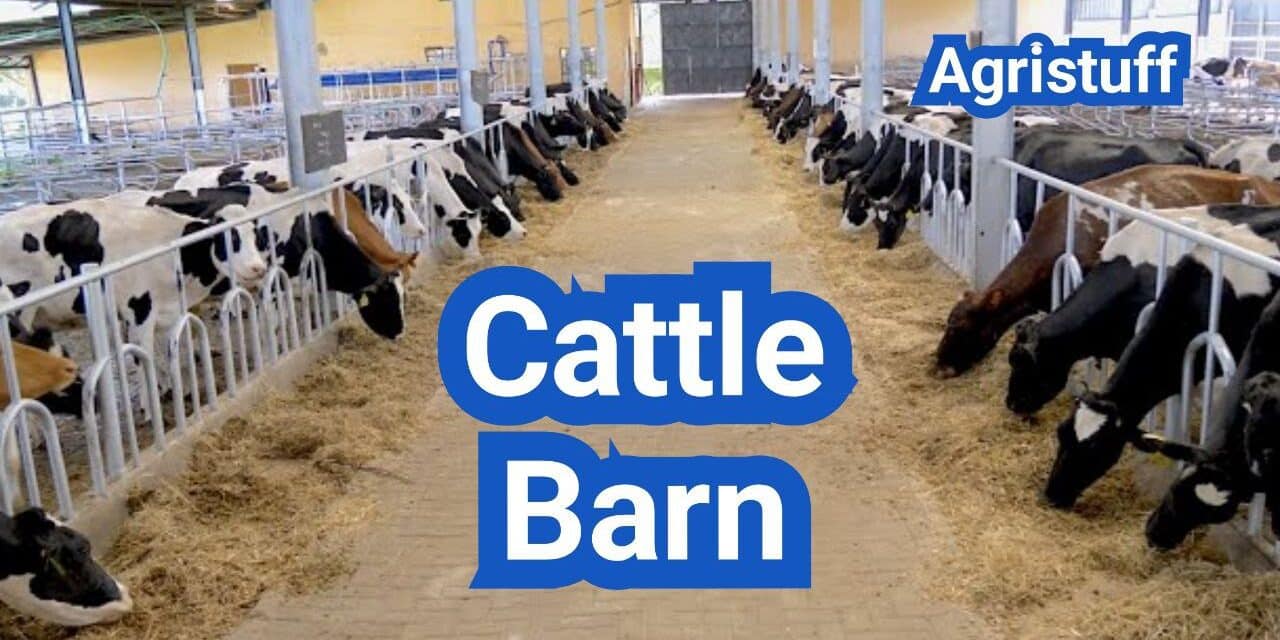

A well-designed cattle barn layout is crucial for the health and productivity of livestock. It can make the difference between thriving animals and costly operational issues.

Effective cattle barn design involves careful consideration of several key factors, including ventilation, manure handling, and adherence to fire codes. Proper ventilation helps maintain a healthy environment, while efficient manure handling is essential for both environmental protection and farm productivity.

Designing a small barn for cows that meets these requirements can be challenging, but it is essential for the well-being of the animals and the success of the farm.

Key Takeaways

- Proper ventilation is crucial for maintaining a healthy environment in a cattle barn.

- Efficient manure handling is essential for environmental protection and farm productivity.

- Adherence to fire codes is vital for the safety of both animals and farm personnel.

- A well-designed barn layout can improve the health and productivity of livestock.

- Careful planning is necessary to create an effective cattle barn design.

Understanding Modern Cattle Barn Requirements

As the agricultural industry continues to evolve, the requirements for cattle barns have become more sophisticated, focusing on animal comfort and productivity. Different types of livestock require shelter for various reasons, and understanding these needs shapes your barn design decisions.

What Defines a Cattle Barn

A cattle barn is more than just a shelter; it’s a critical component of livestock management. It provides protection from the elements, enhances animal welfare, and improves operational efficiency. The design and construction of a cattle barn must consider factors such as ventilation, manure handling, and fire safety codes.

The Evolution of Cattle Barns in the United States

Over the years, cattle barns in the U.S. have undergone significant transformations. From traditional structures to modern, technologically advanced facilities, the evolution has been driven by the need for better animal welfare, increased productivity, and environmental sustainability.

Key Functions of Today’s Livestock Housing

Modern livestock housing, including cattle barns, serves multiple purposes. It not only provides shelter but also facilitates efficient feeding, watering, and manure management. The design must balance animal comfort with operational practicality.

| Function | Description | Benefits |

|---|---|---|

| Ventilation | Proper airflow to maintain air quality | Improved animal health, reduced disease risk |

| Manure Handling | Efficient removal and storage of manure | Reduced environmental impact, improved barn cleanliness |

| Feeding and Watering | Accessible feeding and watering systems | Enhanced animal welfare, increased productivity |

Understanding these key functions and how they contribute to the overall efficiency and sustainability of cattle operations is crucial for designing effective cattle barns.

Planning Your Cattle Barn Project

Planning a cattle barn project requires careful thought and consideration of multiple elements. A well-designed barn is crucial for the health, productivity, and overall success of your livestock operation.

Determining Herd Size Requirements

The first step in planning your cattle barn is determining the appropriate herd size. This decision will influence the size of your barn, the layout, and the overall cost of the project. Factors to consider include available land, financial resources, and market demand for your products.

A general rule of thumb is to allocate sufficient space per animal to ensure their comfort and health. Overcrowding can lead to stress and decreased productivity.

| Animal Type | Recommended Space per Animal |

|---|---|

| Cow | 60-80 square feet |

| Calf | 20-30 square feet |

| Bull | 100-120 square feet |

Climate Considerations for Your Region

Climate plays a significant role in cattle barn design. Different regions have unique climate challenges that must be addressed to ensure the barn provides a comfortable environment for the livestock.

Regional Climate Factors:

- Temperature extremes

- Precipitation levels

- Wind patterns

For example, in hotter climates, barns may need to be designed with enhanced ventilation and shading to keep the animals cool.

Operational Goals: Dairy vs. Beef Production

Your operational goals will significantly influence the design of your cattle barn. Whether you are raising cattle for dairy or beef production will affect the layout, equipment, and overall functionality of the barn.

Dairy Production: Requires milking facilities, specific feeding systems, and often more complex ventilation systems.

Beef Production: May focus more on feeding and growth facilities, with different requirements for space and equipment.

Understanding your operational goals will help you design a barn that meets your specific needs and enhances your operation’s efficiency.

Types of Cattle Barns for Different Operations

Different cattle operations require distinct types of barns to optimize efficiency and animal welfare. The design and configuration of a cattle barn can significantly impact the health and productivity of the cattle, as well as the overall profitability of the operation.

Small Cattle Barns for Limited Operations

For small-scale cattle operations or hobby farms, a compact and efficient barn design is crucial. Small cattle barns are ideal for limited operations, providing the necessary shelter and facilities without excessive costs. These barns can be designed to accommodate a few head of cattle, with considerations for feeding, watering, and manure handling.

When planning a small cattle barn, it’s essential to optimize the use of space. This can include incorporating multi-functional areas and selecting equipment that serves more than one purpose.

Beef Cattle Barn Configurations

Beef cattle barns are designed with specific configurations to meet the needs of beef production. These barns often feature open designs to allow for easy access and ventilation. The layout may include pens or paddocks for segregating cattle based on age, size, or feeding requirements.

Beef cattle barn configurations can vary, but they typically include areas for feeding, watering, and handling cattle. The design should also consider the flow of cattle through the facility to minimize stress and improve handling efficiency.

Dairy Cattle Housing Solutions

Dairy cattle housing requires specialized designs to ensure the health and productivity of the dairy herd. Dairy barns are typically more enclosed than beef cattle barns, with a focus on providing a comfortable environment for milk production. Features may include stall arrangements, feeding systems, and milking facilities.

The design of dairy cattle housing should prioritize cow comfort, with adequate space for resting, feeding, and milking. Ventilation and cooling systems are also critical in dairy barns to mitigate heat stress during warmer months.

Monoslope Barn Designs and Benefits

Monoslope barns are a popular choice for cattle operations due to their simplicity and effectiveness. Characterized by a single-sloping roof, these barns offer excellent ventilation and can be more energy-efficient than traditional designs. The monoslope design allows for natural airflow, reducing the need for mechanical ventilation systems.

The benefits of monoslope barn designs include improved climate control, reduced construction costs, and enhanced animal comfort. These barns can be adapted for various cattle operations, from beef to dairy production.

| Barn Type | Key Features | Benefits |

|---|---|---|

| Small Cattle Barns | Compact design, multi-functional areas | Cost-effective, efficient use of space |

| Beef Cattle Barns | Open design, pens or paddocks | Easy access, improved ventilation |

| Dairy Cattle Housing | Enclosed design, stall arrangements, milking facilities | Enhanced cow comfort, improved milk production |

| Monoslope Barns | Single-sloping roof, natural ventilation | Improved climate control, energy efficiency |

Building Materials and Construction Options

When it comes to constructing a cattle barn, the choice of building materials and construction methods is crucial for ensuring durability and functionality. The right materials and construction techniques can significantly impact the barn’s overall performance, affecting factors such as animal comfort, operational efficiency, and long-term maintenance costs.

Steel Livestock Buildings: Advantages and Considerations

Steel livestock buildings have gained popularity due to their durability and low maintenance requirements. Steel structures can withstand harsh weather conditions and are resistant to pests and diseases that can affect traditional wood structures. Additionally, steel buildings can be designed to be highly customizable, allowing for flexible layouts that can accommodate different cattle operations.

However, there are considerations to keep in mind when opting for steel livestock buildings. The initial cost can be higher compared to traditional materials, and proper insulation is crucial to maintain a comfortable temperature inside the barn. Furthermore, the potential for corrosion should be addressed through the use of protective coatings or galvanized steel.

Prefabricated Cattle Barn Kits

Prefabricated cattle barn kits offer a convenient and often cost-effective solution for farmers. These kits usually include pre-cut and pre-drilled components that can be quickly assembled on-site. The primary advantage of prefabricated kits is the reduced construction time, allowing farmers to get their operations up and running sooner.

When considering prefabricated cattle barn kits, it’s essential to evaluate the quality of the materials provided and the design flexibility offered by the manufacturer. Some kits may be highly customizable, while others may have more limited options.

Traditional Wood Frame Construction

Traditional wood frame construction remains a popular choice for cattle barns due to its aesthetic appeal and the availability of materials. Wood is a natural insulator and can provide a comfortable environment for cattle. Properly maintained wood structures can last for many years, although they may require more upkeep than steel structures.

One of the key considerations with traditional wood frame construction is the potential for damage from pests and decay. Regular maintenance, including inspections and repairs, is necessary to ensure the longevity of the structure.

Fundamental Cattle Barn Design Principles

Effective cattle barn design hinges on several fundamental principles that ensure the welfare of the animals and the efficiency of the operation. These principles are crucial for creating a functional and productive environment for livestock.

Space Requirements Per Animal

One of the critical aspects of cattle barn design is allocating sufficient space per animal. The space requirements vary depending on the age, size, and type of cattle. For instance, dairy cows require more space than beef cattle due to their need for milking and feeding facilities. A general rule of thumb is to provide enough space for cattle to stand up, lie down, and move around comfortably.

For example, a mature dairy cow may require about 68 to 72 square feet of space, while younger animals need less. Proper spacing helps reduce stress among the animals, which can lead to improved health and productivity.

Traffic Flow Considerations

Traffic flow within the cattle barn is another vital consideration. The layout should facilitate easy movement of animals, personnel, and equipment. This includes designing alleys and passageways that are wide enough for cattle to move comfortably without congestion.

A well-planned traffic flow helps in reducing the risk of injury to both animals and handlers. It also enhances the overall efficiency of the operation by streamlining tasks such as feeding, milking, and manure handling.

Feeding and Watering Station Placement

The strategic placement of feeding and watering stations is essential for the health and well-being of the cattle. These stations should be easily accessible, clean, and designed to minimize waste and contamination.

For instance, feeding areas should be positioned to prevent dominant animals from monopolizing the feed, ensuring that all cattle have adequate access to nutrition. Watering stations should be placed in a way that they are easily accessible and not prone to freezing in colder climates.

By carefully considering these fundamental principles, farmers and builders can create cattle barns that are not only functional but also promote the health and productivity of the livestock. Effective design is key to a successful and sustainable livestock operation.

Creating Effective Cattle Barn Layouts

Designing an effective cattle barn layout is crucial for the welfare of the animals and the overall efficiency of the operation. A well-designed layout can improve animal comfort, reduce labor costs, and enhance the overall productivity of the farm.

Open vs. Closed Barn Designs

The choice between open and closed barn designs depends on several factors, including climate, available resources, and the specific needs of the cattle operation. Open barn designs offer better natural ventilation and can be more cost-effective, while closed barn designs provide more control over the internal environment.

Open Barn Designs: These are ideal for mild climates where natural ventilation is sufficient. They offer reduced construction costs and can provide a more natural environment for the cattle.

Closed Barn Designs: These are better suited for extreme climates where more control over temperature and humidity is necessary. They can provide a more consistent environment, which can be beneficial for certain operations.

Optimizing Alley Widths and Pen Configurations

The width of alleys and the configuration of pens are critical factors in cattle barn design. Properly designed alleys and pens can improve animal flow, reduce stress, and enhance the overall efficiency of the operation.

| Alley Width | Recommended Width | Benefits |

|---|---|---|

| Feeding Alley | 12-14 feet | Ease of access for feeding equipment |

| Manure Alley | 10-12 feet | Facilitates manure removal |

| Animal Traffic Alley | 8-10 feet | Reduces animal stress |

Equipment Access Planning

Effective equipment access planning is essential for the smooth operation of a cattle barn. This includes considering the size and type of equipment that will be used, as well as the frequency of access required.

- Ensure adequate space for equipment maneuverability

- Plan for regular maintenance access

- Consider the flow of equipment through the barn

Implementing Cattle Handling Facilities

Cattle handling facilities are a crucial component of any cattle barn. Well-designed handling facilities can reduce animal stress, improve safety for workers, and increase the efficiency of cattle handling operations.

Key considerations: Include features such as crowding pens, squeeze chutes, and sorting areas. Ensure that all handling facilities are designed with animal welfare and safety in mind.

Essential Ventilation Systems for Cattle Barns

Proper ventilation systems are essential for ensuring the well-being of cattle and the overall efficiency of barn operations. Effective ventilation helps maintain air quality, regulate temperature, and reduce moisture, all of which are critical for the health and productivity of the cattle.

Naturally Ventilated Barn Systems

Naturally ventilated barn systems rely on natural airflow to ventilate the barn. This is achieved through the design of the barn, including the use of open sides, ridge vents, and careful orientation to prevailing winds. Naturally ventilated dairy barns are particularly popular due to their energy efficiency and simplicity.

The effectiveness of naturally ventilated systems depends on factors such as climate, barn orientation, and the presence of obstructions. In regions with mild climates, natural ventilation can be highly effective, reducing the need for mechanical ventilation systems.

Cross-Ventilated Barn Designs

Cross-ventilated barn designs enhance natural ventilation by allowing air to enter from one side of the barn and exit from the other. This design takes advantage of wind pressure to improve airflow, making it particularly effective in areas with consistent wind patterns.

Key features of cross-ventilated barns include large openings on both sides and often a ridge vent to facilitate air exchange. This design helps to maintain a consistent internal environment, reducing temperature fluctuations and moisture buildup.

Tunnel Ventilation Implementation

Tunnel ventilation involves the use of large fans to pull air through the barn, typically from one end to the other. This system is particularly effective in barns with high animal densities or in climates where natural ventilation is insufficient.

Tunnel ventilation systems are often used in conjunction with other ventilation methods to enhance cooling during hot weather. The fans create a significant airflow that helps to reduce heat stress in cattle.

Ridge Vent Sizing and Placement

Ridge vents are a critical component of many ventilation systems, allowing warm air to escape from the barn. Proper sizing and placement of ridge vents are essential for effective ventilation.

The size of the ridge vent should be calculated based on the barn’s size and the ventilation needs of the animals. Placement at the highest point of the roof ensures that warm air can escape efficiently, improving overall ventilation.

By understanding and implementing these ventilation systems, cattle barn operators can significantly improve the health and productivity of their animals, while also enhancing the overall efficiency of their operations.

Seasonal Ventilation Management Strategies

Effective seasonal ventilation management is crucial for maintaining a healthy cattle barn environment throughout the year. Ventilation needs vary significantly with the seasons, requiring adjustments to maintain a comfortable and healthy environment for the cattle.

Winter Ventilation for Moisture Control

During winter, the primary concern is moisture control. Cold air has a lower capacity to hold moisture, and if not properly ventilated, barns can become humid, leading to condensation and frost buildup. Proper winter ventilation involves removing moist air from the barn while introducing dry, cold air. This can be achieved through a combination of natural and mechanical ventilation systems.

Key strategies include:

- Using ridge vents to allow moist air to escape

- Employing controlled intake vents to manage airflow

- Minimizing drafts at animal level to prevent discomfort

Summer Cooling Systems for Heat Stress Prevention

In the summer, the focus shifts to preventing heat stress. High temperatures and humidity can severely impact cattle health and productivity. Effective summer cooling systems are essential for maintaining a comfortable environment.

Some effective strategies for summer cooling include:

- Utilizing tunnel ventilation to create a cooling effect

- Installing sprinkler systems to lower temperatures

- Maximizing natural ventilation through open sidewalls and roof vents

Sidewall Curtain Design and Operation

Sidewall curtains play a crucial role in both winter and summer ventilation. In the winter, they can be closed to retain warmth, while in the summer, they can be opened to facilitate natural ventilation. The design and operation of these curtains are critical for effective seasonal ventilation management.

When designing sidewall curtains, consider factors such as:

- Material durability and insulation properties

- Automated control systems for easy operation

- Seal integrity when closed to prevent air leaks

By implementing these seasonal ventilation management strategies, cattle barn operators can ensure a healthier and more comfortable environment for their animals, regardless of the outside weather conditions.

Mechanical Ventilation Components and Maintenance

Effective mechanical ventilation is crucial for maintaining a healthy environment in cattle barns. Mechanical ventilation systems are designed to remove stale air and bring in fresh air, helping to regulate temperature and humidity levels.

Fan Sizing and Placement Guidelines

Proper fan sizing and placement are critical for the effective operation of mechanical ventilation systems. Fans must be sized correctly to provide adequate airflow for the barn’s volume and layout. Incorrect fan sizing can lead to inadequate ventilation, resulting in heat stress and reduced animal comfort.

- Consider the barn’s dimensions and the number of animals when sizing fans.

- Place fans to maximize airflow distribution, avoiding dead zones.

- Ensure fans are positioned to minimize recirculation of stale air.

Ventilation Controller Systems

Ventilation controller systems are sophisticated devices that monitor and adjust ventilation rates based on temperature, humidity, and other environmental factors. These systems help optimize ventilation for animal comfort and energy efficiency. Advanced controllers can integrate with other barn systems, such as feeding and lighting, to create a comprehensive environmental management system.

- Select a controller that can accurately monitor relevant environmental parameters.

- Ensure the system can control multiple fans or ventilation stages.

- Consider integration capabilities with other barn management systems.

Maintenance Schedule for Optimal Performance

Regular maintenance is essential for the longevity and effectiveness of mechanical ventilation systems. A well-planned maintenance schedule helps prevent unexpected failures and ensures consistent performance. A typical maintenance schedule includes regular cleaning of fans and vents, inspection of electrical components, and verification of system controls.

- Clean fans and vents regularly to prevent dust buildup.

- Inspect electrical connections and controls for signs of wear or damage.

- Test the system periodically to ensure it’s functioning as expected.

By focusing on these key aspects of mechanical ventilation, cattle barn operators can create a healthier, more comfortable environment for their animals, ultimately enhancing the overall efficiency and productivity of their operations.

Designing Effective Manure Handling Systems

Cattle barn operators must prioritize effective manure handling to maintain a clean and safe environment for their animals. A well-designed manure handling system is crucial for the overall health and productivity of the cattle operation.

Scrapers vs. Flush Systems Comparison

When it comes to manure handling, two primary systems are used: scrapers and flush systems. Scraper systems involve mechanical scrapers that remove manure from the barn alleys, while flush systems use water to flush out the manure. The choice between these systems depends on several factors, including the size of the operation, water availability, and labor costs.

Scraper systems are often preferred for their ability to handle large volumes of manure with minimal water usage. However, they require regular maintenance to ensure the scrapers remain in good working condition. Flush systems, on the other hand, can be more effective in certain climates and barn designs, but they require significant water resources.

Alley Slope Requirements for Proper Drainage

Proper alley slope is critical for effective manure handling, regardless of whether a scraper or flush system is used. The alley slope ensures that manure and wastewater flow towards the collection area, reducing the risk of manure accumulation and associated health risks.

The ideal alley slope can vary depending on the barn design and manure handling system. Generally, a slope of 3-5% is recommended to facilitate proper drainage without causing erosion or discomfort to the animals.

Automated Manure Removal Solutions

Automated manure removal systems offer a convenient and efficient solution for cattle barn operators. These systems can significantly reduce labor costs and improve the overall cleanliness of the barn.

Automated systems can be integrated with both scraper and flush systems, allowing for flexible design options. They often include features such as programmable timers and sensors to optimize manure removal based on the barn’s specific needs.

By investing in a well-designed manure handling system, cattle barn operators can improve animal health, reduce environmental impact, and increase operational efficiency.

Manure Storage and Safety Considerations

The importance of proper manure storage cannot be overstated, as it directly impacts the safety and efficiency of cattle operations. Manure storage facilities are a crucial component of cattle barn design, requiring careful planning to mitigate potential hazards.

Storage Facility Options and Sizing

Manure storage facilities come in various forms, including underground pits, above-ground tanks, and lagoons. The choice of storage facility depends on factors such as the size of the operation, available space, and local regulations.

Key Considerations for Sizing Manure Storage Facilities:

- Volume of manure produced

- Frequency of manure removal

- Available storage capacity

- Climate and precipitation patterns

Gas Hazards and Ventilation Requirements

Manure storage areas can accumulate hazardous gases, including ammonia, methane, and hydrogen sulfide. Proper ventilation is essential to prevent the buildup of these gases and ensure a safe working environment.

- Natural ventilation through proper design and orientation

- Mechanical ventilation systems, such as fans and exhaust systems

- Regular monitoring of gas levels

Hydrogen Sulfide Safety Protocols

Hydrogen sulfide is a particularly dangerous gas associated with manure storage, as it can be lethal at high concentrations. Implementing safety protocols is crucial to protect workers and animals.

Key Safety Protocols:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Use of respirators, gas detectors, and other protective gear |

| Ventilation Procedures | Establishing protocols for ventilating manure storage areas before entry |

| Training and Education | Providing workers with training on hydrogen sulfide hazards and safety procedures |

By understanding the importance of manure storage safety and implementing appropriate measures, cattle barn operators can minimize risks and ensure a safe working environment.

Nutrient Management Planning for Cattle Operations

The importance of nutrient management planning cannot be overstated for cattle operations seeking to minimize their environmental footprint. Nutrient management planning is essential for maintaining the sustainability and efficiency of cattle farming.

Regulatory Requirements Overview

Cattle operations must comply with various regulatory requirements related to nutrient management. These regulations are designed to protect water quality and reduce the environmental impact of farming practices.

Key regulatory aspects include:

- Proper handling and storage of manure

- Land application guidelines for nutrients

- Record-keeping and reporting requirements

As stated by the USDA, “A comprehensive nutrient management plan (NMP) is a critical tool for farmers to manage nutrients effectively and protect water quality.”

“A well-designed NMP helps farmers optimize nutrient use, reduce environmental risks, and improve farm profitability.”

Developing a Compliant Nutrient Management Plan

Developing a compliant nutrient management plan involves several key steps:

- Assessing the farm’s nutrient balance

- Identifying potential environmental risks

- Implementing best management practices for nutrient use

- Regularly reviewing and updating the plan

Effective planning requires a thorough understanding of the farm’s operations and the ability to adapt to changing conditions.

Record-Keeping Best Practices

Accurate record-keeping is crucial for a successful nutrient management plan. Records should include details on manure application rates, soil test results, and crop yields.

| Record Type | Description | Frequency |

|---|---|---|

| Manure Application | Details on application rates and methods | Each application |

| Soil Test Results | Soil nutrient levels and pH | Annually |

| Crop Yields | Yield data for nutrient budgeting | After each harvest |

By following these best practices and staying informed about regulatory requirements, cattle operations can develop effective nutrient management plans that support both their business and the environment.

Electrical Systems and Safety in Cattle Barns

The unique conditions of cattle barns demand specialized electrical systems that prioritize safety and corrosion resistance. Cattle barns are challenging environments for electrical systems due to the presence of moisture, manure, and corrosive gases. Ensuring the safety and durability of these systems is crucial for the well-being of both the animals and the personnel working in these facilities.

Corrosion-Resistant Fixture Selection

Selecting the right fixtures for electrical systems in cattle barns is critical. Corrosion-resistant materials should be used to withstand the harsh environment. Fixtures should be designed to minimize dust accumulation and be easy to clean. Some key considerations include:

- Using materials like stainless steel or PVC that can resist corrosion.

- Selecting fixtures with IP67 or higher rating for protection against dust and water.

- Ensuring that all electrical components are accessible for maintenance.

Wiring Considerations for Wet Environments

Wiring in cattle barns must be done with careful consideration of the wet and corrosive environment. Moisture-resistant cables and wiring methods should be employed to prevent electrical failures and safety hazards. Key practices include:

- Using cables with a moisture-resistant jacket.

- Installing wiring in conduit to protect against physical damage and moisture.

- Avoiding wiring methods that can trap moisture or dust.

Grounding and Circuit Protection Requirements

Proper grounding and circuit protection are essential for the safe operation of electrical systems in cattle barns. Grounding systems should be designed to protect against electrical shock and ensure the reliable operation of electrical equipment. Considerations include:

- Implementing a comprehensive grounding system that includes grounding electrodes and bonding.

- Using circuit protection devices like circuit breakers and GFCI outlets to prevent electrical shock.

- Regularly inspecting and maintaining grounding and circuit protection systems.

By focusing on corrosion-resistant fixtures, appropriate wiring practices, and robust grounding and circuit protection, cattle barn operators can ensure the safety and efficiency of their electrical systems. This not only protects the investment in the barn and its equipment but also ensures the health and safety of the animals and personnel.

Fire Prevention and Code Compliance

Cattle barn owners must prioritize fire prevention and code compliance to safeguard their operations. Fire safety is a critical concern in agricultural settings, where the risk of fire can have devastating consequences on both human and animal lives, as well as the business itself.

Agricultural Building Fire Code Requirements

Agricultural buildings, including cattle barns, are subject to specific fire code requirements that vary by jurisdiction. These codes typically address aspects such as building design, construction materials, and the installation of fire detection and suppression systems. Compliance with these regulations is not only mandatory but also crucial for preventing fires and minimizing potential damage.

Key considerations include:

- Using fire-resistant materials in construction

- Ensuring adequate exit routes and emergency access

- Implementing proper storage practices for hay and other combustible materials

Fire Detection and Suppression Systems

Effective fire detection and suppression systems are vital components of a comprehensive fire safety plan. These systems can significantly reduce the risk of fire-related losses by providing early detection and rapid response to potential fires.

Best practices for fire detection and suppression include:

- Installing smoke detectors and heat sensors in strategic locations

- Implementing automatic fire suppression systems, particularly in high-risk areas

- Regularly inspecting and maintaining all fire safety equipment

Emergency Access and Evacuation Planning

In addition to preventive measures, having a well-planned emergency response strategy is crucial. This includes ensuring adequate emergency access to the barn and having a clear evacuation plan in place for both humans and animals.

Key elements of an effective emergency plan include:

- Clearly marked exit routes and emergency exits

- Regular drills and training for farm personnel

- Coordination with local fire departments and emergency services

By prioritizing fire prevention and code compliance, cattle barn owners can significantly reduce the risk of fire-related incidents, protecting their investment, the welfare of their animals, and the safety of their personnel.

Building a Sustainable and Efficient Cattle Barn

Building a sustainable and efficient cattle barn requires careful consideration of several factors, including design, ventilation, manure handling, and fire safety. By incorporating effective cattle barn design ideas and innovative cattle barn designs, farmers can create a healthy environment for their livestock while minimizing environmental impact.

A well-designed cattle barn should prioritize ventilation, manure handling, and fire codes to ensure a safe and healthy environment for the animals. Proper ventilation systems, such as naturally ventilated or cross-ventilated barn designs, can help maintain air quality and reduce the risk of disease. Effective manure handling systems, including scrapers or flush systems, can minimize waste and prevent environmental pollution.

By integrating these elements, farmers can create a sustainable and efficient cattle barn that supports the well-being of their livestock and the environment. This not only enhances the overall productivity of the farm but also contributes to a more environmentally friendly agricultural practice.

FAQ

What is the primary purpose of a cattle barn?

The primary purpose of a cattle barn is to provide shelter and housing for cattle, protecting them from extreme weather conditions and ensuring their overall health and well-being.

What are the key considerations for designing an effective cattle barn?

Key considerations include ventilation, manure handling, fire codes, space requirements per animal, traffic flow, and feeding and watering station placement.

What are the benefits of using steel livestock buildings for cattle barns?

Steel livestock buildings offer durability, low maintenance, and resistance to pests and diseases, making them a cost-effective option for cattle barns.

How do I determine the appropriate herd size for my cattle barn?

Determining herd size involves considering factors such as available space, operational goals, and regional climate conditions.

What are the advantages of monoslope barn designs?

Monoslope barn designs offer improved ventilation, reduced snow load, and increased interior space, making them suitable for various cattle operations.

What are the different types of ventilation systems used in cattle barns?

Common ventilation systems include naturally ventilated barn systems, cross-ventilated barn designs, and tunnel ventilation implementation.

How do I manage manure handling and storage in my cattle barn?

Effective manure handling involves comparing scrapers and flush systems, ensuring proper alley slope for drainage, and implementing automated manure removal solutions.

What are the safety considerations for manure storage facilities?

Safety considerations include managing gas hazards, ventilation requirements, and implementing safety protocols for hydrogen sulfide.

What are the electrical safety considerations for cattle barns?

Electrical safety considerations include selecting corrosion-resistant fixtures, wiring considerations for wet environments, and grounding and circuit protection requirements.

How can I ensure fire prevention and code compliance in my cattle barn?

Ensuring fire prevention and code compliance involves understanding agricultural building fire code requirements, installing fire detection and suppression systems, and planning for emergency access and evacuation.

What are the benefits of integrating smart technology in dairy cattle barns?

Integrating smart technology can improve cattle monitoring, optimize feeding and watering systems, and enhance overall operational efficiency.

How do I develop a compliant nutrient management plan for my cattle operation?

Developing a compliant nutrient management plan involves understanding regulatory requirements, assessing nutrient needs, and implementing best practices for record-keeping.

Conclusion of: Cattle Barn Design

Why Cattle Barn design details matter

A modern Cattle Barn is more than a roof and walls—it’s an engineered environment that protects animal comfort, worker safety, and long-term operating costs. Good airflow reduces moisture, odors, and airborne irritants, while the right layout keeps cows moving calmly and keeps equipment working efficiently. From a compliance standpoint, a Cattle Barn also intersects with manure storage rules, nutrient management expectations, and building/fire requirements that vary by county and state. The goal is a barn that stays dry, breathable, serviceable, and inspectable—without relying on constant “heroic” management to fix design problems after the fact. Purdue Extension: Natural Ventilation for Livestock Housing (AE-97)

Site selection and orientation for wind, sun, and access

Before you draw stalls, place the Cattle Barn on the site so nature helps you. Prevailing winds are your cheapest ventilation fan, but only if the barn has clear “wind access” (no tall trees, grain bins, or sheds creating a wind shadow). Orientation also influences heat load—especially afternoon sun on sidewalls—and affects winter drifting and ice management. A practical Cattle Barn plan also includes all-weather fire access for trucks, a clear turn radius for feed and manure equipment, and enough spacing between buildings to reduce fire spread risk and improve airflow between structures. UW–Madison Extension: Natural Ventilation in Dairy Buildings (site & orientation)

Ventilation targets: think moisture first, then temperature

In a Cattle Barn, the “enemy” in most seasons is moisture: wet bedding, wet alleys, condensation, and humid air that carries ammonia and pathogens. That’s why ventilation planning is often based on minimum air exchange in winter (to control humidity and air quality) and much higher exchange in summer (to reduce heat stress). If you under-ventilate a Cattle Barn in winter to “keep it warm,” you often pay for it with coughing calves, dripping ceilings, and slippery floors. If you under-ventilate in summer, feed intake and production commonly suffer. Use measurable targets—air exchange, humidity, and air speed at animal level—so your ventilation choices are intentional, not guesswork. UW–Madison Extension: Ventilation in Dairy Buildings (air exchange & fan basics)

Natural ventilation architecture: ridge, eaves, and sidewall openings

For many operations, a naturally ventilated Cattle Barn is the best blend of simplicity and resilience—especially when power outages are part of reality. Natural ventilation works when the barn provides large, adjustable inlet area (sidewall curtains or panels), a continuous outlet (ridge opening), and a roof shape that encourages warm, moist air to rise and exit. Problems start when a Cattle Barn is “tightened up” with undersized openings, blocked ridges, or interior obstructions that interrupt crossflow. Keep airflow paths clear, avoid dead corners, and design openings so you can safely “tune” the barn through changing wind, rain, and temperature conditions without creating drafts at cow level. UW–Madison Extension: Natural Ventilation in Dairy Buildings (ridge & curtain guidance)

Mechanical ventilation options when natural flow isn’t enough

Some Cattle Barn footprints—very wide barns, tight sites, or certain climates—need mechanical help for consistent air distribution. Tunnel, cross, or negative-pressure designs can deliver predictable airflow when wind is calm, but they require correct fan/inlet sizing, careful maintenance, and a plan for static pressure and backup power. A mechanically ventilated Cattle Barn should be designed so air actually reaches animal level, not just the rafters. Fans must be protected from corrosive barn air, kept clean, and placed so baffles/air paths prevent “short-circuiting” (fresh air exiting before it mixes through the barn). If you go mechanical, plan for service access and controls you can understand, monitor, and troubleshoot. UW–Madison Extension: Ventilation in Dairy Buildings (fan types, maintenance, efficiency)

Heat stress control: combine air speed with smart cooling

In summer, a Cattle Barn needs both air exchange and air speed where cattle stand and lie. Air speed improves convective cooling and helps remove the heat load animals carry into the resting area. Where humidity allows, many farms pair airflow with targeted soak-and-fan strategies at the feed line, then keep resting areas dry and well-ventilated. The best Cattle Barn heat-stress approach is staged: open the building for natural flow first, then add circulation/cross ventilation, then add cooling at the feed area if needed—while watching that you don’t create wet bedding that backfires on hoof health and hygiene. University of Minnesota Extension: Heat Stress in Dairy Cattle (ventilation & airflow)

Winter strategy: prevent “warm barn syndrome” and keep it breathable

A winter-ready Cattle Barn is not necessarily a warm barn—it’s a dry, breathable barn that manages humidity without blasting animals with drafts. The practical win is stable air quality: avoid the cycle of closing everything tight (humidity rises) then suddenly opening up (animals get chilled). Winter ventilation should remove moisture from respiration, manure, and spilled water, while curtain/ridge settings and wind protection keep air entering high, mixing, and settling gently. In many climates, the Cattle Barn goal is controlled ventilation with humidity in a healthy range and minimal condensation, not “shirt-sleeve temperatures” inside the building. Iowa State University Extension: Preparing for Winter & Minimum Ventilation

Special zones: calves, hospital pens, and “draft-sensitive” animals

A Cattle Barn often contains animals with very different needs, and that’s where ventilation mistakes show up fast. Calves and sick animals can be sensitive to drafts, but they still need fresh air—stale, humid air increases respiratory risk. Many farms succeed with natural ventilation plus supplemental systems (like positive pressure tubes) that deliver measured fresh air without a cold jet at calf level. In a Cattle Barn, protect these zones by controlling inlet location, avoiding airflow “shortcuts” from older animals toward youngstock, and keeping bedding and floors dry so the microclimate doesn’t become a pathogen incubator. The Dairyland Initiative (UW–Madison): Calf Barn Ventilation

Manure handling starts with barn geometry: slopes, alleys, and traffic

If manure is hard to move, the Cattle Barn will never stay clean—no matter how motivated the crew is. Design choices like alley width, crossovers, floor texture, and slope influence scraper performance, skid-steer maneuvering, and whether flush water travels where it should. Bedding type also matters: sand can improve cow comfort but changes the entire manure-handling strategy, from separation to wear on pumps and pipes. A good Cattle Barn layout creates a logical manure “path” from where it’s dropped to where it’s collected, with minimal bottlenecks and easy access for maintenance so the system stays reliable year-round. MU Extension: Dairy Manure Management Systems (solid, slurry, lagoon basics)

Choose a collection system that matches bedding, water use, and labor reality

In a Cattle Barn, the “best” manure system is the one that matches your bedding choice, climate, and labor. Scrape systems can be simple and water-efficient, but they require good traction, durable scrapers, and a plan for where scraped manure goes next. Flush systems can move manure quickly in large barns, but they demand water management, separation, and carefully designed channels and slopes. Hybrid approaches are common in a Cattle Barn with mixed areas (maternity, sick pens, holding areas), where you may need different tools for different zones. Design for maintenance access—because every manure system eventually needs service at the worst possible time. The Dairyland Initiative (UW–Madison): Manure Management (design details & flow considerations)

Manure storage: engineer it like a structure, not an afterthought

A compliant Cattle Barn manure plan includes storage capacity that fits your land base, weather delays, and hauling windows—so you’re not forced into bad timing. Storage structures also need sound siting (including flood considerations), geotechnical evaluation, and design that protects surface and groundwater. Whether you use tanks, pits, or lagoons, treat storage as engineered infrastructure with defined capacity, safety features, and inspection points. A Cattle Barn that “works on paper” but ignores site conditions (soils, water table, drainage) often becomes an expensive rework. Build the storage plan to meet local rules and proven engineering standards, and document the rationale for permitting and insurer confidence. USDA NRCS: Conservation Practice Standard 313 (Waste Storage Facility)

Nutrient management and CAFO expectations: design for documentation

Even if your farm isn’t a permitted CAFO, the Cattle Barn manure system should make recordkeeping and nutrient accountability easier, not harder. That means planning sampling points, tracking storage volumes, and designing land-application logistics that support “right rate, right time, right place.” For permitted operations, nutrient management plans typically include minimum measures related to manure/wastewater handling, land application protocols, and monitoring—so your Cattle Barn infrastructure should support those requirements (access points, containment, separation of clean water, and predictable storage/hauling). When you design the barn and storage together, you reduce spill risk and make compliance a routine process instead of a scramble. US EPA: Understanding Nutrient Management Plans (NMP minimum measures)

Manure gas and confined-space safety: design out the hazards

A safe Cattle Barn treats manure storages—especially pits and enclosed structures—as high-risk areas during agitation and pumping. Toxic and flammable gases can be released quickly, and oxygen can be displaced in ways that overwhelm people and animals before there’s time to react. Design features that help include guarded openings, secure covers, safe access from outside the space, ventilation capability, and clear lockout/tagout procedures for moving equipment. Operationally, a Cattle Barn needs posted rules: keep unauthorized people out, never work alone, remove animals during agitation when appropriate, and treat entry as a confined-space event with monitoring and planning. OSHA: Working Safely Around Manure Storage Structures

Why hydrogen sulfide deserves extra attention

In a Cattle Barn manure context, hydrogen sulfide is especially dangerous because it can be toxic at low concentrations, can accumulate in low-lying or poorly ventilated areas, and can overcome people rapidly—sometimes including would-be rescuers. That’s why the safest strategy is prevention: avoid entry, ventilate aggressively when needed, monitor the atmosphere, and design systems so serviceable parts are accessible from outside dangerous spaces. A Cattle Barn that relies on “someone holding their breath for a quick fix” is eventually going to have a crisis. Treat manure storages like industrial hazards, not routine work zones, and train everyone (including family and part-time help) on what not to do. CDC/NIOSH: Manure Pits Continue to Claim Lives

Electrical and ignition control in corrosive barn environments

Electrical systems in a Cattle Barn take a beating from dust, moisture, and corrosive gases, so the design must prioritize durability and protection. Use agricultural/commercial-rated equipment, protect fixtures from dust and impact, keep wiring properly installed and enclosed, and avoid “temporary” fixes that become permanent. Heat lamps, space heaters, and overloaded cords are common ignition pathways in barns, so the Cattle Barn plan should include dedicated circuits where needed and clear rules about what devices are allowed. Also plan for routine cleaning around electrical areas—dust and cobweb buildup can turn a minor fault into a fast-moving fire. SDSU Extension: Electrical Safety in the Barn

Fire prevention habits that should be built into the barn plan

Many barn fires trace back to preventable basics: poor housekeeping around electrical points, unsafe heaters/lamps, smoking, hot work without controls, and storing combustibles too close to ignition sources. A practical Cattle Barn design sets you up for safer habits by creating defined storage zones (hay, bedding, fuels) away from the main animal area, maintaining clear exit paths, and making it easy to keep dust under control. Add the right tools: ABC extinguishers near exits and high-risk zones, clearly marked shutoffs, and a simple emergency plan posted where everyone can see it. Then reinforce it with inspections—because the most dangerous barn is the one people assume is “fine.” Ohio State University: Preventing Barn Fires

Fire codes and emergency planning: treat “ag buildings” as regulated buildings

Fire code expectations for a Cattle Barn depend on use, occupancy, size, and local adoption of building/fire codes, so the smartest move is to involve your local building department and fire marshal early. Even where agricultural buildings have special classifications, codes commonly still influence access, exits, electrical requirements, separation distances, and what safety equipment may be required. A Cattle Barn emergency plan should include posted addresses/GPS, water sources, equipment shutoffs, and a livestock evacuation concept that doesn’t put humans at unreasonable risk. Design choices—door hardware, outward-opening/sliding doors, clear aisles, and access routes—can save critical minutes. ICC Digital Codes: IBC Appendix C (Group U Agricultural Buildings)

Final thought

The best Cattle Barn designs feel “boringly predictable” in daily life: fresh air without drama, manure moving where it should, and fire risks controlled by both design and routine. If you’re building new or retrofitting, think in systems—ventilation + layout + manure + electrical + emergency access—because fixing one piece while ignoring the others usually creates a new bottleneck. In the U.S., involving a qualified builder/engineer and your local authority early can prevent expensive rework and keep insurance and permitting straightforward, while a written inspection routine keeps the Cattle Barn safe long after the ribbon-cutting day. NFPA Barn Fire Safety Checklist (PDF)

Sources & References

- Purdue Extension: Natural Ventilation for Livestock Housing (AE-97)

- UW–Madison Extension: Natural Ventilation in Dairy Buildings

- UW–Madison Extension: Ventilation in Dairy Buildings

- University of Minnesota Extension: Heat Stress in Dairy Cattle

- Iowa State University Extension: Preparing for Winter & Minimum Ventilation

- The Dairyland Initiative: Calf Barn Ventilation

- MU Extension: Dairy Manure Management Systems

- The Dairyland Initiative: Manure Management

- USDA NRCS: Conservation Practice Standard 313 (Waste Storage Facility)

- US EPA: Understanding Nutrient Management Plans

- OSHA: Working Safely Around Manure Storage Structures (PDF)

- CDC/NIOSH: Manure Pits Continue to Claim Lives

- SDSU Extension: Electrical Safety in the Barn

- Ohio State University: Preventing Barn Fires

- NFPA Barn Fire Safety Checklist (PDF)

- University of Kentucky: Preventing Barn Fire (ASC-184 PDF)

- ICC Digital Codes: IBC Appendix C (Group U)