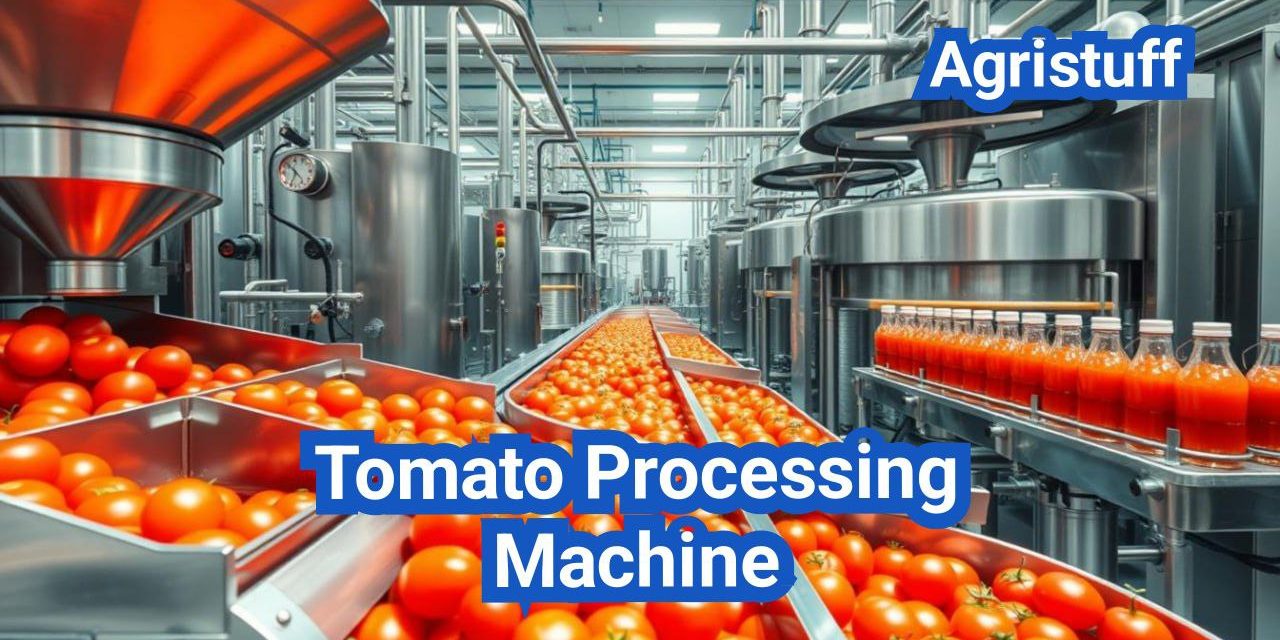

The production of tomato products, such as paste, sauce, and juice, relies heavily on advanced tomato processing machines. These machines are crucial in the food industry, enabling efficient and sanitary production processes.

From receiving and washing to sorting and filling, a comprehensive production line ensures high-quality output. EasyReal Tech provides complete production lines, including aseptic filling machines and tomato paste evaporators, designed to meet the demands of large-scale production while maintaining product integrity.

Key Takeaways

- Efficient production of tomato products relies on advanced machinery.

- A comprehensive production line includes receiving, washing, sorting, and filling processes.

- Aseptic filling machines ensure sanitary packaging.

- Tomato paste evaporators play a crucial role in producing high-quality paste.

- Complete production lines are designed for large-scale production.

The Evolution of Tomato Processing Technology

The evolution of tomato processing technology has been marked by significant innovations, improving efficiency and product quality. Over the years, the industry has witnessed a transformation from traditional manual methods to sophisticated automated systems.

Historical Development of Processing Methods

Historically, tomato processing involved labor-intensive methods, including manual sorting, crushing, and cooking. The early 20th century saw the introduction of mechanized processing equipment, which significantly increased production capacity. The development of pulping and refining machines further enhanced the efficiency of tomato processing.

The collaboration between companies like Tukas, a Turkish entity, and CFT for tomato paste processing lines exemplifies the advancements in the industry. Such partnerships have led to the development of more efficient and cost-effective processing technologies.

Modern Advancements in Automation

Modern tomato processing technology has been revolutionized by automation. Automated sorting systems, advanced pulping machines, and aseptic filling technologies have become integral to the industry. These advancements have not only improved product quality but also reduced labor costs and increased production efficiency.

Automation in tomato processing has also led to better consistency and reduced variability in the final product. Advanced sensors and control systems enable real-time monitoring and adjustments, ensuring optimal processing conditions.

| Technology | Description | Benefits |

|---|---|---|

| Automated Sorting | Uses optical sensors to sort tomatoes based on quality and size | Improved product quality, reduced labor costs |

| Advanced Pulping Machines | Enhances the efficiency of tomato pulp extraction | Increased production capacity, better product consistency |

| Aseptic Filling Technologies | Ensures sterile packaging, extending product shelf life | Improved food safety, reduced packaging costs |

The role of manufacturers in the USA has been pivotal in advancing tomato processing technology. Companies specializing in processing equipment have driven innovation, providing solutions that cater to the evolving needs of the industry.

Understanding Tomato Processing Machines and Their Functions

Understanding the mechanics and capabilities of tomato processing machines is essential for optimizing production lines. These machines are designed to handle various stages of tomato processing, from initial sorting to final packaging.

Core Components of Processing Systems

Tomato processing machines consist of several core components that work together to ensure efficient production. These include sorting and washing equipment, pulping and refining machines, and evaporation systems for concentrate production.

Key components of these systems often involve:

- Sorting and washing equipment to clean and grade tomatoes

- Pulping machines to break down tomatoes into pulp

- Refining equipment to remove seeds and skin

- Evaporation systems to concentrate the tomato product

Machine Capacity and Throughput Considerations

When selecting tomato processing machines, it’s crucial to consider the machine’s capacity and throughput. This involves understanding the production volume required and matching it with the appropriate equipment.

| Machine Type | Capacity Range | Throughput |

|---|---|---|

| Pulping Machine | 10-50 tons/hour | High |

| Evaporation System | 5-20 tons/hour | Medium-High |

| Aseptic Filling Machine | 100-1000 containers/hour | Variable |

Continuous vs. Batch Processing Equipment

The choice between continuous and batch processing equipment depends on the production requirements and the type of product being manufactured. Continuous processing is often used for high-volume production, offering consistent quality and efficiency.

“Continuous processing allows for a streamlined production process, reducing downtime and increasing overall efficiency.” – Expert in Food Processing Technology

Batch processing, on the other hand, offers flexibility and is often used for specialty or small-batch products.

In conclusion, understanding the functions and capabilities of tomato processing machines is vital for optimizing production. By considering factors such as machine capacity, throughput, and processing type, manufacturers can select the most appropriate equipment for their needs.

Initial Processing: Sorting and Preparation

The journey to high-quality tomato products starts with meticulous sorting and preparation. This initial stage is crucial in determining the final product’s quality and safety.

Optical Sorting Technologies for Tomatoes

Optical sorting technologies have revolutionized the tomato processing industry. These advanced systems use cameras and sensors to inspect tomatoes as they pass through the sorting line, identifying and ejecting any defective or foreign materials. Optical sorting ensures that only the best quality tomatoes are processed, enhancing the overall quality of the final product.

“The use of optical sorting technology has significantly improved our production efficiency and product quality,” says a leading tomato processor. “It’s a game-changer in the industry.”

Washing and Preparation Equipment

Washing and preparation are critical steps following sorting. Tomatoes are washed to remove dirt, bacteria, and other contaminants. Modern washing equipment uses a combination of water jets and brushes to thoroughly clean the tomatoes. This process not only improves the cleanliness of the tomatoes but also helps in removing any remaining foreign materials.

- High-pressure water jets for effective cleaning

- Soft brushes to prevent damage to the tomatoes

- Integrated water recycling systems to conserve resources

Removal of Foreign Materials

The removal of foreign materials is a vital aspect of the initial processing stage. Foreign materials can include stems, leaves, and other debris. Advanced sorting systems, including optical sorters, are designed to detect and remove these materials. Efficient foreign material removal is essential for producing safe and high-quality tomato products.

EasyReal Tech’s production lines, for instance, include integrated systems for receiving, washing, and sorting, along with advanced water filtering systems. This comprehensive approach ensures that tomatoes are processed under optimal conditions, resulting in superior quality products.

Pulping and Refining Operations

Pulping and refining operations play a vital role in determining the quality of the final tomato product. These processes are crucial for breaking down the tomatoes into a usable form, removing unwanted parts, and achieving the desired consistency.

Tomato Crusher and Pulper Machines

The initial step in pulping involves crushing the tomatoes to release their juice and pulp. Tomato crusher and pulper machines are designed to handle large quantities of tomatoes efficiently. These machines use a combination of crushing and heating to break down the tomatoes, making it easier to separate the pulp from the skins and seeds.

The Hot Break and Cold Break technologies are utilized in this process. Hot Break involves heating the tomatoes immediately after crushing to inactivate enzymes that can cause spoilage, while Cold Break involves minimal heating, preserving more of the natural flavor and color.

Refiner Screens and Separation Technology

After the initial pulping, the mixture is refined to achieve the desired consistency and quality. Refiner screens are used to separate the pulp from the seeds and skins. The screens come in different mesh sizes to accommodate various product specifications.

The refining process involves passing the pulp through these screens, which removes any remaining solids, resulting in a smooth, consistent product. This step is critical for producing high-quality tomato sauces and pastes.

Seed and Skin Removal Systems

Effective removal of seeds and skins is essential for the quality of the final product. Advanced seed and skin removal systems are integrated into the refining process to ensure that the final product is free from unwanted particles.

These systems work in conjunction with the refiner screens to ensure a high level of purity and consistency in the final product. The technology used allows for efficient separation, minimizing waste and maximizing yield.

| Machine Type | Function | Key Features |

|---|---|---|

| Tomato Crusher | Crushes tomatoes to release juice and pulp | High capacity, adjustable crushing settings |

| Pulper Machine | Separates pulp from skins and seeds | Efficient separation, minimal waste |

| Refiner Screen | Refines pulp to desired consistency | Adjustable mesh sizes, high precision |

Hot Break vs. Cold Break Processing Methods

The choice between hot break and cold break processing methods significantly impacts the quality and characteristics of tomato products. These two techniques are fundamental in tomato processing, influencing the final product’s flavor, texture, and nutritional content.

Hot Break Processing Technique and Equipment

Hot break processing involves heating tomatoes immediately after crushing to inactivate enzymes that can cause spoilage and affect product quality. This method typically uses heat exchangers or steam injection to raise the temperature to around 180°F (82°C) or higher. The hot break process helps preserve the product’s color and flavor by reducing enzymatic activity.

Key equipment used in hot break processing includes:

- Heat exchangers

- Steam injection systems

- Crushers and pulpers

Cold Break Processing Applications

Cold break processing, on the other hand, involves minimal heating of the tomatoes during the initial crushing stage. This method is preferred for producing products where a fresh, raw flavor is desired. Cold break processing typically occurs at temperatures below 140°F (60°C), preserving the natural enzymes and flavor compounds.

Cold break processing is commonly used for:

- Fresh tomato juice

- Organic tomato products

- Products requiring minimal heat treatment

Impact on Final Product Quality

The choice between hot break and cold break processing significantly affects the final product’s quality. Hot break processing results in a product with better color retention and reduced enzymatic activity, while cold break processing preserves the fresh flavor and natural enzymes.

| Processing Method | Temperature | Product Characteristics |

|---|---|---|

| Hot Break | 180°F (82°C) or higher | Better color retention, reduced enzymatic activity |

| Cold Break | Below 140°F (60°C) | Preserves fresh flavor, natural enzymes |

EasyReal Tech utilizes both hot break and cold break technologies for tomato juice extraction, catering to diverse customer requirements. The selection of processing method depends on the desired product characteristics and end-use applications.

Evaporation Systems for Tomato Paste Production

Advanced evaporation systems are essential for modern tomato paste production, enabling manufacturers to achieve high-quality products while optimizing energy consumption.

Falling-Film Evaporators

Falling-film evaporators are widely used in tomato paste production due to their efficiency and ability to handle viscous products. These evaporators work by distributing the tomato product as a thin film on the inner surface of vertical tubes, where it flows downward under gravity.

The key benefits of falling-film evaporators include:

- High heat transfer rates

- Short residence time, preserving product quality

- Flexibility in handling different product concentrations

MVR/TVR Evaporation Technology

Mechanical Vapor Recompression (MVR) and Thermal Vapor Recompression (TVR) are advanced technologies used to enhance the energy efficiency of evaporation systems. MVR involves compressing the vapor generated during evaporation, while TVR uses a steam ejector to recompress the vapor.

These technologies offer significant advantages, including:

- Reduced energy consumption

- Lower operating costs

- Improved overall efficiency of the evaporation process

Energy Efficiency and Recovery Systems

Energy efficiency is a critical consideration in tomato paste production. Modern evaporation systems incorporate various energy-saving measures, such as:

- Multiple-effect evaporation

- Vapor recompression

- Heat recovery systems

These measures help minimize energy consumption and reduce production costs.

Concentration Control Parameters

Accurate control of concentration is crucial in tomato paste production. Key parameters include:

- Temperature control

- Pressure monitoring

- Solids content measurement

Advanced control systems enable precise regulation of these parameters, ensuring consistent product quality.

Specialized Tomato Processing Machines for Sauce Production

Specialized tomato processing machines play a crucial role in sauce production, enhancing efficiency and quality. The production of tomato sauce involves a series of complex processes, from pulping to refining, and finally to packaging. Advanced machinery is designed to handle these tasks with precision, ensuring that the final product meets the required standards.

Sauce Finishing Equipment

Sauce finishing equipment is critical in the final stages of sauce production. These machines are designed to refine the sauce, removing any remaining impurities and achieving the desired consistency. Finishing machines often incorporate advanced technologies such as centrifugal separation and micro-filtration to produce a smooth, high-quality sauce.

Ingredient Mixing Systems

Ingredient mixing systems are another vital component in the production of tomato sauce. These systems ensure that various ingredients, such as spices, herbs, and preservatives, are evenly distributed throughout the sauce. Advanced mixing technologies allow for precise control over the mixing process, ensuring consistency and quality in the final product.

EasyReal Tech’s machines, for instance, can produce tomato ketchup and sauce directly from fresh tomatoes, showcasing the integration of mixing and processing technologies.

Consistency Control Technology

Consistency control technology is essential for achieving the desired texture and viscosity in tomato sauce. These systems utilize various methods, including temperature control and viscosity measurement, to ensure that the sauce meets the required specifications. Consistency control is critical for maintaining product quality and consumer satisfaction.

In conclusion, specialized tomato processing machines are indispensable in the production of high-quality tomato sauce. From sauce finishing equipment to ingredient mixing systems and consistency control technology, these machines work together to ensure efficient and effective production processes.

Heat Treatment and Pasteurization Systems

The application of heat treatment and pasteurization systems in tomato processing is essential for eliminating harmful bacteria and extending shelf life. These processes are critical in ensuring the safety and quality of tomato products, from paste to sauce.

Tubular Heat Exchanger UHT Systems

Tubular heat exchanger UHT (Ultra-High Temperature) systems are widely used in the tomato processing industry for their efficiency and effectiveness in heat treatment. These systems involve heating the product to a very high temperature for a short period, followed by rapid cooling. This process ensures the destruction of microorganisms while preserving the nutritional and sensory qualities of the product.

Key benefits of tubular heat exchanger UHT systems include:

- High efficiency in heat transfer

- Ability to handle viscous products

- Compact design for easier integration into processing lines

Temperature Control and Food Safety

Temperature control is a crucial aspect of heat treatment and pasteurization. Maintaining the correct temperature ensures that the product is heated sufficiently to kill harmful bacteria without compromising its quality. Advanced temperature control systems are equipped with precise monitoring and adjustment capabilities to guarantee consistent results.

Effective temperature control measures include:

- Real-time temperature monitoring

- Automated adjustment of heating parameters

- Regular maintenance of heating equipment

Cooling Systems and Temperature Management

After heat treatment, cooling systems play a vital role in rapidly reducing the product temperature to prevent further bacterial growth and preserve product quality. Efficient cooling systems are designed to work in tandem with heat treatment processes, ensuring a seamless transition from heating to cooling.

The table below summarizes the key components and considerations for heat treatment and pasteurization systems in tomato processing:

| System Component | Function | Considerations |

|---|---|---|

| Tubular Heat Exchanger | Heats product to UHT | Efficiency, viscosity handling |

| Temperature Control System | Monitors and adjusts temperature | Precision, automation |

| Cooling System | Rapidly cools product | Efficiency, capacity |

Quality Control in Tomato Processing

Effective quality control is crucial in tomato processing to ensure the production of high-quality products. Tomato processing facilities rely on various measures to maintain consistency and integrity in their products.

Measuring Bostwick Consistency

The Bostwick consistometer is a widely used tool for assessing the consistency of tomato products, such as sauces and pastes. It measures the flow distance of a sample under gravity, providing a quantitative assessment of product viscosity.

Monitoring Tomato Solids (°Brix)

Tomato solids content, measured in °Brix, is a critical parameter in tomato processing. It indicates the concentration of soluble solids, primarily sugars, in the product. Accurate °Brix measurement is essential for ensuring product quality and consistency.

Meeting Standards of Identity for Tomato Products

Tomato products must comply with specific standards of identity, which define the characteristics and composition of various tomato-based products. These standards help ensure that products are labeled accurately and meet consumer expectations.

In-line Testing Equipment

In-line testing equipment plays a vital role in maintaining product quality during tomato processing. These systems enable real-time monitoring of product characteristics, allowing for immediate adjustments to be made as needed.

By implementing these quality control measures, tomato processing facilities can ensure the production of high-quality products that meet industry standards and consumer expectations. EasyReal Tech’s machines are designed with these quality control considerations in mind, producing products that are consistent and of high quality.

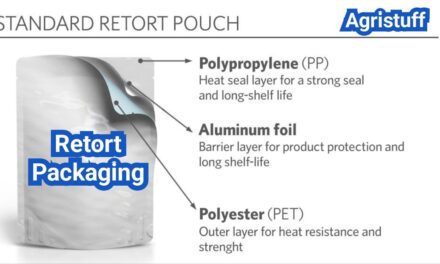

Aseptic Filling Technology

Aseptic filling is a critical step in the production of tomato products, ensuring their safety and quality. This process involves filling and packaging products in a sterile environment to prevent contamination.

Bag-in-Drum Aseptic Systems

Bag-in-drum aseptic systems are a popular choice for packaging tomato products. These systems offer a sterile and efficient way to store and transport products. The bag-in-drum design allows for flexible storage options and minimizes the risk of contamination.

According to a report by a leading industry expert, “Bag-in-drum aseptic systems have revolutionized the way we package and store food products, providing a safe and reliable solution for manufacturers.”

“The use of bag-in-drum aseptic systems has become increasingly popular in the food processing industry due to their ability to maintain product sterility and reduce packaging waste.”

— Food Processing Magazine

Sterile Filling Processes

Sterile filling processes are crucial in maintaining the quality and safety of tomato products. This involves using specialized equipment and techniques to fill containers in a sterile environment.

| Process | Description | Benefits |

|---|---|---|

| Sterile Filling | Filling containers in a sterile environment | Prevents contamination, ensures product safety |

| Aseptic Packaging | Packaging products in a sterile environment | Maintains product sterility, extends shelf life |

Packaging Options and Considerations

When it comes to packaging tomato products, there are several options to consider. The choice of packaging depends on factors such as product type, storage requirements, and distribution channels.

- Bag-in-drum

- Aseptic cartons

- Sterile pouches

Maintaining Sterility Throughout Filling

Maintaining sterility throughout the filling process is critical to ensuring the quality and safety of tomato products. This involves using specialized equipment and implementing strict sanitation protocols.

Key considerations for maintaining sterility include:

- Regular cleaning and sanitization of equipment

- Use of sterile packaging materials

- Training personnel on proper handling and filling techniques

Leading Tomato Processing Machine Manufacturers in the USA

Tomato processing machine manufacturers in the USA are known for their innovative solutions, catering to the diverse needs of the food processing industry. These manufacturers have been at the forefront of developing advanced machinery that enhances efficiency, quality, and safety in tomato processing.

Top American Manufacturers

The US is home to several top American manufacturers who specialize in producing high-quality tomato processing equipment. Companies like EasyReal Tech have made significant contributions to the global market, offering a range of machinery from pulping to aseptic filling systems.

These manufacturers have a strong reputation for delivering reliable, efficient, and sanitary equipment that meets the stringent requirements of the food industry. Their products are designed to optimize production processes, reduce waste, and improve the overall quality of tomato products.

Specialized Equipment Providers

In addition to general processing equipment, there are specialized equipment providers who focus on specific aspects of tomato processing. These include manufacturers of optical sorting technologies, sauce finishing equipment, and evaporation systems for tomato paste production.

Such specialization allows for a more tailored approach to the diverse needs of tomato processors, enabling them to select equipment that precisely meets their production requirements.

Service and Support Considerations

When selecting a tomato processing machine manufacturer, it’s crucial to consider the level of service and support they offer. This includes installation, maintenance, training, and after-sales support.

Leading manufacturers understand the importance of providing comprehensive support to ensure their equipment operates at peak performance throughout its lifespan. This not only enhances customer satisfaction but also contributes to the long-term success of the processing operation.

By choosing a reputable and supportive manufacturer, tomato processors can benefit from optimized production processes, reduced downtime, and improved product quality.

Cost Analysis of Tomato Processing Equipment

Understanding the total cost of ownership is essential for tomato processing equipment. This involves more than just the initial purchase price; it encompasses a range of costs including operational expenses, maintenance, and potential return on investment.

Initial Investment Considerations

The initial investment in tomato processing equipment can be substantial. Manufacturers must consider the cost of the machines themselves, as well as any additional features or accessories required for operation. EasyReal Tech’s machines are designed to be energy-efficient, reducing production costs.

When evaluating initial investment costs, consider the following factors:

- Machine capacity and throughput

- Technology and automation level

- Material and construction quality

- Compliance with regulatory standards

Operational and Maintenance Costs

Operational costs include energy consumption, labor, and raw materials. Maintenance costs involve regular servicing, replacement parts, and potential downtime. Efficient maintenance scheduling can significantly reduce overall costs.

| Cost Component | Description | Impact on Total Cost |

|---|---|---|

| Energy Consumption | Cost of electricity or fuel used during operation | High |

| Labor Costs | Cost of personnel operating and maintaining equipment | Medium |

| Maintenance | Cost of parts and service for equipment upkeep | Medium |

Return on Investment Calculations

Calculating the return on investment (ROI) for tomato processing equipment involves comparing the cost savings or revenue generated by the equipment against its total cost. A positive ROI indicates that the investment is profitable.

“The ROI calculation should consider both direct and indirect benefits, such as increased efficiency and reduced waste.”

Financing Options for Processing Equipment

Various financing options are available for tomato processing equipment, including loans, leasing, and equipment financing programs. Manufacturers should explore these options to find the most suitable arrangement for their business needs.

By carefully analyzing the total cost of ownership and exploring financing options, manufacturers can make informed decisions about investing in tomato processing equipment.

Small-Scale vs. Industrial Tomato Processing Machines

Tomato processing machines vary significantly in size and capacity, catering to both small producers and industrial manufacturers. The choice between small-scale and industrial machines depends on several factors, including production volume, available resources, and specific product requirements.

Options for Small Producers

Small-scale tomato processing machines are ideal for producers with limited production volumes or those who are just starting out in the industry. These machines are typically more affordable and require less space, making them suitable for small farms or local processors. EasyReal Tech offers production lines with daily capacities as low as 20 tons, providing an entry-point for small producers into the market.

Large-Scale Industrial Solutions

On the other end of the spectrum, industrial tomato processing machines are designed for high-volume production. These machines are capable of handling large quantities of tomatoes and are often used by major manufacturers in the industry. Industrial-scale equipment can significantly increase efficiency and reduce costs per unit, making it a viable option for large producers looking to maximize their output.

Scalability and Expansion Considerations

One of the key considerations when choosing between small-scale and industrial tomato processing machines is scalability. As production needs grow, manufacturers may need to expand their operations. Scalable processing solutions allow for easier upgrades and expansions, minimizing downtime and reducing the need for significant overhauls.

Popular Models for Different Production Scales

Different production scales require different models of tomato processing machines. For small producers, compact and versatile machines are preferred, while large industrial operations often utilize complex, high-capacity systems. EasyReal Tech’s range of production lines, with capacities from 20 tons to 1500 tons per day, cater to a wide range of production scales, providing flexibility and options for manufacturers at various stages of their operations.

Regulatory Compliance and Food Safety

Regulatory compliance is crucial for maintaining food safety in tomato processing. The industry is subject to various regulations and standards to ensure the production of safe and high-quality products.

FSMA Preventive Controls

The Food Safety Modernization Act (FSMA) emphasizes preventive controls to minimize the risk of contamination in food processing facilities. Tomato processing plants must implement robust preventive controls, including:

- Identifying potential hazards in the production process

- Implementing controls to mitigate these hazards

- Monitoring and verifying the effectiveness of these controls

EasyReal Tech’s machines, for instance, are designed with high-quality SUS304 and SUS316L stainless steel, ensuring durability and corrosion resistance, which is critical for maintaining a clean and safe processing environment.

3-A Sanitary Design Standards

The 3-A Sanitary Standards organization provides guidelines for designing equipment that can be easily cleaned and sanitized. Compliance with these standards is essential for ensuring food safety in tomato processing. Key aspects include:

| Design Feature | Description | Benefit |

|---|---|---|

| Self-draining surfaces | Surfaces are designed to prevent liquid accumulation | Reduces risk of bacterial growth |

| Easy-to-clean components | Components are designed for simple disassembly and cleaning | Enhances cleaning efficiency |

| Sanitary fittings and valves | Fittings and valves are designed to prevent contamination | Maintains product purity |

Cleaning and Sanitization Protocols

Effective cleaning and sanitization are critical for preventing contamination in tomato processing facilities. Protocols should include:

- Pre-cleaning to remove gross contamination

- Cleaning with appropriate detergents

- Sanitization to reduce microbial load

- Verification of cleaning and sanitization effectiveness

“Cleaning and sanitizing are not just about compliance; they’re about ensuring the safety and quality of our products.”

— Food Safety Expert

Documentation and Traceability Requirements

Maintaining detailed records of processing, cleaning, and sanitization activities is essential for demonstrating compliance with regulatory requirements. Traceability systems enable the tracking of products through the supply chain, facilitating recalls if necessary.

Key documentation includes:

- Cleaning and sanitization schedules

- Production records

- Supplier verification documents

By adhering to these regulatory compliance and food safety measures, tomato processors can ensure the production of safe, high-quality products while maintaining compliance with relevant regulations.

Optimizing Your Tomato Processing Operation

Optimizing tomato processing operations requires a comprehensive approach that encompasses the right equipment, efficient processes, and regulatory compliance. By understanding the evolution of tomato processing technology and the functions of various machines, processors can make informed decisions to enhance their operations.

Selecting the appropriate tomato processing equipment is crucial, from pulping and refining to aseptic filling. EasyReal Tech’s advanced technology and comprehensive solutions can help streamline these processes, improving overall efficiency and product quality.

Ensuring regulatory compliance is also vital in tomato processing operations. By adhering to standards such as FSMA Preventive Controls and 3-A Sanitary Design, processors can maintain high levels of food safety and quality.

By implementing these strategies and leveraging cutting-edge technology, tomato processors can optimize their operations, reduce costs, and improve their bottom line. Effective optimization of tomato processing operations ultimately leads to increased productivity and competitiveness in the market.

FAQ

What is the primary function of a tomato processing machine?

The primary function of a tomato processing machine is to process tomatoes into various products such as tomato paste, sauce, and juice, from pulping to aseptic filling.

How have tomato processing methods evolved over time?

Tomato processing methods have evolved significantly, from traditional manual methods to modern automated systems, improving efficiency and product quality.

What are the key components of a tomato processing system?

The key components include sorting and washing equipment, pulping and refining machines, evaporation systems, and aseptic filling technology.

What is the difference between hot break and cold break processing methods?

Hot break processing involves heating tomatoes immediately after crushing to inactivate enzymes, while cold break processing involves minimal heating, preserving more natural flavor and color.

What type of evaporator is commonly used in tomato paste production?

Falling-film evaporators are commonly used in tomato paste production due to their efficiency and ability to handle high-viscosity products.

How is quality control maintained in tomato processing?

Quality control is maintained through measures such as measuring Bostwick consistency, monitoring tomato solids (°Brix), and meeting standards of identity for tomato products.

What is aseptic filling technology, and why is it important?

Aseptic filling technology involves filling sterilized products into sterile containers, maintaining sterility throughout the process to ensure product safety and quality.

What are the considerations for choosing between small-scale and industrial tomato processing machines?

Considerations include production scale, budget, and scalability, with small-scale machines suitable for small producers and industrial machines for large-scale production.

What regulatory compliance measures are essential in tomato processing?

Essential measures include FSMA preventive controls, 3-A sanitary design standards, cleaning and sanitization protocols, and documentation and traceability requirements.

How can tomato processing operations be optimized?

Operations can be optimized by selecting the right equipment, implementing efficient processes, and ensuring regulatory compliance to achieve operational excellence.

What are the benefits of using automated tomato sorting machines?

Automated tomato sorting machines improve efficiency, reduce labor costs, and enhance product quality by accurately sorting tomatoes based on size, color, and quality.

What is the role of tubular heat exchangers in tomato processing?

Tubular heat exchangers are used for UHT processing, providing efficient heat transfer and ensuring food safety by sterilizing products.

How do manufacturers of tomato processing machines support their customers?

Manufacturers provide service and support, including maintenance, troubleshooting, and training, to ensure customers can operate their equipment effectively.

Conclusion of: Tomato Processing Machine

What a tomato processing machine really is (and why it matters)

A modern tomato processing machine is best understood as a full, integrated line—washers, sorters, crushers, refiners, evaporators, sterilizers, and aseptic fillers—that transforms raw tomatoes into stable, spec-driven purée, paste, diced products, and sauces. U.S. processors rely on a tomato processing machine to deliver consistent quality, predictable yields, and compliance with food-safety and labeling rules while reducing operating costs and waste. Tetra Pak: Tomato processing overview

Standards of identity that shape the line

Your tomato processing machine must consistently hit U.S. standards of identity that distinguish purée/pulp from paste by natural tomato soluble solids (°Brix). “Tomato purée” is ≥8% but <24% NTSS; “tomato paste” is ≥24%. These thresholds drive evaporation setpoints, in-line QC, and labeling claims. Designing the tomato processing machine around these numbers prevents rework and market confusion. 21 CFR §155.191 (eCFR)

Acid vs. acidified vs. low-acid: classify early, design accordingly

Although tomatoes are generally acidic, a tomato processing machine must account for product pH: acid foods (pH ≤4.6–4.7 depending on product), acidified foods (low-acid adjusted to ≤4.6), and low-acid canned foods (>4.6). The classification determines your process filings, lethality targets, packaging, and verification data. Engaging a process authority ensures the tomato processing machine operates with validated schedules. FDA: Acidified & Low-Acid Foods

FSMA & cGMP: the operational backbone

Every tomato processing machine runs under a Food Safety Plan that meets FSMA Preventive Controls (21 CFR Part 117): hazard analysis, preventive controls, monitoring, verification, corrective actions, and diligent records. On top, cGMPs cover personnel, sanitation, allergen controls, and supplier programs. A strong plan lets the tomato processing machine achieve safe, repeatable outcomes at scale. FDA: FSMA Preventive Controls

Receiving, washing, and primary sorting

Upstream of the tomato processing machine, wet flumes and spray washers remove field soil and debris, while de-stoners and magnets protect downstream equipment. Optical sorters reject foreign materials, decay, and color defects to stabilize yield and safety before pulping. Tight incoming QA reduces stoppages throughout the tomato processing machine. TOMRA Sentinel II

Secondary sorting to lock in consistency

Because raw tomatoes vary by lot and varietal, your tomato processing machine benefits from a second optical pass tuned to size, color, and defect classes. Modern systems store “recipes” for different products, maintaining repeatable outcomes without frequent manual tweaks—key for a stable tomato processing machine. Key Technology VERYX® 2.0

Crushing & pulping: building a clean base

After washing, the tomato processing machine crushes fruit into slurry and separates skins and seeds using pulpers/refiners (and sometimes super-refiners). Proper preheating reduces enzyme activity and microbial load, while sieving trains deliver the particle profile your customer expects—setting the tomato processing machine up for efficient concentration. FAO: Tomato processing steps

Hot-break vs. cold-break: texture, color, and flavor

A key choice in any tomato processing machine is enzyme inactivation. Hot-break (~95–100 °C) preserves pectin for higher viscosity (preferred for ketchup/paste), while cold-break (~65–75 °C) retains fresher flavor but gives lower viscosity. Understanding this trade-off lets the tomato processing machine meet product-specific specs. Peer-reviewed summary (PMC)

Typical hot-break parameters in practice

In many plants, the tomato processing machine applies rapid hot-break immediately after crushing to inactivate pectinases, then refines and concentrates under vacuum. Time/temperature are tuned to viscosity targets and color retention to protect quality throughout the tomato processing machine. FAO: Tomato concentrate process notes (PDF)

Refining & finishers: particle control for final specs

Screen selection in the tomato processing machine balances mouthfeel and yield while removing seed/peel fragments. Tight control of differential pressures prevents seed breakage (bitterness) and ensures a clean, stable base for paste or purée, reducing defects later in the tomato processing machine. FAO: Sieving & refining

Concentration: falling-film vs. forced-circulation

Evaporation is the energy hub of a tomato processing machine. Falling-film evaporators provide gentle, short residence-time concentration under vacuum; forced-circulation units handle viscous hot-break pastes without fouling. Matching the evaporator to the product rheology is central to an efficient tomato processing machine. GEA: Falling-film evaporators

Energy strategy: multi-effect, TVR, and MVR

To cut steam and electricity, a tomato processing machine can use multi-effect evaporation with thermo-vapor recompression (TVR) or mechanical vapor recompression (MVR). These options recover latent heat and reduce overall OPEX—vital when the tomato processing machine runs continuously during harvest peaks. SPX FLOW: Evaporators & recompression

Sterilization: tubular UHT for viscous products

Before sterile filling, the tomato processing machine sterilizes paste or purée using tubular heat exchangers sized for fibers and high viscosity, achieving commercial sterility with minimal burn-on and color loss. Clean-in-place design minimizes downtime in the tomato processing machine. Alfa Laval Steritherm VLA

Direct-steam injection with flash cooling

Some tomato processing machine setups use direct-steam injection followed by vacuum flash to reduce thermal abuse and protect color. The approach enables tight residence-time control and reduces fouling—extending run-length for the tomato processing machine. JBT: Aseptic Flash Cooler

Aseptic filling: drums and bins for ambient storage

At the end of the tomato processing machine, product is aseptically filled into 55-gal drums or ~300-gal bins. Properly sterilized bags, steam-sterilized fitments, and validated filling heads preserve sterility, enabling long ambient storage and efficient global logistics from the tomato processing machine. JBT: ABF1200 Aseptic Bag Filler

Bag-in-box/bag-in-drum packaging considerations

Choosing bags with the right oxygen barrier, fitments, and secondary packaging helps a tomato processing machine minimize waste and contamination. Closed-loop dispensing protects product through the user’s process, preserving the quality created by the tomato processing machine. SIG: Bag-in-Box solutions

Industrial pack formats & specs

Many U.S. suppliers running a tomato processing machine offer aseptic paste in 55-gal drums (~540 lb net) and 300-gal bins, declaring NTSS (°Brix), color, and viscosity. Publishing tight spec sheets builds buyer confidence and showcases the tomato processing machine’s control. Morning Star: Aseptic tomato paste

Quality control: °Brix measurement

Because solids define labeling and functionality, a tomato processing machine program measures NTSS (°Brix) using refractometric methods recognized by USDA/AMS. Calibration routines ensure repeatability, supporting release decisions from the tomato processing machine. USDA/AMS: Solids determination (PDF)

pH monitoring: a tenth of a point can change everything

Even with naturally acidic tomatoes, a tomato processing machine should monitor pH closely since varietal and seasonal shifts can approach regulatory boundaries; if needed, validated acidification protects safety and shelf stability without over-processing the tomato processing machine’s output. FDA: Acidified & Low-Acid guidance

HACCP & critical control points

Typical CCPs in a tomato processing machine include hot-break inactivation, UHT hold time/temperature, sterile air/steam verification on the filler, and container integrity checks. Documented monitoring and corrective actions prove that the tomato processing machine consistently meets safety targets. FDA: HACCP principles

Sanitary design & CIP: build it clean to keep it clean

Hygienic design lets a tomato processing machine be effectively cleaned and inspected. Following 3-A criteria for welds, slopes, drains, and access points—and validating CIP coverage—reduces downtime and risk across the tomato processing machine. 3-A Sanitary Standards

Aseptic processing expectations from regulators

For acid and acidified tomato products filled aseptically, a tomato processing machine must run with validated schedules, sterility tests, and accurate records. Understanding inspection expectations helps you design documentation that reflects real control at the tomato processing machine. FDA: Aseptic Processing Guide

Heat-exchange blocks matched to product rheology

High-solids and fiber-containing products benefit when a tomato processing machine uses tubular or scraped-surface heat exchangers matched to particle size and pressure drop. Proper selection minimizes shear and burn-on while ensuring uniform heating in the tomato processing machine. Tetra Pak: Tubular heat exchangers

Capacity, run-length, and seasonal strategy

Well-sized buffer tanks, CIP plans, and aseptic storage let a tomato processing machine run long shifts during harvest with minimal stops. Bulk ambient storage in drums/bins bridges crop seasonality, keeping the tomato processing machine’s output available year-round. JBT: Tomato & Fruit Processing System (PDF)

Labeling, grades, and buyer expectations

By engineering your tomato processing machine around defined NTSS, color, and defect limits, you can meet U.S. grade declarations and customer specs. Clear specifications shorten audits and simplify procurement for the tomato processing machine’s buyers. USDA: Tomato paste grades

U.S. buyer checklist for selecting equipment

When shortlisting vendors, ensure the tomato processing machine offers documented hygienic design, robust evaporator options (multi-effect/TVR/MVR), validated UHT curves for your SKUs, full CIP coverage, and compatible aseptic fillers for 55-gal drums and ~300-gal bins. These features future-proof the tomato processing machine. Alfa Laval: Prepared food processing

Putting it all together: data-driven control

From optical sorting and hot-/cold-break to evaporation energy schemes and aseptic filling, a tomato processing machine becomes a stable, high-yield platform when each unit operation is instrumented, trended, and tied to release criteria. This end-to-end visibility turns harvest variability into consistent output from the tomato processing machine. Tetra Pak: Processing equipment portfolio

Final thought

Design your tomato processing machine around the product you intend to sell—choose hot- or cold-break for the target viscosity, size heat-exchange surfaces for gentle sterility, align specs with U.S. standards, and instrument everything from wash to fill. When each step is validated and monitored, the tomato processing machine turns a seasonal crop into reliable, premium ingredients for U.S. brands. FDA: Aseptic processing guide

Sources & References

- 21 CFR §155.191 Tomato concentrates

- FDA: FSMA Preventive Controls

- FDA: Acidified & Low-Acid Foods

- FDA: Aseptic Processing & Packaging

- 3-A Sanitary Standards

- Tetra Pak: Tomato processing

- Tetra Pak: Tubular heat exchangers

- GEA: Falling-film evaporators

- SPX FLOW: Evaporators (TVR/MVR)

- Alfa Laval: Steritherm VLA

- JBT: ABF1200 Aseptic Bag Filler

- JBT: Aseptic Flash Cooler

- SIG: Bag-in-Box

- TOMRA: Sentinel II sorter

- Key Technology: VERYX® 2.0

- FAO: Tomato processing steps

- FAO: Tomato concentrate—process notes (PDF)

- Sridhar et al. (2022): Hot- vs. cold-break effects

- USDA/AMS: Solids content determination (PDF)

- USDA: Tomato paste grades

- Morning Star: Industrial aseptic paste