The journey from raw sugar to white crystals involves a multi-step sugar refining process that transforms coarse, brown sugar into refined white sugar.

Cane sugar is initially partially refined into raw sugar at mills near the sugar fields, whereas beet sugar is processed directly into white sugar at factories. The refining process for both involves several key steps, including purification, filtration, and crystallization.

Understanding the differences between cane and beet sugar processing is crucial, as each has its unique characteristics and requirements. The end result of the refining process is the production of white sugar crystals used in various industries.

Key Takeaways

- The sugar refining process involves multiple steps to produce white sugar from raw sugar.

- Cane and beet sugar undergo different initial processing steps.

- Purification and crystallization are critical in the refining process.

- The final product is used across various industries, from food to pharmaceuticals.

- The refining process enhances the quality and purity of the sugar.

The Evolution of Sugar Refining

The history of sugar refining is a story of continuous improvement and technological advancements. From its early beginnings to the sophisticated processes used today, sugar refining has evolved significantly over time.

Historical Development of Sugar Processing

Sugar refining has its roots in ancient times when sugar was first produced from sugarcane in India. The process was labor-intensive and yielded raw sugar that was far from the white crystals we know today. As trade routes expanded, sugar production spread to other parts of the world, including the Mediterranean region.

The refining process improved over the centuries, with significant advancements during the Industrial Revolution. New technologies and machinery enabled mass production and higher quality sugar. The introduction of beet sugar in the 19th century further expanded the sugar industry, providing an alternative source of sugar.

Modern Advancements in Refining Technology

Today, sugar refining is a highly sophisticated process that utilizes advanced technologies to produce high-quality sugar. Modern refineries employ various techniques, including affination, clarification, decolorization, evaporation, and crystallization, to transform raw sugar into refined white crystals.

Technological advancements have improved efficiency, reduced energy consumption, and enhanced the quality of the final product. For instance, the use of granular activated carbon and ion exchange resins has become common in decolorization processes, while multiple-effect evaporation systems have improved energy efficiency.

| Technology | Description | Impact |

|---|---|---|

| Granular Activated Carbon | Used in decolorization to remove impurities | Improves sugar color and quality |

| Multiple-Effect Evaporation | Energy-efficient method for concentrating sugar syrup | Reduces energy consumption |

| Ion Exchange Resins | Used for further purification and decolorization | Enhances sugar purity and quality |

Sugar Industry in the United States

The sugar industry in the United States is a significant sector, with both cane and beet sugar being produced. The country has a complex system of sugar production and refining, with various companies operating across different regions.

Major sugar refineries are located in areas with access to raw sugar, such as Louisiana and California. These refineries not only produce sugar for domestic consumption but also export sugar to other countries.

The U.S. sugar industry is subject to various regulations and policies, including those related to environmental protection and trade. Companies must comply with these regulations while maintaining competitiveness in the global market.

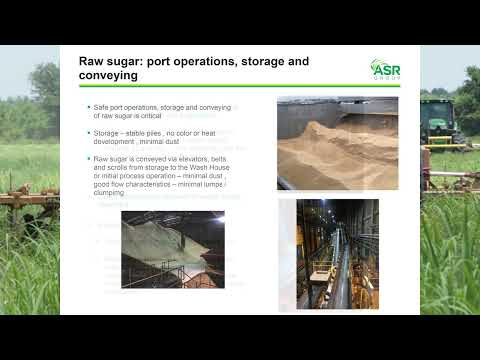

Understanding Raw Sugar: The Starting Material

Understanding the properties of raw sugar is crucial for appreciating the complexities of the sugar refining process. Raw sugar, derived from either sugarcane or sugar beets, is the foundational material that undergoes various transformations to become the white sugar used in households and industries.

Composition and Properties of Raw Sugar | Sugar Refining Process

Raw sugar is characterized by its impurities and moisture content, which vary depending on the source material and the extraction process. Typically, raw cane sugar contains about 96-98% sucrose, with the remaining percentage consisting of impurities such as molasses, water, and non-sugars. The color of raw sugar ranges from dark brown to yellow, influenced by the presence of molasses and other impurities.

The properties of raw sugar, including its moisture content, grain size, and impurity levels, play a significant role in determining the efficiency of the refining process. For instance, raw sugar with higher moisture content may require additional drying steps during refining.

Different Sources: Cane vs. Beet Sugar Processing | Sugar Refining Process

The processing of sugar from cane and beets differs significantly due to the distinct nature of these crops. Cane sugar processing involves extracting juice from sugarcane through crushing or diffusion, followed by clarification and evaporation to produce raw sugar. In contrast, beet sugar processing involves slicing sugar beets into cossettes, from which juice is extracted through diffusion. The juice is then purified and concentrated to produce raw beet sugar.

One of the key differences between cane and beet sugar processing is the presence of raffinose in beet sugar, which can affect the crystallization process. Additionally, beet sugar production typically involves more complex purification steps due to the nature of the impurities present.

Quality Parameters of Raw Sugar | Sugar Refining Process

The quality of raw sugar is evaluated based on several parameters, including polarization (sucrose content), moisture content, color, and impurity levels. The polarization value indicates the sucrose content, with higher values signifying purer raw sugar. Moisture content affects the storage and handling of raw sugar, while color and impurity levels influence the refining process’s complexity and cost.

Raw sugar with lower impurity levels and moisture content is generally considered of higher quality, as it requires less processing to achieve the desired refined sugar quality. The quality parameters of raw sugar are crucial for sugar refineries to determine the appropriate processing strategies and to predict the yield and quality of the final refined sugar product.

The Complete Sugar Refining Process Flow

Understanding the complete sugar refining process flow is crucial for appreciating how raw sugar is converted into refined sugar. The process involves several key steps, from affination to crystallization, and includes various technologies like evaporation and centrifugation.

Sugar Refining Process Flow Diagram | Sugar Refining Process

A sugar refining process flow diagram illustrates the sequence of operations involved in transforming raw sugar into white sugar. This diagram typically includes stages such as affination, clarification, decolorization, evaporation, crystallization, and drying.

The affination stage involves mixing raw sugar with a sugar syrup to remove the molasses coating, improving the purity of the sugar crystals. Clarification follows, where impurities are removed through chemical reactions and filtration.

Sugar Refining Process Flow Chart Analysis | Sugar Refining Process

Analyzing a sugar refining process flow chart reveals the complexity and efficiency of modern sugar refining. Each stage is optimized to maximize sugar recovery and quality. For instance, the decolorization stage uses activated carbon or ion exchange resins to remove color and other impurities.

Evaporation concentrates the sugar liquor, preparing it for crystallization. The crystallization process is carefully controlled to produce sugar crystals of the desired size and quality.

Sugar Mill vs. Sugar Refinery: Understanding the Difference

A sugar mill and a sugar refinery are two distinct facilities with different roles in the sugar production process. A sugar mill is where sugarcane or sugar beets are processed to produce raw sugar. This involves extracting juice from the cane or beets, clarifying it, and then boiling it down to produce raw sugar crystals.

In contrast, a sugar refinery takes the raw sugar produced by the sugar mill and further purifies it to produce white refined sugar. The refining process involves several stages, including affination, clarification, and crystallization, to remove impurities and improve the color and purity of the sugar.

Understanding the difference between these two facilities is essential for grasping the overall sugar production process. While the sugar mill is responsible for the initial production of raw sugar, the sugar refinery is where the final product, white refined sugar, is produced.

Affination: The First Step in Sugar Refining

Affination marks the beginning of the sugar refining journey, where raw sugar undergoes a critical transformation. This initial step is crucial for removing impurities from raw sugar crystals, thereby enhancing the quality of the sugar for further refining.

Principles of the Affination Process | Sugar Refining Process

The affination process involves washing raw sugar crystals with a sugar syrup or water to remove the molasses coating on the crystals. This step is essential because the molasses layer contains many impurities that can affect the color, taste, and overall quality of the final sugar product. The process relies on the principle of diffusion, where the impurities from the molasses layer diffuse into the wash liquid, thus cleaning the sugar crystals.

Affination is a delicate balance between removing impurities and preserving the sugar crystals. The temperature, concentration of the wash liquid, and the duration of the affination process are critical parameters that need to be controlled to achieve optimal results.

Equipment Used in Affination | Sugar Refining Process

The equipment used for affination typically includes centrifuges and affination vessels. Centrifuges are used to separate the washed sugar crystals from the molasses-rich wash liquid. The design of these centrifuges is critical to ensure efficient separation and minimal loss of sugar. Affination vessels are where the raw sugar is mixed with the wash liquid, allowing the impurities to be removed from the sugar crystals.

Modern affination equipment is designed to be more energy-efficient and to minimize waste. The use of advanced materials and designs, such as stainless steel centrifuges, helps in reducing corrosion and improving the overall hygiene of the process.

Importance of Affination in Impurity Removal | Sugar Refining Process

Affination plays a vital role in the sugar refining process by significantly reducing the impurity load on subsequent refining steps. By removing the molasses coating, affination helps in improving the color and purity of the sugar. This step is crucial for producing high-quality refined sugar that meets the required standards for consumption and industrial use.

The efficiency of the affination process directly impacts the overall yield and quality of the refined sugar. Effective affination ensures that the subsequent steps, such as clarification and decolorization, are more effective, leading to a higher quality final product.

Clarification Methods in Sugar Refining

Clarification is a pivotal step in the sugar refining process, ensuring the removal of impurities to produce high-quality sugar. This process is crucial for achieving the desired purity and quality of the final sugar product.

Phosphatation vs. Carbonatation Techniques | Sugar Refining Process

The sugar industry employs two primary clarification techniques: phosphatation and carbonatation. Phosphatation involves the addition of phosphoric acid and lime to form insoluble compounds that trap impurities, which are then removed. Carbonatation, on the other hand, uses carbon dioxide and lime to achieve a similar effect. The choice between these methods depends on the specific requirements of the refinery and the quality of the raw sugar.

| Clarification Method | Chemicals Used | Primary Function |

|---|---|---|

| Phosphatation | Phosphoric Acid, Lime | Traps impurities in insoluble compounds |

| Carbonatation | Carbon Dioxide, Lime | Forms insoluble compounds to remove impurities |

Chemical Reactions During Clarification | Sugar Refining Process

During clarification, chemical reactions play a vital role in removing impurities. In phosphatation, phosphoric acid reacts with lime to form calcium phosphate, which precipitates out, carrying impurities with it. Similarly, in carbonatation, carbon dioxide reacts with lime to form calcium carbonate, which also precipitates, taking impurities along.

The efficiency of these reactions is crucial for the overall quality of the clarified sugar liquor. Factors such as temperature, pH, and the concentration of reactants can significantly influence the outcome of these processes.

Filtration Systems for Clarified Sugar Liquor | Sugar Refining Process

After clarification, the sugar liquor undergoes filtration to remove any remaining impurities. Various filtration systems are employed, including pressure filters and vacuum filters. The choice of filtration system depends on the specific requirements of the refinery, including the volume of sugar liquor to be filtered and the desired level of purity.

Effective filtration is critical for producing high-quality refined sugar. It not only removes impurities but also helps in achieving the desired color and clarity of the final product.

Decolorization Techniques

In the journey from raw sugar to refined white crystals, decolorization techniques play a pivotal role. Decolorization is essential for removing impurities and achieving the desired color and purity of white sugar.

Granular Activated Carbon for Sugar Decolorization

Granular activated carbon (GAC) is a widely used adsorbent in the sugar industry for decolorization. Its high surface area and adsorption capacity make it effective in removing color-causing compounds from sugar syrup. The use of GAC involves passing the sugar liquor through a bed of activated carbon, which adsorbs the impurities, resulting in a clearer and less colored product.

The effectiveness of GAC can be influenced by factors such as the type of carbon used, the contact time between the carbon and the sugar liquor, and the temperature of the process. Regular regeneration of the GAC is necessary to maintain its adsorption capacity.

Ion Exchange Resins in Sugar Processing | Sugar Refining Process

Ion exchange resins are another critical technology used in the decolorization process. These resins can remove ionic impurities from the sugar syrup, contributing to the overall purity and color improvement of the final product. The resins work by exchanging ions in the sugar liquor with ions on the resin, effectively removing impurities.

The selection of appropriate ion exchange resins depends on the specific requirements of the sugar refining process, including the type of sugar being processed and the desired level of purity. Regular maintenance and regeneration of the resins are crucial for their longevity and effectiveness.

Measuring and Achieving White Sugar ICUMSA Color Standards

The International Commission for Uniform Methods of Sugar Analysis (ICUMSA) color standards are widely adopted in the sugar industry to measure the color of sugar. Achieving the required ICUMSA color standards is crucial for producing high-quality white sugar that meets international trade specifications.

The ICUMSA color is measured using a spectrophotometer, which quantifies the color of the sugar solution. The lower the ICUMSA value, the whiter the sugar. Effective decolorization techniques, including the use of GAC and ion exchange resins, are essential for achieving the desired ICUMSA color standards.

Evaporation and Concentration

The evaporation and concentration process is a pivotal step in the sugar refining journey, transforming dilute sugar liquor into a concentrated syrup. This process is crucial for the production of high-quality refined sugar.

Multiple-Effect Evaporation in Sugar Processing

Multiple-effect evaporation is a technique used to concentrate sugar liquor efficiently. This method involves a series of evaporators, where the vapor from one evaporator is used to heat the next, thus saving energy. The use of multiple-effect evaporation significantly reduces the energy required for the evaporation process, making it a cost-effective and environmentally friendly option.

As stated by industry experts, “Multiple-effect evaporation systems are designed to optimize energy use while maximizing the concentration of sugar liquor.” This technique is widely adopted in modern sugar refineries due to its efficiency and effectiveness.

Energy Efficiency in Evaporation Systems | Sugar Refining Process

Energy efficiency is a critical consideration in the evaporation process. By utilizing multiple-effect evaporation, sugar refineries can significantly reduce their energy consumption. The key to achieving energy efficiency lies in the optimal design and operation of the evaporation system, ensuring that the maximum amount of vapor is utilized with minimal energy loss.

- Proper maintenance of equipment to prevent energy leaks

- Optimization of the number of effects based on the specific requirements of the refinery

- Use of advanced technologies to monitor and control the evaporation process

Syrup Quality Control Parameters | Sugar Refining Process

Ensuring the quality of the syrup produced during evaporation is crucial. Key quality control parameters include the concentration of sucrose, the presence of impurities, and the color of the syrup. Regular monitoring and adjustment of the evaporation process are necessary to maintain the desired syrup quality.

“The quality of the syrup is directly related to the efficiency of the evaporation process and the quality of the sugar liquor being processed.”

By focusing on these aspects, sugar refineries can produce high-quality refined sugar that meets the required standards.

Crystallization in the Sugar Refining Process

Crystallization is a critical step in the sugar refining process, transforming sugar syrup into crystalline sugar. This process is fundamental to producing high-quality sugar that meets consumer and industrial standards.

Vacuum Pan Crystallization | Sugar Refining Process

Vacuum pan crystallization is a widely used method in the sugar industry for crystallizing sugar syrup. The process involves heating the sugar syrup in a vacuum pan to create a supersaturated solution, which is then seeded with sugar crystals to initiate crystallization.

Key aspects of vacuum pan crystallization include:

- Operating under vacuum conditions to lower the boiling point of the sugar syrup

- Precise temperature control to optimize crystallization

- Monitoring the supersaturation level to ensure optimal crystal formation

Seeding Techniques for Crystal Formation

Seeding techniques play a crucial role in initiating and controlling the crystallization process. The introduction of seed crystals into the supersaturated sugar syrup provides nucleation sites for crystal growth.

Effective seeding techniques involve:

- Using finely ground sugar as seed material

- Controlling the amount of seed added to achieve the desired crystal size

- Timing the seeding to coincide with optimal supersaturation levels

Controlling Crystal Size and Uniformity

Controlling the size and uniformity of sugar crystals is essential for producing high-quality sugar. Factors influencing crystal size include the degree of supersaturation, temperature, and the presence of impurities.

| Factor | Effect on Crystal Size |

|---|---|

| Supersaturation Level | Higher supersaturation leads to smaller crystals |

| Temperature | Higher temperatures can increase crystal growth rate |

| Impurities | Presence of impurities can inhibit crystal growth or cause irregular shapes |

By carefully controlling these factors and employing effective seeding techniques, sugar refiners can produce sugar crystals of consistent size and quality.

Separation and Purification

After crystallization, the next critical step in sugar refining is the separation and purification of sugar crystals from the mother liquor. This stage is crucial for producing high-quality refined sugar.

Centrifugation Methods

Centrifugation is the primary method used to separate sugar crystals from the syrup. Batch centrifuges and continuous centrifuges are the two main types employed in sugar refineries. Batch centrifuges are used for smaller batches and offer flexibility, while continuous centrifuges are ideal for large-scale operations, providing a consistent and efficient separation process.

The centrifugation process involves spinning the massecuite (the mixture of sugar crystals and syrup) at high speeds, forcing the syrup out through a perforated basket, leaving the sugar crystals behind. This step is critical for removing impurities and achieving the desired sugar quality.

Washing and Purification of Sugar Crystals

After centrifugation, the sugar crystals are washed to remove any remaining impurities. This is typically done using a small amount of water or steam, which helps to dissolve and remove the impurities without significantly affecting the sugar crystals.

The washing process is crucial for achieving high-purity sugar. The quality of the wash water and the efficiency of the washing process directly impact the final quality of the refined sugar. Advanced washing techniques and equipment are used to minimize water usage while maximizing purity.

Recovery of Sugar from Molasses

Molasses, the syrup separated during centrifugation, still contains a significant amount of sugar. Various techniques are employed to recover this sugar, including further crystallization, chromatographic separation, and other advanced technologies.

Recovering sugar from molasses not only improves the overall yield of the refining process but also reduces waste. The recovered sugar is then reprocessed and added to the main sugar stream, contributing to the overall efficiency and profitability of the sugar refinery.

By optimizing centrifugation, washing, and molasses sugar recovery, sugar refineries can significantly enhance their operational efficiency and produce high-quality refined sugar that meets consumer demands.

Drying and Conditioning

Drying and conditioning are pivotal processes in sugar refining that determine the suitability of sugar for storage and distribution. These final stages are crucial in ensuring the quality and longevity of the sugar product.

Sugar Drying Technologies

Sugar drying is a critical step that removes excess moisture from the sugar crystals, preventing caking and lumping during storage. Various technologies are employed in sugar drying, including:

- Rotary dryers: These are commonly used for their efficiency and ability to handle large quantities.

- Fluid bed dryers: Known for their gentle drying process, which helps preserve the quality of sugar crystals.

- Pneumatic dryers: Utilized for their rapid drying capabilities and compact design.

Conditioning for Optimal Storage

Conditioning involves allowing the dried sugar to stabilize in a controlled environment. This process is essential for achieving a uniform moisture content throughout the sugar batch, which is vital for optimal storage.

Effective conditioning helps in:

- Reducing the risk of caking and lumping.

- Maintaining the quality of sugar during long-term storage.

- Ensuring consistent product quality for distribution.

| Conditioning Parameter | Importance | Optimal Range |

|---|---|---|

| Temperature | Controls the rate of moisture equilibration | 20-30°C |

| Humidity | Affects the final moisture content of sugar | 60-70% RH |

| Time | Ensures thorough stabilization of sugar | 24-48 hours |

Preventing Caking and Lumping

Caking and lumping are significant issues in sugar storage, often resulting from improper drying and conditioning. To prevent these problems, refineries employ several strategies:

- Using anticaking agents to coat sugar crystals.

- Implementing precise drying and conditioning protocols.

- Maintaining optimal storage conditions.

By focusing on these aspects, sugar refineries can significantly improve the quality and shelf life of their products, ensuring they meet consumer expectations and regulatory standards.

Quality Control in Sugar Refining

Ensuring the quality of refined sugar is paramount, involving various tests and adherence to international standards. Quality control is a multifaceted process that begins with the receipt of raw sugar and continues through every stage of the refining process.

Polarity Degree Measurement

The polarity degree of refined sugar is a critical quality parameter. It is measured using a polarimeter, an instrument that determines the optical rotation of sugar solutions. Accurate polarity measurement is essential for assessing the purity and quality of the final product.

Physical and Chemical Testing Methods

Various physical and chemical testing methods are employed to ensure the quality of refined sugar. These include:

- Moisture content analysis

- Granulation and particle size distribution

- Color measurement using ICUMSA (International Commission for Uniform Methods of Sugar Analysis) standards

- Chemical tests for impurities such as ash, sulfur dioxide, and heavy metals

Regular testing ensures that the refined sugar meets the required standards for both industrial and consumer use.

| Test Parameter | Method | Acceptable Limit |

|---|---|---|

| Moisture Content | Gravimetric Analysis | < 0.1% |

| ICUMSA Color | Spectrophotometry | < 45 IU |

| Ash Content | Gravimetric Analysis | < 0.05% |

Codex Standards for Sugars

The Codex Alimentarius Commission sets international standards for sugars, including refined sugar. These standards cover various aspects, such as:

“The Codex Standard for Sugars provides specifications for sugars, including white sugar, refined sugar, and other types, ensuring their quality and safety for consumption worldwide.”

Adhering to Codex standards is crucial for sugar refineries to ensure their products are compliant with international regulations, facilitating global trade.

Safety and Regulatory Considerations

The sugar refining industry must navigate a complex landscape of safety and regulatory requirements to ensure a safe working environment and compliant products.

FSMA Preventive Controls for Sugar Plants

The Food Safety Modernization Act (FSMA) has introduced significant changes to the way sugar plants operate, emphasizing preventive controls to minimize risks. Preventive controls are measures taken to prevent hazards that could impact food safety. In sugar refining, this includes controls for biological, chemical, and physical hazards.

Implementing FSMA preventive controls involves several key steps, including:

- Conducting a hazard analysis to identify potential risks

- Implementing controls to mitigate these risks

- Monitoring these controls to ensure their effectiveness

- Maintaining records of these processes

Combustible Sugar Dust OSHA Regulations

Combustible sugar dust poses a significant risk in sugar refineries, as it can lead to explosions if not properly managed. The Occupational Safety and Health Administration (OSHA) has established regulations to mitigate this risk, including requirements for dust control, explosion protection, and employee training.

| OSHA Regulation | Description |

|---|---|

| Dust Control | Measures to prevent the accumulation of combustible dust |

| Explosion Protection | Use of explosion-proof equipment and venting systems |

| Employee Training | Training employees on the risks associated with combustible dust and safety procedures |

Food Safety Management in Sugar Refineries

Effective food safety management is critical in sugar refineries to ensure the production of safe, high-quality sugar. This involves implementing a comprehensive food safety plan that includes:

Good Manufacturing Practices (GMPs) are fundamental to maintaining a clean and safe production environment. This includes proper cleaning and sanitation procedures, pest control, and employee hygiene practices.

A robust food safety management system also involves regular monitoring and testing to ensure compliance with regulatory standards. This includes testing for contaminants and ensuring that all equipment is properly maintained.

By-Products and Sustainability

The sugar refining process generates several valuable by-products, with refiner’s molasses being one of the most significant. This thick, dark liquid is rich in sugars and other compounds, making it a valuable resource for various industries.

Uses and Applications of Refiner’s Molasses

Refiner’s molasses is utilized in several applications, including:

- Animal feed production

- Ethanol production

- Biogas generation

- Production of various chemicals

The versatility of refiner’s molasses stems from its composition, which includes a mix of fermentable sugars and other nutrients. This makes it an ideal substrate for fermentation processes.

Waste Management in Sugar Refining

Effective waste management is crucial in sugar refining to minimize environmental impact. Strategies include:

- Recycling water within the refining process

- Utilizing by-products like molasses and bagasse

- Implementing waste reduction techniques

By adopting these strategies, sugar refineries can significantly reduce their waste output and environmental footprint.

Sustainable Practices in Modern Sugar Refineries

Modern sugar refineries are adopting various sustainable practices, including:

- Energy-efficient equipment

- Renewable energy sources

- Water conservation measures

These practices not only reduce the environmental impact of sugar refining but also contribute to the industry’s long-term viability.

By focusing on by-products and sustainability, the sugar refining industry is moving towards a more environmentally friendly and economically viable future.

At The End of: Sugar Refining Process

The sugar refining process is a complex series of steps that transform raw sugar into white crystals. This process involves multiple stages, including affination, clarification, decolorization, evaporation, crystallization, separation, and drying.

Throughout these stages, various technologies are employed to remove impurities and achieve the desired quality. Quality control measures, such as measuring the polarity degree and ICUMSA color, ensure the final product meets international standards.

The sugar refining industry also prioritizes safety and sustainability, implementing practices like waste management and energy-efficient systems. By understanding the sugar refining process, manufacturers can optimize production and minimize environmental impact.

In conclusion, the sugar manufacturing process is a multifaceted operation that requires careful attention to detail and a commitment to quality and sustainability. As the industry continues to evolve, advancements in technology will play a crucial role in shaping the future of sugar refining.

FAQ

What is the purpose of affination in sugar refining?

Affination is the first step in sugar refining, aimed at removing impurities from raw sugar crystals, preparing them for further refining.

How is decolorization achieved in sugar refining?

Decolorization is achieved through techniques such as using granular activated carbon and ion exchange resins to remove color from the sugar liquor, resulting in white sugar that meets ICUMSA color standards.

What is the role of crystallization in sugar refining?

Crystallization is a critical step where sugar crystals are formed in vacuum pans, and seeding techniques are used to control crystal size and uniformity, producing high-quality sugar crystals.

Why is refined sugar important in global cuisine?

Refined sugar plays a significant role in baking and cooking, affecting the flavor and texture of various food products, and is a staple ingredient in many cuisines worldwide.

How does the quality of sugar affect the flavor and texture of food products?

The quality of sugar, including its purity, crystal size, and uniformity, can significantly impact the flavor and texture of food products, making quality control crucial in sugar refining.

What is the difference between a sugar mill and a sugar refinery?

A sugar mill is where raw sugar is produced from sugarcane or beets, while a sugar refinery is a separate facility where raw sugar is refined into white sugar, involving different processes and equipment.

What are the main by-products of sugar refining?

One of the main by-products of sugar refining is refiner’s molasses, which has various applications, including animal feed and industrial uses.

How is sugar refining regulated?

Sugar refining is subject to various regulations, including FSMA preventive controls and OSHA regulations regarding combustible sugar dust, to ensure food safety and worker safety.

What is the significance of Codex standards for sugars?

Codex standards for sugars provide a global benchmark for the quality and safety of sugar products, guiding sugar refineries in their quality control processes.

How is energy efficiency achieved in sugar refining?

Energy efficiency in sugar refining is achieved through technologies such as multiple-effect evaporation systems, which minimize energy consumption while maximizing syrup concentration.

Conclusion of: Sugar Refining Process

What this guide covers (and why it matters)

The sugar refining process transforms mixed-color, semi-purified raw sugar into consistent, food-grade white crystals used across the U.S. food industry; understanding each major step helps engineers, buyers, and QA teams align on quality, safety, and cost. Sugar Association — Refining & Processing

Raw sugar 101: a starting point, not a finished food

In the sugar refining process, raw cane sugar (and partially refined beet sugar) arrives with residual molasses, color bodies, ash, and plant residues; these impurities must be stripped and separated before the product can be sold as white granulated sugar. Sugar Association — Cane Refining Overview (Infographic)

Step 0 — Receiving, sampling, and specs

Before wet operations begin in the sugar refining process, incoming lots are sampled and analyzed for color, polarity (sucrose purity), ash, and moisture; setting correct clarification and decolorization targets depends on these measurements and on standardized test methods. ICUMSA — Specifications & Standards

Step 1 — Affination: washing the crystals

The sugar refining process often starts with affination, where warm, high-purity syrup (magma) softens and dissolves the molasses film on raw crystals; a centrifuge then separates cleaner crystals from the syrup to prepare for melting. Encyclopædia Britannica — Affination

Step 2 — Melting: creating a uniform melt liquor

Next in the sugar refining process, washed crystals are dissolved to a controlled-strength “melt liquor,” with pH and °Brix tuned for downstream clarification, color removal, and crystallization efficiency. SKIL (Sugar Knowledge Intl.) — How Sugar is Refined

Step 3 — Clarification by phosphatation (option A)

Many cane refineries in the sugar refining process dose phosphoric acid and lime to form calcium phosphate flocs; these trap nonsugars that are then floated and skimmed in a clarifier, yielding clearer liquor for polishing and decolorization. Encyclopædia Britannica — Phosphatation

Step 4 — Clarification by carbonatation (option B)

Alternatively, the sugar refining process may use carbonatation, where CO2 is bubbled through lime-treated liquor to precipitate fine calcium carbonate; the solids carry off impurities and are removed by filtration. Encyclopædia Britannica — Carbonatation

Step 5 — Polishing filtration

To protect downstream equipment in the sugar refining process, refineries run the clarified stream through polishing filters that remove residual fines before carbon beds, ion-exchange columns, evaporators, and vacuum pans. Encyclopædia Britannica — Clarification

Step 6 — Decolorization: choosing the right route

Color bodies (melanoidins, caramels, polyphenols) drive the biggest visual difference in the sugar refining process; sites typically remove them using granular activated carbon (GAC), bone char (decreasingly common), and/or ion-exchange resins, traded off for efficacy, cost, and sustainability. SKIL — Decolorization in Refining

Decolorization via activated carbon

When the sugar refining process uses GAC, tall adsorber columns capture colored organics; carbon can be thermally regenerated, and performance is well documented for food streams like refined sugar liquors. USDA AMS — Activated Charcoal Technical Report (2024)

Decolorization via ion-exchange resins

Resin systems in the sugar refining process (often strong/weak base anion resins in stages) remove colorants and ionic impurities with low pressure drop, and can reduce operating costs compared with traditional carbon trains. Purolite — Cane Sugar Refining with Resins (Technical Paper)

About bone char and “vegan” sugar

Some legacy refineries in the sugar refining process used bone char for decolorization; many U.S. producers emphasize activated carbon or resin instead—information relevant to “vegan sugar” buyers and labeling. U.S. Sugar — Refining & Activated Carbon Filtration

Step 7 — Evaporation: concentrating the liquor

Multiple-effect evaporators cut steam use by reusing vapor heat, a key energy lever in the sugar refining process; the goal is a stable, high-solids “thick liquor” that crystallizes efficiently. Nordzucker — Sugar Production Stages

Step 8 — Crystallization: controlled growth in vacuum pans

Vacuum pans allow the sugar refining process to boil at lower temperatures while operators seed and manage supersaturation for uniform crystal size, brightness, and yield across A, B, and C strikes. Encyclopædia Britannica — Crystallization

Step 9 — Centrifugation: brightening the crystals

High-speed centrifugals separate crystals from mother liquor in the sugar refining process; brief syrup or water sprays can further brighten granules before drying and conditioning. Sugar Association — Spin/Centrifuge Step (Infographic)

Step 10 — Drying, conditioning, and storage

Fluid-bed or rotary dryers finish the sugar refining process by reducing moisture to low, stable levels and conditioning the crystal surface to prevent caking and ensure free-flow during packaging and distribution. SKIL — Drying & Finishing

Final finishing — screening, packaging, and shelf life

After the sugar refining process finishes drying, screens sort granules to commercial sizes; properly stored granulated sugar has an exceptionally long shelf life due to its very low water activity. Domino Sugar — Product FAQs

Quality metrics: color (ICUMSA), polarity, ash, moisture

Finished quality from the sugar refining process is typically reported as ICUMSA color (IU), °Z polarity (sucrose purity), conductivity ash, and moisture; alignment on definitions and methods avoids spec disputes. ICUMSA — ICUMSA Color Definition

Aligning on product definitions and specs

To benchmark outputs of the sugar refining process, many buyers reference the Codex Standard for Sugars (CXS 212-1999), which outlines characteristics for white sugar and helps harmonize trade and labeling. USDA — Codex Standard for Sugars (CXS 212-1999)

Food safety programs: CGMPs and preventive controls

Although low water activity limits microbial growth, the sugar refining process still requires CGMPs and, where applicable, FSMA Preventive Controls (hazard analysis, monitoring, verification) covering foreign material, allergens in packaging areas, and sanitation. FDA — FSMA Preventive Controls for Human Food

Worker safety: combustible dust awareness

Granulated and powdered sugars can form explosible dust clouds; a modern sugar refining process includes housekeeping, dust collection, explosion protection, and training as highlighted in OSHA guidance. OSHA — Combustible Dust Overview

Energy and sustainability considerations

Because evaporation and pan boiling dominate thermal load, the sugar refining process increasingly leans on multiple-effect arrangements, vapor recompression, and renewable fuels to cut CO2 per ton of sugar. Nordzucker — Sustainable Production

Wastewater and effluent management

Water reuse and proper treatment are integral to the sugar refining process; U.S. facilities follow discharge permits and effluent guidelines to manage suspended solids, BOD, and pH before release. EPA — Sugar Processing Effluent Guidelines

Cane vs. beet: where the refining happens

In cane supply chains, raw sugar typically ships to coastal refineries for the full sugar refining process; beet factories are more integrated near farms, but the chemistry of clarification, decolorization, and crystallization is similar. Sugar Association — Sugar Beet Processing Overview

From by-products to value

Mother liquors from the sugar refining process go to recovery crystallization or to molasses streams that feed distilling, fermentation, and animal nutrition markets, improving overall site yield. Sugar Association — Cane Stream & By-Products

Troubleshooting color and purity

When the sugar refining process struggles with ICUMSA color or °Z purity, teams adjust pH/temperature, rotate carbon/resin beds, or verify lab methods against recognized standards to isolate the bottleneck. ICUMSA — Methods Catalogue

Practical tip for buyers and QA

For supplier approval tied to the sugar refining process, request certificates showing ICUMSA color, polarity, ash, moisture, metal detection checks, and a statement of alignment to Codex CXS 212-1999. USDA — Codex CXS 212-1999

Final thought

From affination and melt clarification to decolorization, evaporation, and controlled crystallization, the sugar refining process is a tightly engineered journey that turns a variable raw stream into reliable white crystals for American kitchens and manufacturers. Encyclopædia Britannica — Cane-Sugar Processing Overview

Sources & References

- Sugar Association — Refining & Processing

- Sugar Association — Cane Refining Infographic

- SKIL (Sugar Knowledge Intl.) — How Sugar is Refined

- ICUMSA — Specifications & Standards | ICUMSA — ICUMSA Color Definition | ICUMSA — Methods Catalogue

- Encyclopædia Britannica —Affination | Phosphatation | Carbonatation | Crystallization | Cane-Sugar Overview

- USDA AMS — Activated Charcoal Technical Report (2024)

- Purolite — Cane Sugar Refining with Resins

- U.S. Sugar — Activated Carbon Filtration & Vegan Note

- Nordzucker — Production Stages | Sustainable Production

- FDA — FSMA Preventive Controls

- OSHA — Combustible Dust

- EPA — Sugar Processing Effluent Guidelines

- Domino Sugar — Product FAQs

- Sugar Association — Sugar Beets Processing | Cane Processing & By-Products