Modern shops use advanced tech to keep food fresh and safe. Picking the right solutions ensures that items stay good from the farm to the table. Today, top sellers offer innovative films and trays to stop leaks.

These tough materials are vital for protecting goods against leaks and environmental damage. Professional meat packaging companies focus on strong seals to meet high safety standards. This ensures that every product remains wholesome for the consumer.

By picking efficient firms, shops can cut waste and please buyers. High-performance barrier lidding and skin films create a secure environment for delicate items. Choosing the right partner is the first step toward long-term success in the industry.

Key Takeaways

- Durability and seal integrity prevent leaks in protein products.

- Innovative lidding films extend the shelf life of fresh items.

- Trays provide structural support and enhance visual appeal.

- Reliable vendors help reduce food waste and operational costs.

- Modern materials protect against oxygen and moisture ingress.

- Skin systems offer a premium look for high-end cuts.

Understanding the U.S. Meat Packaging Industry and Market Landscape

The U.S. meat packaging industry is a significant sector within the broader food packaging market. It plays a crucial role in ensuring the safe distribution and preservation of meat products. The industry is driven by consumer demand for fresh and processed meat products, as well as advancements in packaging technology.

The market size of the U.S. meat packaging industry is substantial and is expected to continue growing. According to market projections, the U.S. meat packaging market is anticipated to reach USD 85.49 billion by 2032, growing at a CAGR of 6.49%.

Market Size: USD 85.49 Billion by 2032 with 6.49% CAGR

The significant market size can be attributed to the large consumption of meat products in the U.S. The demand for effective and efficient packaging solutions that maintain product freshness and safety is a key driver of this growth. Factors such as increasing consumer preference for convenience foods and the rise in demand for packaged meat products are contributing to the expansion of the market.

Fresh Meat Packaging Market Segments and Growth Drivers

The fresh meat packaging market can be segmented based on the type of packaging material, such as films, trays, and absorbent pads. The growth drivers in this market include the increasing demand for fresh meat packaging solutions that extend shelf life and maintain product quality. Additionally, consumer preferences for sustainable and eco-friendly packaging are influencing the development of new packaging materials and designs.

Key growth drivers include:

- Increasing demand for convenience and packaged foods

- Advancements in packaging technology

- Growing consumer awareness of food safety and quality

- Rise in demand for sustainable packaging solutions

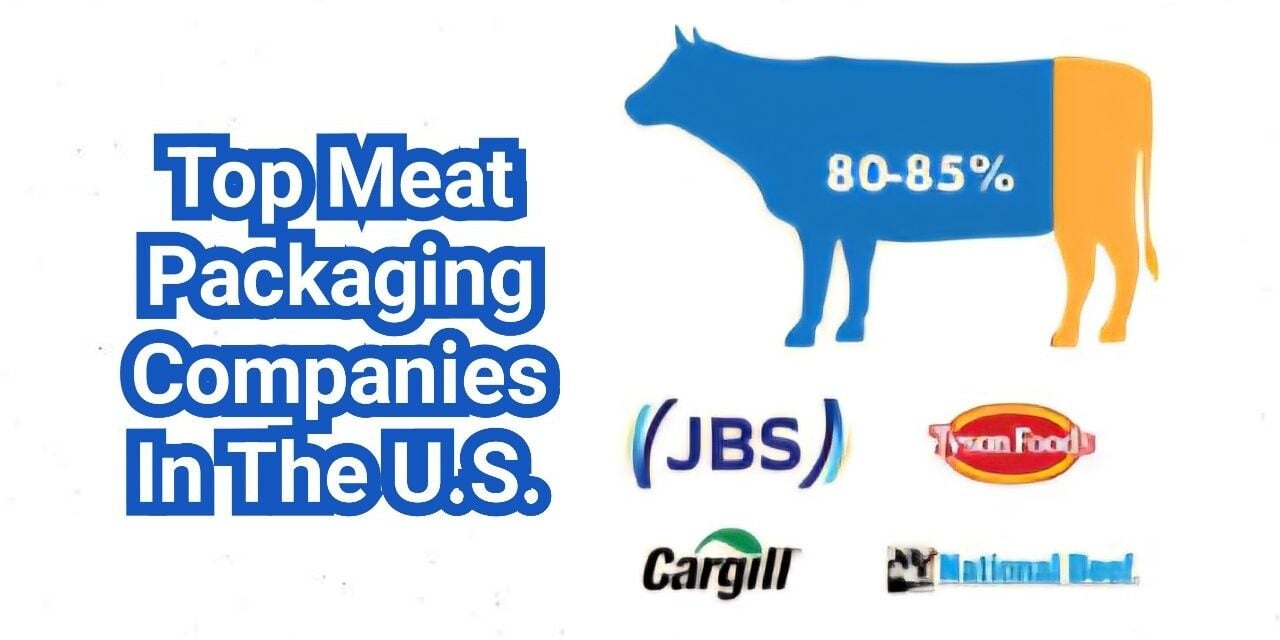

Industry Concentration and Top Market Players

The U.S. meat packaging industry is characterized by a moderate level of concentration, with several major players competing for market share. Top market players include companies such as Amcor plc, Sealed Air Corporation, and Berry Global Group Inc. These companies are known for their innovative packaging solutions and strong distribution networks.

The competitive landscape is marked by a mix of large multinational corporations and smaller, specialized firms. The industry is expected to continue evolving, with companies focusing on developing sustainable packaging solutions and improving their product offerings to meet changing consumer demands.

How to Assess Your Meat Packaging Material Requirements

To determine the right meat packaging materials, you need to evaluate your specific product needs and distribution conditions. Assessing your packaging material requirements is crucial for ensuring the quality, safety, and profitability of your meat products.

Effective meat packaging involves several key considerations, including product type, preservation needs, shelf life, distribution conditions, and budget parameters. By carefully evaluating these factors, you can select the most appropriate packaging solutions for your business.

Step 1: Identify Product Type and Preservation Needs

The type of meat product you are packaging plays a significant role in determining your packaging requirements. Different products have unique preservation needs that must be addressed through appropriate packaging materials and techniques.

- Fresh meat products require packaging that maintains freshness and prevents contamination.

- Cured or processed meats may need packaging that provides specific barrier properties to maintain flavor and texture.

- Products with high fat content may require packaging with enhanced grease resistance.

Understanding the specific preservation needs of your product is essential for selecting the right packaging materials. For example, products that are prone to oxidation may require packaging with high oxygen barrier properties.

Step 2: Determine Shelf Life and Distribution Conditions

Shelf life and distribution conditions are critical factors in determining your packaging requirements. Products with longer shelf lives or those that are distributed over long distances may require more robust packaging solutions.

Consider the following factors when evaluating shelf life and distribution conditions:

- Storage temperature and humidity conditions

- Handling and transportation conditions

- Exposure to light or other environmental factors

By understanding these factors, you can select packaging materials that will protect your products throughout their entire distribution chain.

Step 3: Calculate Volume Requirements and Budget Parameters

Finally, it’s essential to calculate your volume requirements and establish budget parameters for your packaging materials. This involves determining the quantity of packaging materials needed to meet your production demands while staying within your budget.

Consider the following when calculating volume requirements and budget parameters:

- Production volume and packaging material quantity

- Packaging material costs and supplier pricing

- Potential cost savings through economies of scale or alternative packaging solutions

By carefully evaluating these factors, you can optimize your packaging operations and ensure that your meat products are packaged efficiently and effectively.

Selecting Meat Packaging Film for Optimal Food Preservation

The selection of appropriate meat packaging film plays a significant role in ensuring optimal food preservation. The right packaging film can prevent spoilage, maintain product freshness, and ensure compliance with food safety regulations.

Oxygen Barrier Film for Meat: Material Options and Performance

Oxygen barrier films are crucial in meat packaging as they prevent the ingress of oxygen, which can lead to spoilage and degradation of the product. Various materials are used to achieve oxygen barrier properties, including:

- Polyvinylidene chloride (PVDC)

- Ethylene-vinyl alcohol (EVOH)

- Polyamide

- Aluminum oxide-coated films

Each material has its performance characteristics, such as barrier efficiency, clarity, and cost. For instance, PVDC offers excellent oxygen barrier properties but is being phased out in some regions due to environmental concerns.

Meat Lidding Film Selection: Peelable vs. Non-Peelable

Lidding films are used to seal trays containing meat products. The choice between peelable and non-peelable lidding films depends on the product’s requirements and consumer convenience. Peelable films are designed for easy opening, while non-peelable films provide a stronger seal, often used for products that require a higher level of tamper evidence.

PVDC Coating Food Packaging Market and Alternatives

PVDC coating has been widely used in food packaging for its excellent barrier properties. However, due to environmental and health concerns, the industry is shifting towards alternative coatings and materials that offer similar performance without the associated risks. Some alternatives include:

- Acrylic coatings

- Silicon oxide coatings

- Bio-based coatings

Film Thickness and Puncture Resistance Requirements

The thickness and puncture resistance of meat packaging film are critical factors that influence its performance. Thicker films generally offer better puncture resistance but may increase costs and environmental impact. Manufacturers must balance these factors to achieve optimal packaging performance.

Choosing the Right Meat Tray and Lidding Systems

Effective meat packaging relies heavily on the selection of the right tray and lidding system. The choice of tray and lidding film can significantly impact product freshness, leakage prevention, and overall packaging performance.

Foam Trays vs. Rigid Plastic vs. Fiber-Based Containers

The type of tray used for meat packaging depends on several factors, including product type, distribution conditions, and consumer preferences. Foam trays are commonly used for their cushioning properties and ability to keep meat products fresh. Rigid plastic trays offer durability and can be designed with specific features for product display. Fiber-based containers are gaining popularity due to their sustainability and biodegradability.

Each type of tray has its advantages and disadvantages. For instance, foam trays are lightweight and provide good insulation but may not be as durable as rigid plastic trays. Fiber-based containers offer an eco-friendly alternative but may require additional coating or treatment to ensure barrier properties.

Lidding Film Compatibility and Heat Seal Parameters

Lidding film compatibility with the tray is crucial for ensuring a tight seal and preventing leakage. The lidding film must be compatible with the tray material to achieve optimal heat seal parameters. “The right lidding film can make all the difference in maintaining product freshness and preventing contamination.”

Factors to consider when selecting a lidding film include the type of sealant used, the film’s barrier properties, and its compatibility with the tray material. Heat seal parameters such as temperature, pressure, and dwell time must be optimized to achieve a strong and reliable seal.

Tray Design Features for Product Display and Handling

Tray design plays a significant role in product display and handling. Features such as ventilation holes, drainage channels, and product containment can enhance the overall packaging performance. A well-designed tray can improve product visibility, reduce leakage, and make handling easier for consumers.

When designing a tray, manufacturers should consider factors such as product size and shape, distribution conditions, and consumer preferences. By optimizing tray design, manufacturers can improve the overall packaging efficiency and reduce costs.

Implementing Leak Proof Meat Packaging and Purge Control Solutions

The implementation of leak proof meat packaging and purge control solutions is vital for the meat industry to reduce waste and enhance product safety. Effective packaging not only prevents leakage but also maintains the quality and freshness of the meat products.

Leakage in meat packaging can occur due to various factors, including improper sealing, inadequate absorbency, and poor tray design. Therefore, understanding the causes of leakage and implementing appropriate solutions is crucial.

Understanding Purge in Meat Packaging and Its Impact

Purge refers to the liquid that accumulates in meat packaging, often resulting from the natural juices of the meat. This liquid can compromise the packaging’s integrity and lead to leakage.

Key factors influencing purge include:

- Meat type and quality

- Storage conditions

- Packaging material and design

Understanding purge is essential for developing effective purge control strategies. By managing purge, meat packaging companies can reduce leakage and improve overall product quality.

Selecting and Placing Absorbent Pads for Meat Trays

Absorbent pads play a critical role in managing purge in meat packaging. These pads absorb excess liquid, reducing the risk of leakage and maintaining a clean packaging environment.

When selecting absorbent pads, consider:

- Absorbency capacity

- Material composition

- Size and placement within the tray

Designing Leak Proof Meat Packaging with Proper Sealing

Proper sealing is essential for preventing leakage in meat packaging. This involves selecting the right lidding film and ensuring a tight seal around the tray.

Key considerations for leak proof sealing include:

- Lidding film material and thickness

- Sealing temperature and pressure

- Tray design and geometry

Tray Geometry and Drainage Channels for Fluid Management

The design of the meat tray significantly impacts fluid management and leakage prevention. Trays with appropriate geometry and drainage channels can effectively manage purge and reduce leakage.

Effective tray design features include:

- Ribs and ridges for fluid direction

- Drainage channels for excess liquid

- Sufficient depth to contain purge

Troubleshooting Tray Sealing Problems and Solutions

Effective tray sealing is crucial for maintaining the integrity of meat products. Tray sealing problems can lead to significant losses in the meat packaging industry, making it essential to identify and address issues promptly.

The tray sealing process involves several critical factors, including temperature, pressure, and dwell time. When these factors are not optimized, it can result in seal failure, compromising the product’s safety and freshness.

Common Seal Failure Modes: Leakers, Peelers, and Weak Seals

Seal failure can occur in various forms, including leakers, peelers, and weak seals. Leakers are seals that are not fully closed, allowing air or contaminants to enter the package. Peelers refer to seals that are not strong enough, causing the seal to peel apart during handling or storage. Weak seals are those that lack the necessary strength to maintain the package’s integrity.

- Leakers: Caused by insufficient pressure or temperature during the sealing process.

- Peelers: Often result from inadequate dwell time or improper sealant material.

- Weak Seals: Can be due to a variety of factors, including contamination, incorrect sealing parameters, or material defects.

Adjusting Temperature, Pressure, and Dwell Time

To achieve a reliable seal, it is crucial to adjust the sealing parameters: temperature, pressure, and dwell time. The optimal settings depend on the type of tray and lidding material used.

Adjusting these parameters requires a thorough understanding of the materials involved and the sealing equipment. For instance, increasing the temperature can improve the seal strength, but excessive heat can damage the material.

- Temperature: Ensure the sealant layer is melted and forms a strong bond.

- Pressure: Apply sufficient pressure to ensure good contact between the tray and lidding film.

- Dwell Time: Allow enough time for the seal to form and cool.

Contamination Prevention and Die Maintenance | Meat Packaging Companies

Contamination is a significant risk factor for seal failure. Preventing contamination involves maintaining a clean environment and ensuring that the sealing dies are free from debris.

Regular die maintenance is essential to prevent wear and tear that can affect the seal quality. This includes cleaning the dies regularly and replacing them when necessary.

By understanding the common seal failure modes and adjusting the sealing parameters, meat packaging companies can significantly reduce the incidence of tray sealing problems. Implementing contamination prevention measures and maintaining the sealing equipment are also crucial steps in ensuring the integrity of the sealed trays.

Performing Seal Integrity Testing for Food Packaging Quality Control

Seal integrity testing is a vital component of quality control in the food packaging industry. Ensuring that packaging seals are secure and leak-free is critical for maintaining product freshness, preventing contamination, and complying with regulatory requirements.

Importance of Seal Integrity Testing

Seal integrity testing helps to identify potential packaging issues before they become major problems. By verifying the strength and integrity of seals, manufacturers can reduce the risk of product leakage, contamination, and spoilage. This, in turn, helps to protect brand reputation and minimize the financial losses associated with product recalls and waste.

ASTM F88 Seal Strength Testing: Protocol and Equipment | Meat Packaging Companies

The ASTM F88 standard test method is used to determine the seal strength of packaging materials. This test involves measuring the force required to separate the sealed layers of a package. The test protocol includes preparing samples, conditioning them to the required temperature and humidity, and then testing the seal strength using a tensile testing machine.

Key Equipment for ASTM F88 Testing:

- Tensile testing machine

- Seal strength test fixture

- Sample preparation equipment

ASTM F2096 Bubble Leak Test Method for Package Integrity

The ASTM F2096 standard test method involves pressurizing a package underwater to detect leaks. This test is particularly useful for detecting gross leaks in packaging. The test protocol includes submerging the package in water, applying internal pressure, and observing for bubbles that indicate leakage.

Establishing Testing Frequency and Acceptance Criteria | Meat Packaging Companies

To ensure effective quality control, it is essential to establish a regular testing schedule and clear acceptance criteria for seal integrity testing. The testing frequency will depend on factors such as production volume, packaging material, and regulatory requirements. Acceptance criteria should be based on industry standards, regulatory requirements, and the manufacturer’s quality standards.

Best Practices for Seal Integrity Testing:

- Regularly review and update testing protocols to ensure compliance with changing regulatory requirements.

- Use a combination of testing methods to ensure comprehensive evaluation of seal integrity.

- Train personnel on testing procedures and equipment operation.

Implementing Vacuum Packaging for Meat Products

The implementation of vacuum packaging has revolutionized the meat industry by enhancing food safety and shelf life. By removing air from the packaging, vacuum packaging prevents the growth of microorganisms, thereby reducing spoilage and maintaining product freshness.

Shelf Life and Food Safety Benefits | Meat Packaging Companies

Vacuum packaging offers significant benefits in terms of shelf life extension and food safety. By minimizing the oxygen available for microbial growth, vacuum packaging effectively reduces the risk of contamination and spoilage. This method is particularly beneficial for meat products, which are highly perishable.

The removal of air also prevents the oxidation of fats, which can lead to off-flavors and rancidity. As a result, vacuum packaging helps maintain the quality and freshness of meat products throughout the supply chain.

Selecting the Right Vacuum Packaging Film and Pouches

The choice of vacuum packaging film and pouches is critical to the effectiveness of the packaging process. The film must have adequate barrier properties to prevent oxygen ingress and moisture loss. Common materials used include polyamide, polyethylene, and polyvinylidene chloride (PVDC), often in multi-layer constructions to achieve the desired barrier properties.

When selecting vacuum packaging pouches, considerations include the size, shape, and material compatibility with the meat product. Pouches must be durable enough to withstand the vacuum process and subsequent handling.

Chamber vs. Nozzle Vacuum Systems

There are two primary types of vacuum systems used in meat packaging: chamber and nozzle vacuum systems. Chamber vacuum machines are widely used for their ability to achieve high vacuum levels and are suitable for a variety of product types and sizes.

Nozzle vacuum systems, on the other hand, are often used for pre-made pouches and offer flexibility in packaging different product sizes. The choice between these systems depends on the specific requirements of the operation, including product type, production volume, and packaging format.

Deploying Modified Atmosphere Packaging for Fresh Meat

Deploying modified atmosphere packaging (MAP) for fresh meat products is a sophisticated approach that involves precise control over the packaging atmosphere to enhance product longevity. This technique is crucial in the fresh meat industry as it significantly extends shelf life, maintains product quality, and reduces waste.

MAP Gas Mix for Fresh Meat: Optimal CO2, O2, and N2 Ratios

The gas mix used in MAP for fresh meat is critical and typically involves a combination of CO2, O2, and N2. The optimal ratio of these gases depends on the type of meat, its fat content, and the desired shelf life. For instance, high CO2 levels are effective in inhibiting bacterial growth, while O2 is necessary to maintain the meat’s natural color.

- CO2: Inhibits microbial growth and is typically used at high concentrations (20-30%).

- O2: Maintains the red color of meat and is usually kept at lower levels (0-5% for red meat to prevent oxidation).

- N2: Acts as a filler gas to prevent package collapse and is generally used to make up the remainder of the gas mix.

For example, a common gas mix for red meat might include 20-30% CO2, 70-80% O2, and 0-10% N2, though this can vary based on specific product requirements.

High-Barrier Film Requirements for MAP Applications | Meat Packaging Companies

High-barrier films are essential for MAP applications as they prevent the exchange of gases between the inside of the package and the external environment. These films must have low oxygen transmission rates (OTR) and low water vapor transmission rates (WVTR) to maintain the desired atmosphere inside the package.

The selection of high-barrier films involves considering factors such as:

- Material: Common materials include PET, PVC, and EVOH, often used in multilayer constructions.

- Thickness: The thickness of the film affects its barrier properties and puncture resistance.

- Sealability: The film must be sealable to the tray or other packaging components.

Equipment Selection and Gas Flushing Techniques | Meat Packaging Companies

The effectiveness of MAP also depends on the equipment used for gas flushing and packaging. Equipment selection involves choosing the right type of gas flushing system, such as snorkel or chamber machines, and ensuring that it is compatible with the packaging film and tray.

Gas flushing techniques are critical for achieving the desired atmosphere inside the package. This involves:

- Pre-flushing the package with the desired gas mix.

- Ensuring adequate gas flow rates to achieve the required gas composition.

- Monitoring and controlling the gas composition to maintain consistency.

By carefully selecting the gas mix, high-barrier films, and appropriate equipment, manufacturers can effectively deploy MAP for fresh meat products, enhancing their shelf life and maintaining product quality.

Navigating FSIS Label Approval and Net Weight Compliance

Meat producers must navigate complex regulations to ensure compliance with FSIS label approval and net weight requirements. The Food Safety and Inspection Service (FSIS) regulates the labeling of meat products to ensure consumer safety and transparency. Compliance with these regulations is crucial for maintaining public trust and avoiding costly penalties.

The FSIS label approval process is a critical component of regulatory compliance. Meat producers must submit their labels for approval before using them on products. This process involves ensuring that labels contain accurate information about the product, including its name, ingredients, and handling instructions.

FSIS Label Approval Process for Meat Products

The FSIS label approval process involves several steps:

- Submission of label applications to the FSIS

- Review of label content for compliance with regulations

- Approval or rejection of label applications

Label content must include the product name, inspection legend, handling instructions, and ingredient list. Ensuring that labels are accurate and compliant is essential for avoiding delays in the approval process.

Net Weight Compliance and Tare Weight Management | Meat Packaging Companies

Net weight compliance is another critical aspect of regulatory adherence. Meat producers must ensure that their packaging accurately reflects the net weight of the product. This involves managing tare weight, which is the weight of the packaging material.

To achieve net weight compliance, producers must:

- Accurately measure the net weight of their products

- Minimize variations in packaging weight

- Regularly audit their packaging processes

Working with Suppliers to Meet USDA Regulations | Meat Packaging Companies

Meat producers must work closely with their suppliers to ensure compliance with USDA regulations. This includes sourcing packaging materials that meet FSIS requirements and ensuring that suppliers adhere to relevant guidelines.

By partnering with compliant suppliers, meat producers can reduce the risk of non-compliance and maintain a smooth label approval process. Regular communication and auditing of suppliers are essential for ensuring regulatory adherence.

Evaluating Sustainable Meat Packaging Options and PFAS Concerns

With the rising awareness of environmental issues, sustainable meat packaging options are gaining traction. The meat packaging industry is under increasing pressure to adopt eco-friendly solutions that not only reduce environmental impact but also maintain food safety and product quality.

Recyclable and Compostable Packaging Materials

The shift towards sustainability in meat packaging involves exploring recyclable and compostable materials. Recyclable materials, such as certain plastics and papers, can significantly reduce waste by being reused. Compostable materials, on the other hand, are designed to break down into non-toxic components that can act as fertilizers.

Key characteristics of recyclable and compostable packaging materials include:

- Reduced environmental footprint

- Compliance with regulatory standards

- Compatibility with existing packaging machinery

- Consumer acceptance and education

PFAS in Food Packaging Overview: Risks and Regulations | Meat Packaging Companies

Per- and Polyfluoroalkyl Substances (PFAS) have been widely used in food packaging for their grease-resistant properties. However, concerns over their potential health and environmental risks have led to increased regulatory scrutiny.

Key risks associated with PFAS include:

- Persistence in the environment

- Bioaccumulation in humans and wildlife

- Potential links to health issues

Regulations around PFAS are evolving, with some countries banning their use in food packaging. Companies must stay informed about these changes to ensure compliance.

| Material | Sustainability Features | Regulatory Status |

|---|---|---|

| Recyclable PET | Recyclable, reduces waste | Compliant with FDA regulations |

| Compostable PLA | Breaks down into non-toxic components | Meets ASTM D6400 standards |

| PFAS-free coatings | Environmentally friendly alternative | Compliant with emerging PFAS regulations |

Balancing Sustainability with Food Safety and Shelf Life

Achieving a balance between sustainability, food safety, and shelf life is crucial. Sustainable packaging solutions must not compromise the primary function of packaging: to protect the product.

Strategies for balancing these factors include:

- Material innovation to enhance barrier properties

- Optimizing packaging design for minimal material use

- Ensuring compliance with food safety regulations

By adopting a holistic approach to packaging, companies can meet consumer demands for sustainability while maintaining the integrity of their products.

Top Meat Packaging Companies and Major Suppliers in the U.S.

The U.S. meat packaging industry is dominated by a few key players that offer a wide range of innovative solutions. These companies are crucial for providing the necessary packaging materials and technologies that ensure food safety, extend shelf life, and enhance product presentation.

Amcor plc: Flexible Films and Barrier Solutions

Amcor plc is a leading global supplier of packaging solutions, including flexible films and barrier solutions for the meat packaging industry. Their products are designed to provide high-barrier protection, preventing the ingress of oxygen and moisture that can spoil meat products.

As Amcor’s CEO, Ron Delia, once said,

“Our focus is on creating packaging that is not only functional but also sustainable.”

This commitment to sustainability is reflected in their range of eco-friendly packaging options.

Sealed Air Corporation: Cryovac Brand and Vacuum Packaging

Sealed Air Corporation is another major player in the U.S. meat packaging market, known for its Cryovac brand of vacuum packaging solutions. Their products are designed to preserve the freshness of meat products by removing air from the packaging.

The Cryovac brand has been at the forefront of vacuum packaging technology, providing solutions that extend the shelf life of meat products and reduce food waste.

Berry Global Group Inc.: Trays, Films, and Containers

Berry Global Group Inc. is a leading supplier of packaging solutions, including trays, films, and containers for the meat industry. Their products are designed to be functional and sustainable, meeting the needs of meat processors and consumers alike.

Berry Global’s product portfolio includes a range of innovative packaging solutions that cater to the diverse needs of the meat packaging industry.

Pactiv Evergreen Inc.: Foam and Rigid Tray Systems | Meat Packaging Companies

Pactiv Evergreen Inc. is a major supplier of foam and rigid tray systems for the meat packaging industry. Their products are designed to provide protection and presentation for meat products, ensuring that they remain fresh and appealing to consumers.

| Company | Key Products/Services | Notable Features |

|---|---|---|

| Amcor plc | Flexible Films, Barrier Solutions | High-barrier protection, Sustainable options |

| Sealed Air Corporation | Cryovac Brand, Vacuum Packaging | Preserves freshness, Reduces food waste |

| Berry Global Group Inc. | Trays, Films, Containers | Functional, Sustainable |

| Pactiv Evergreen Inc. | Foam and Rigid Tray Systems | Protection, Presentation |

How to Compare Meat Packaging Suppliers and Create an Evaluation Matrix

Meat packaging suppliers can be compared effectively by developing a comprehensive evaluation matrix that covers technical, quality, and logistical aspects. This systematic approach enables meat processors to identify the best supplier for their specific needs.

Defining Technical Requirements and Specifications | Meat Packaging Companies

The first step in comparing meat packaging suppliers is to clearly define your technical requirements and specifications. This involves identifying the type of packaging needed, such as vacuum packaging films, modified atmosphere packaging (MAP) films, or specific tray and lidding systems. Consider factors like barrier properties, sealability, and puncture resistance to ensure the packaging meets your product’s preservation needs.

- Determine the required material composition and thickness.

- Specify any necessary certifications, such as FDA compliance or sustainability credentials.

- Outline performance requirements, including shelf life and distribution conditions.

Requesting Samples and Conducting Performance Testing | Meat Packaging Companies

Once technical requirements are defined, request samples from potential suppliers to conduct performance testing. This step is crucial for assessing the packaging’s functionality and compatibility with your products. Key tests may include:

- Seal strength testing to ensure the packaging remains sealed during distribution.

- Puncture resistance testing to assess durability.

- Barrier property testing to verify the packaging’s ability to preserve freshness.

Evaluating Certifications, Food Safety, and Quality Systems

Evaluating a supplier’s certifications and quality systems is vital for ensuring compliance with food safety regulations and industry standards. Look for suppliers with:

- Certifications such as ISO 22000 or SQF.

- A robust quality management system that includes regular audits and continuous improvement processes.

- Compliance with relevant food safety regulations, such as FSMA in the U.S.

Comparing Pricing, MOQs, and Lead Times | Meat Packaging Companies

Finally, compare the pricing, minimum order quantities (MOQs), and lead times offered by different suppliers. Consider not only the cost per unit but also the total cost of ownership, including factors like:

- Tooling and setup costs.

- Inventory management and storage costs.

- The impact of lead times on your production scheduling and inventory levels.

By systematically evaluating these aspects and creating a comprehensive evaluation matrix, meat processors can make informed decisions when selecting a meat packaging supplier.

Partnering with Custom Meat Packaging Companies for Specialized Solutions

Custom meat packaging companies offer tailored solutions that address the unique needs of meat products, from preservation to presentation. In an industry where product differentiation and brand identity are crucial, custom packaging can be a significant competitive advantage.

Identifying When Custom Packaging is Necessary

Determining the need for custom meat packaging involves assessing the specific requirements of your product. Factors such as product type, distribution conditions, and branding needs play a crucial role in this decision. For instance, products with unique shapes or those requiring specific preservation methods may necessitate custom packaging solutions.

Key considerations for custom packaging include:

- Product dimensions and geometry

- Preservation and shelf-life requirements

- Branding and display needs

- Regulatory compliance

Collaborating on Design, Branding, and Functional Requirements

Effective collaboration with custom meat packaging companies involves clearly communicating your design, branding, and functional requirements. This includes providing detailed specifications regarding material preferences, barrier properties, and printing needs.

A well-designed packaging solution not only protects the product but also enhances brand visibility and consumer appeal. Companies like Amcor plc and Sealed Air Corporation offer a range of customizable options that can be tailored to meet specific needs.

Prototyping, Testing, and Scaling to Production Volumes

The process of developing custom meat packaging involves several stages, from prototyping and testing to scaling up to production volumes. Prototyping allows for the evaluation of packaging performance and makes it possible to identify and address any potential issues before full-scale production begins.

| Stage | Description | Key Activities |

|---|---|---|

| Prototyping | Creating initial packaging samples | Design finalization, Material selection |

| Testing | Evaluating packaging performance | Seal integrity testing, Leak testing |

| Production | Scaling up to commercial volumes | Tooling development, Quality control implementation |

By partnering with experienced custom meat packaging companies, producers can ensure that their packaging meets both functional and branding requirements, ultimately enhancing product appeal and reducing potential losses due to packaging failures.

At The End of: Meat Packaging Companies

Effective meat packaging is crucial for maintaining food safety and extending shelf life. The U.S. meat packaging industry offers a range of solutions, from films and trays to leak prevention and vacuum packaging systems. Suppliers like Amcor plc, Sealed Air Corporation, Berry Global Group Inc., and Pactiv Evergreen Inc. provide innovative packaging solutions that cater to diverse needs.

By understanding the market landscape, assessing material requirements, and selecting the right packaging solutions, businesses can ensure optimal product preservation and display. Implementing leak proof packaging, troubleshooting tray sealing problems, and performing seal integrity testing are critical steps in maintaining packaging quality.

As the industry continues to evolve, sustainable packaging options and PFAS concerns are becoming increasingly important. By partnering with the right suppliers and staying informed about regulatory requirements, businesses can navigate the complexities of meat packaging and maintain a competitive edge.

FAQ

Who are the leading meat packaging companies in the U.S. currently dominating the market?

The U.S. meat packaging industry is led by several global powerhouses that provide advanced solutions for food safety and shelf life. Key market leaders include Amcor plc, Sealed Air Corporation (renowned for its Cryovac brand), Berry Global Group, Inc., and Pactiv Evergreen Inc. Other significant players contributing to the projected USD 85.49 billion market include Sonoco Products Company, Huhtamaki Oyj, and Winpak Ltd. These companies provide everything from flexible films to rigid tray systems for major processors like Tyson Foods, JBS N.V., and Cargill.

What are the primary benefits of using Modified Atmosphere Packaging (MAP) for fresh meat?

Modified atmosphere packaging for meat is essential for extending shelf life while maintaining the “bloomed” red color of fresh beef. By using a specific MAP gas mix for fresh meat—typically a combination of Oxygen (O2) to maintain color, Carbon Dioxide (CO2) to inhibit bacterial growth, and Nitrogen (N2) as a filler—suppliers can significantly delay spoilage. This process requires high-barrier film and specialized meat tray and lidding systems to ensure the gas mixture remains consistent throughout the distribution chain.

How can processors prevent leaks and manage fluid in fresh meat trays?

Achieving leak proof meat packaging involves a combination of high-quality meat packaging materials and proper purge control. Purge control in meat packaging is typically managed by using absorbent pads for meat trays that soak up excess moisture, preventing bacterial growth and enhancing visual appeal. Additionally, optimizing tray geometry with drainage channels and ensuring seal integrity through correct heat seal parameters are critical steps in preventing “leakers” during transport.

What is the difference between vacuum packaging and MAP for food preservation?

Vacuum packaging for meat involves removing all air from the package before sealing, which is ideal for frozen meat, beef jerky, and certain wholesale cuts. It uses a high-performance vacuum packaging film or pouch to create a tight fit that prevents freezer burn. In contrast, MAP replaces the air with a protective gas mixture, which is better for retail fresh meat packaging where the visual appearance of the product (the red color) is a primary selling point. Both methods are vital for food safety and extending the fresh meat packaging market reach.

What testing standards are used to ensure meat packaging seal integrity?

To maintain food safety and quality, companies perform rigorous seal integrity testing for food packaging. The two most common protocols are ASTM F88 seal strength testing, which measures the force required to separate a heat seal, and the ASTM F2096 bubble leak test, which identifies holes or defects by submerging the package in water. Consistent testing helps identify tray sealing problems and solutions, such as adjusting dwell time or pressure to prevent weak seals.

Why is an oxygen barrier film important for meat products?

An oxygen barrier film for meat is critical because oxygen is the primary driver of oxidative rancidity and aerobic bacterial growth. Many meat packaging suppliers utilize materials like PVDC coating or EVOH layers to create a barrier. High-performance meat lidding film must prevent oxygen ingress to protect the flavor and color of the product, particularly for items with high fat content or those intended for long-term storage.

What regulations govern meat packaging labels and weights in the U.S.?

All meat products must comply with USDA regulations. This includes obtaining FSIS label approval for meat products to ensure that all claims, ingredients, and nutritional facts are accurate. Furthermore, net weight compliance in meat packaging is strictly monitored; processors must account for “tare weight” (the weight of the meat tray, absorbent pads, and meat packaging film) to ensure consumers are only paying for the actual meat content.

What are the latest sustainable meat packaging options available to reduce environmental impact?

The industry is shifting toward sustainable meat packaging options, including recyclable and compostable packaging materials and fiber-based trays from companies like Cascades Inc. or Smurfit Kappa Group. A major focus in the current fresh meat packaging industry is the elimination of PFAS in food packaging. Many meat packaging manufacturers are now developing PFAS-free barrier coatings to meet new state and federal environmental safety regulations without compromising shelf life.

How do I choose between different meat packaging suppliers?

When evaluating meat packaging suppliers, you should create a matrix comparing technical requirements, food safety certifications (such as SQF or BRC), and pricing. It is important to request samples of meat packaging supplies to test puncture resistance and seal strength on your specific machinery. Leading meat packaging companies in usa like Winpak or Berry Global often provide on-site technical support to help optimize your meat packaging equipment and reduce waste.

When should a business consider custom meat packaging solutions or co-packers?

Custom meat packaging services are necessary when a product has a unique shape, requires specialized branding, or has specific food preservation needs that off-the-shelf meat trays cannot meet. For smaller brands or specialized products like artisanal snacks, partnering with beef jerky co packers or custom meat packaging companies allows for professional-grade vacuum packaging and labeling without the high capital investment of purchasing meat processing and packaging machinery in-house.

Do meat packaging companies need “USDA approval” for packaging itself?

Packaging materials are typically supported through food-contact compliance documentation, while the finished product label pathway depends on how your product is regulated and marketed. Treat it as two tracks: materials compliance plus label compliance, and require suppliers to support both with documentation and version control. FSIS: Labeling Overview and Generic Label Approval (PDF)

What’s the simplest way to reduce leaks fast?

Standardize the sealing zone: keep flanges dry, reduce purge at the seal area, and match tray/lidding combinations that seal reliably across normal production variation. A fast win is also controlling refrigerator storage and case handling so juices don’t spread even if a pack is imperfect. FSIS: Preventing Cross-Contamination

Can I use recycled plastics in meat packaging?

It can be possible depending on the application and the supplier’s process controls, but you should require clear documentation about the recycling process and intended food-contact use conditions. Ask for written support and limitations, and avoid assumptions based on generic “PCR” marketing language. FDA: Recycled Plastics in Food Packaging

Why do net weight complaints happen when packs purge?

Net weight rules and verification approaches focus on declared contents, and purge can create customer confusion even when labeling is compliant. Reduce complaints by matching pad performance to purge reality, tightening fill-weight control, and aligning QA checks to recognized net content practices. NIST: Handbook 133 (Net Contents of Packaged Goods)

How do I know if my integrity testing approach is “enough”?

Match the test to the failure mode: gross leaks need different tools than microleaks, and your sampling plan should reflect product risk, distribution length, and complaint history. Strong meat packaging companies help you define practical limits and train operators so testing catches real problems without becoming busywork. ASTM: Packaging Standards and Publications

Conclusion of: Meat Packaging Companies

Why packaging choices matter more than you think

Meat packaging companies influence far more than “what the product looks like” on the shelf—they shape shelf life, purge control, seal reliability, label compliance, and how confidently buyers handle raw product at home. The right packaging system also reduces messy leaks in transit, helps maintain color and freshness, and protects margins by cutting rework and claims. FSIS: Meat and Poultry Packaging Materials

When you compare options, it helps to separate three goals: food-contact safety (materials and inks), package performance (barrier + seals), and real-world handling (cold chain and leak prevention). If any one of these is weak, you’ll see it as fogging, off-odors, short shelf life, “blown” packs, or customer complaints about juices in the bag. FDA: Food Packaging and Food Contact Substances

What meat packaging suppliers usually provide (and what they don’t)

Most meat packaging companies fall into a few buckets: flexible-film converters (rollstock, shrink bags, lidding), rigid packaging manufacturers (trays, tubs, lids), and distributors who bundle multiple components plus service. Your job is to figure out whether you need “components only” or a packaging partner who can also help with line trials, sealing parameters, troubleshooting, and supplier-managed inventory. PMMI: Packaging and Processing Industry Hub

In the U.S., packaging decisions often tie to regional supply realities—plant density, cold storage availability, and transportation distance—because longer lanes amplify leak risk and temperature abuse. A supplier comparison should reflect your route-to-market (local retail vs. regional wholesale vs. nationwide shipping), not just the cheapest film quote. USDA: Meat and Poultry Supply Chain

The U.S. regulatory map: FSIS vs. FDA and why it affects your specs

For most meat and poultry, the label and container requirements sit under USDA-FSIS oversight, so packaging changes can indirectly trigger label layout, net weight expectations, and required statements depending on product type. That’s why your packaging spec sheet should include intended use (raw vs. RTE), storage state (refrigerated/frozen), and how the product will be sold (random weight vs. fixed weight). 9 CFR Part 317: Labeling, Marking Devices, and Containers

At the same time, many packaging materials (films, coatings, adhesives, and certain additives) are regulated as food contact substances, and your supplier should be able to provide documentation that the structure is suitable for the intended conditions of use. Treat this like a “must-have” in procurement: no documentation, no approval—especially when heat, fat, or long storage increases the chance of migration concerns. FDA: Food Ingredients and Packaging

A practical way to manage this is to request a one-page compliance packet for each packaging SKU you buy: resin/structure description, food-contact regulatory basis, and any temperature/food-type limitations. This documentation is part of what separates professional meat packaging companies from “commodity-only” vendors who can’t support audits or customer requirements. FDA: Packaging & Food Contact Substances (FCS)

Documentation you should demand before you run a single trial

Ask for a clear statement of how the material is authorized (for example, references to applicable CFR sections or Food Contact Notifications) and whether any additives are subject to limitations. For co-packed or private-label programs, this paperwork often gets reviewed by retailers, third-party auditors, and corporate QA—so make it part of your onboarding checklist, not a last-minute scramble. FDA: Inventory of Effective Food Contact Substance Notifications

Also require clarity on adhesives, inks, and laminations—especially for printed lidding and rollstock—because set-off, scuffing, and ink transfer risks rise when packages rub during distribution. A smart RFQ from meat packaging companies includes performance targets (seal range, hot tack, puncture) plus manufacturing controls (lot traceability, CoA/CoC availability, and change-notification expectations). 21 CFR Part 174: Indirect Food Additives (General)

For printed packs, make sure your supplier can confirm that adhesives and coatings are suitable for packaging use under the intended conditions, and that the print system is designed for food packaging applications (not general industrial labeling). If a vendor can’t explain the food-contact basis for their constructions, you’re taking on unnecessary risk. 21 CFR 175.105: Adhesives

Films and lidding: what to compare beyond “thickness”

Flexible materials are not just “plastic wrap”—they’re engineered stacks of layers that balance barrier, sealability, toughness, and machinability. When evaluating meat packaging companies for films, ask them to describe the sealant layer (what seals to what), the barrier layer (what blocks oxygen), and the abuse layer (what resists puncture and scuff). 21 CFR Part 177: Indirect Food Additives (Polymers)

Barrier matters because oxygen drives oxidation and color changes, while moisture and aromas affect perceived freshness. Even when two films “look the same,” different barrier properties can change shelf life and retail appearance—so compare oxygen barrier targets for your exact product and display conditions, not generic claims. Foods (MDPI): Packaging Barrier Properties and Meat Quality

Seal performance is the real profit line: many leaks come from contamination in the seal area (fat, purge, spice) or from seals outside the optimal temperature/pressure/dwell window. A serious evaluation of meat packaging companies includes seal-strength testing, seal-failure mode notes, and repeatability across production lots. ASTM F88/F88M: Seal Strength of Flexible Barrier Materials

Trays, pads, and purge management: the “leak prevention” foundation

Tray selection is usually a tradeoff between rigidity, sealing surface quality, and how the tray behaves under cold temperatures and stacking loads. If you’re comparing materials, remember that resin identification markings are about identifying the plastic, not automatically proving it’s recyclable everywhere—so don’t build marketing claims from symbols alone. ASTM D7611: Resin Identification Codes

Purge control isn’t only a “mess” issue—excess purge can affect presentation, perceived freshness, and net weight complaints when customers compare label weight to what they see in the tray. When meat packaging companies recommend pads and tray geometries, insist on tests that simulate your real conditions: time on ice, display time, and case-pack compression. FSIS: Net Weight Guidance

A simple but powerful leak-control step is to design for gravity: keep raw protein on the lowest shelf in coolers, use trays with stable sealing flanges, and choose pads that wick quickly without shedding fibers. Your packaging should support safe handling so juices don’t leak onto other foods during storage and transport. CDC: Preventing Food Poisoning (Storage and Cross-Contamination)

Sanitation, condensation, and the hidden causes of seal failures

Leaks often spike when sanitation and handling drift: wet flanges, sanitizer residues, poor condensation control, or inconsistent product temperature can all disrupt sealing. If you’re running in a regulated facility, your packaging program should align with sanitation SOP expectations, because “clean enough to seal consistently” is also “clean enough to pass verification.” 9 CFR Part 416: Sanitation

In practice, the easiest win is to control the sealing zone like a critical interface: dry the flange, reduce splashes, standardize fill weights, and train operators to spot “fatty seal” conditions early. Strong meat packaging companies will help you set line checks (visual + pull tests) and define when to stop the line before bad product accumulates. 9 CFR Part 417: HACCP Systems

Package integrity testing: pick tests that match your real failure modes

For trays and pouches, a “bubble leak” style approach can be useful for catching gross leaks and comparing setups during trials. When you select a verification method, make sure it’s sensitive enough for your risk tolerance and that your team can run it consistently, because inconsistent testing defeats the purpose. ASTM F2096: Detecting Gross Leaks in Packaging (Bubble Test)

Channel leaks—tiny pathways in the seal—are a common culprit when seals look fine but packs still fail later. If your operation uses porous/nonporous combinations or you suspect channeling from contamination, dye-penetration style methods can help locate where the seal is being compromised. ASTM F1929: Detecting Seal Leaks by Dye Penetration

When you need nondestructive testing for ongoing QA (so you don’t destroy every sample), vacuum-decay methods can detect smaller leaks than basic “looks good” checks. This is where meat packaging companies with strong technical service can stand out—helping you define test limits, sampling plans, and corrective actions that actually reduce customer complaints. ASTM F2338: Nondestructive Leak Detection by Vacuum Decay

Modified atmosphere vs. vacuum: choose based on color, shelf life, and your risk controls

Modified atmosphere packaging (MAP) is often used to support retail appearance and delay spoilage, but the “best” gas mix depends on product, display goals, and microbial controls. When meat packaging companies propose MAP, ask for a clear rationale: how the gas mix supports color, how it affects purge, and what it means for shelf-life validation in your temperature reality. Pork Gateway: MAP Microbial Control and Quality (PDF)

Vacuum packaging can reduce oxygen exposure but it also changes appearance, and it can magnify the impact of temperature abuse if your cold chain isn’t disciplined. Your process and packaging must work together—especially for ground products and high-risk items—because the safe outcome depends on time/temperature control and correct consumer handling. FSIS: Safe Minimum Internal Temperature Chart

For ready-to-eat products that are exposed post-lethality, packaging is part of the control strategy—sealing is not just “quality,” it’s risk management. If you pack or re-pack RTE items, your program should reflect Listeria controls, environmental monitoring expectations, and verified packaging performance. 9 CFR 430.4: Control of Listeria monocytogenes

Supplier comparison: a scorecard that actually predicts performance

A useful scorecard compares suppliers on more than price: regulatory documentation quality, change-notification discipline, technical support, lead times, and consistency across lots. When meat packaging companies bid, ask whether they can support your label pathway (generic vs. sketch approval triggers) and whether they’ll flag when a change could affect your label or claims. FSIS: Guideline for Label Approval (PDF)

Include a “claims reality check” line item: if you sell “fresh,” “natural,” “no antibiotics ever,” or other statements, packaging and labeling must stay truthful and not misleading, and documentation should back up what you print. Strong meat packaging companies will ask about your claims early because it changes how they recommend materials, labeling stock, and version control. FSIS: Meat and Poultry Labeling Terms

Finally, score traceability: can the supplier link every roll, tray, and lidding lot to production dates and raw material lots, and can you link that to finished goods? If your customers require GS1 identifiers, make sure your label and data strategy is compatible from day one. GS1: Global Trade Item Number (GTIN)

Step-by-step: how to source packaging without expensive “trial-and-error”

Step 1 is defining the hazard and quality targets—shelf life, purge tolerance, sealing window, and distribution conditions—then documenting them in your packaging spec. Good meat packaging companies can translate these targets into testable material properties and line settings, but they need your real operating conditions to do it right. eCFR: HACCP Systems (9 CFR Part 417)

Step 2 is structured trials: run at least two material lots, include worst-case conditions (cold product, fatty contamination, peak line speed), and capture failures by type (seal peel, channel leak, puncture, tray crack). Then align receiving and shipping practices with sanitation and temperature controls so you don’t “validate” something that only works in perfect lab-like conditions. FDA: Sanitary Transportation Rule Overview

Step 3 is operationalization: lock the spec, require written change notifications, set incoming QC checks, and define how you’ll quarantine suspect lots. If sustainability goals are part of your brand, evaluate lightweighting, recycled content feasibility, and end-of-life realities with the same discipline you apply to leak prevention. EPA: Sustainable Packaging

Chemicals, PFAS, and “safer by design” decisions

Even when packaging is legally authorized, buyers increasingly ask about “chemicals of concern,” especially in coatings and grease-resistant applications. If your products touch paperboard, wraps, or specialty coatings in secondary packaging, it’s smart to ask your suppliers what they are using and how they manage transitions away from certain chemistries. FDA: Industry Actions End Sales of PFAS Used in U.S. Food Packaging

For operations, “safer by design” also means fewer failures: minimize unnecessary additives, reduce ink coverage where possible, and standardize structures across SKUs to simplify QA. Meat packaging companies that support long-term programs will help you reduce SKUs thoughtfully while protecting performance where it matters (seals, barrier, and abuse resistance). OSHA 1910.147: Lockout/Tagout (Control of Hazardous Energy)

Quick checklist

Use this checklist to evaluate meat packaging companies quickly, then go deeper only with the finalists. BRCGS: Packaging Materials Standard Overview

- Documented food-contact compliance packet for every material SKU

- Clear seal “window” guidance (temperature/pressure/dwell) and contamination tolerance notes

- Barrier targets aligned to your shelf-life goal and retail display conditions

- Tray flange quality and dimensional consistency controls

- Purge-management plan (pad type, placement, absorbency targets, fiber control)

- Package integrity test plan (what test, what limit, what sampling rate)

- Lot traceability and change-notification policy (resin, gauge, additive, ink changes)

- Lead time and safety stock options (including supplier-managed inventory if needed)

- Trial support: on-site/remote troubleshooting and documented trial report format

- Transportation fit: case-pack design, stacking tests, and temperature expectations

Common mistakes to avoid

Most packaging failures come from predictable gaps in process discipline, not from “bad materials,” so build prevention into your program with your meat packaging companies. FSIS: Understanding Food Recalls

- Choosing by thickness only: compare barrier, sealability, and puncture resistance, not gauge alone

- Ignoring seal contamination: design and train for fat/purge control at the flange

- Skipping lot-to-lot trials: validate with multiple lots to avoid “one good roll” bias

- No change-notification rules: require written notice before resin/additive/print changes

- Under-testing distribution: simulate stacking loads, cold temperatures, and handling abuse

- Weak receiving QC: check dimensions, sealability indicators, and damage before use

- Overcomplicating SKUs: too many film/tray variants increases errors and scrap

- Misusing resin codes for marketing: don’t claim recyclability without market reality checks

Costs and ROI snapshot

Packaging cost is usually a mix of materials, downtime, and claims: the lowest unit-price film can be the most expensive if it increases seal failures, scrap, or customer leakage complaints. Many processors find ROI when meat packaging companies help stabilize sealing, reduce rework, and support longer shelf life that lowers markdowns and returns. USDA Rural Development: Value-Added Producer Grants

In practical terms, your biggest cost drivers are often (1) high-barrier structures and printing, (2) tray rigidity and dimensional tolerances, (3) integrity testing labor and scrap, and (4) equipment capability (tray sealer vs. thermoformer vs. vacuum chamber). ROI shows up as fewer leakers per thousand, fewer rejected cases, faster line speeds at stable seal quality, and reduced freight loss from messy claims—especially when financed as part of a broader capacity plan. SBA: 7(a) Loan Program

Final thought

The best results come when you treat packaging as a system—materials, seals, sanitation, labeling, and cold chain—not as a single purchase order line item. If you build a documentation-first comparison and run disciplined trials, meat packaging companies become partners in fewer leaks, stronger compliance, and steadier margins. FSIS: Safe Handling Label Text

Sources & References

- FDA: Inventory of Food Contact Substances Listed in 21 CFR

- FDA: Guidance on Use of Recycled Plastics in Food Packaging

- FDA: Authorized Uses of PFAS in Food Contact Applications

- FDA: Market Phase-Out of PFAS Grease-Proofers

- FSIS: Recalls & Public Health Alerts

- FSIS: Food Product Dating

- FSIS: Guide to Federal Food Labeling Requirements (PDF)

- FSIS: Allergens and Ingredients Guidance (PDF)

- FSIS: Listeria Guidance (Post-Lethality Exposed RTE)

- EPA: Sustainable Materials Management Basics

- FoodSafety.gov: Safe Minimum Internal Temperatures

- USDA AMS: Process Verified Programs

- FSIS: Grants & Financial Options

- GS1: Barcode Standards

- PMMI: Packaging and Predictive Maintenance