Evaluating food manufacturing capabilities is crucial in today’s competitive market. The ability to deliver products on time, maintain high-quality standards, and adapt to changing demands is vital for businesses relying on these services.

Recent studies highlight the importance of reliability assessment in the food industry, where factors like perishability and fluctuating demand pose significant challenges. Companies must assess the capacity and reliability of their partners to ensure smooth operations.

Understanding the key criteria for evaluation is essential for making informed decisions. This article will delve into the critical aspects of assessing food production companies, focusing on capacity, reliability, and on-time delivery.

Key Takeaways

- Understanding the importance of capacity evaluation in food manufacturing.

- Assessing the reliability of food production companies.

- The impact of on-time delivery on business operations.

- Key criteria for evaluating food production companies.

- Best practices for ensuring reliable food manufacturing services.

The Current Landscape of Food Production Companies in the USA

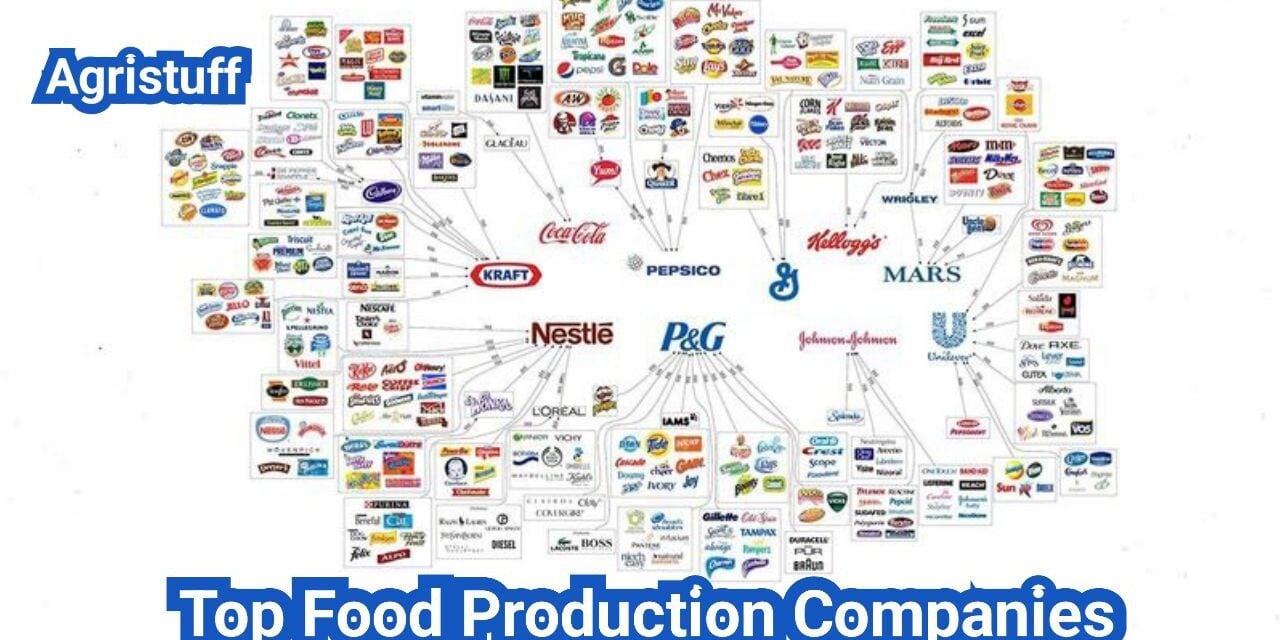

The landscape of food production in the United States is characterized by diversity and challenge. The industry is a significant contributor to the country’s economy, with a wide range of companies operating across different product categories.

Overview of the U.S. Food Manufacturing Industry

The U.S. food manufacturing industry is a substantial sector, employing millions and generating billions of dollars in revenue annually. It encompasses a broad spectrum of activities, from processing and packaging to distribution.

Key statistics highlight the industry’s scale: it accounts for a significant portion of the country’s GDP and is a major employer in many regions.

Types of Food Production Companies

Food production companies in the U.S. can be categorized into several types based on their functions and specialties. These include:

- Co-packers: Companies that provide packaging services for other brands.

- Co-manufacturers: Businesses that manufacture products for other companies.

- Private label manufacturers: Producers that create products sold under another company’s brand.

Current Trends and Market Challenges

The food manufacturing industry is subject to various trends and challenges. Market trends include the increasing demand for organic and sustainable products, as well as the integration of technology in production processes.

Challenges faced by the industry include fluctuating demand, regulatory compliance, and maintaining high delivery reliability. Companies must adapt to these challenges to remain competitive.

Understanding Co-Packers vs. Co-Manufacturers in Food Production

Understanding the nuances between co-packing and co-manufacturing is essential for food producers looking to outsource part or all of their production processes. Both co-packers and co-manufacturers play critical roles in the food industry, but they offer different services and operate under different business models.

Defining Co-Packing and Co-Manufacturing Relationships

Co-packing involves a company hiring a third-party contractor to package their products. This can include labeling, bottling, or boxing the final product. Co-packers typically do not formulate or manufacture the products; they simply prepare them for distribution. On the other hand, co-manufacturing involves a deeper level of collaboration where the contractor is responsible for producing the product according to the client’s specifications, which can include formulation, manufacturing, and sometimes packaging.

The relationship between a food company and its co-packer or co-manufacturer is built on trust, quality control, and mutual benefit. Companies must carefully evaluate potential partners to ensure they meet their quality, quantity, and regulatory compliance needs.

When to Choose Each Option for Your Products

The choice between co-packing and co-manufacturing depends on several factors, including the type of product, production capacity requirements, and the level of control a company wishes to maintain over the manufacturing process. For instance, if a company has a product that is already manufactured but needs packaging, co-packing might be the more cost-effective and efficient choice. Conversely, if a company needs a product to be formulated and manufactured according to specific recipes or standards, co-manufacturing is likely the better option.

Consider the following when deciding:

- Product Complexity: Complex products may require co-manufacturing to ensure quality and consistency.

- Production Volume: High-volume needs might necessitate co-manufacturing capabilities.

- Specialized Equipment: Products requiring specialized equipment for manufacturing might be better suited for co-manufacturing.

Cost Structures and Business Models

The cost structures and business models of co-packers and co-manufacturers can vary significantly. Co-packers typically charge for their services based on the packaging requirements, such as per unit packaging costs. Co-manufacturers, however, may charge based on production volume, formulation complexity, and other manufacturing-related factors. Understanding these cost structures is crucial for food companies to accurately budget and forecast their expenses.

When evaluating potential co-packers or co-manufacturers, it’s essential to consider not just their pricing but also their ability to scale with your business, their quality control measures, and their compliance with food safety regulations. A well-structured partnership can lead to significant benefits, including cost savings, increased efficiency, and improved product quality.

Essential Criteria for Evaluating Food Production Companies

The process of evaluating food production companies involves a comprehensive analysis of their production capabilities, quality control measures, and delivery performance. This assessment is crucial for businesses looking to partner with a reliable food production company that can meet their specific needs and requirements.

Production Capacity Assessment Methods

Evaluating the production capacity of a food production company is vital to ensure they can meet demand. This involves assessing their equipment, technology, and workforce. Key factors include:

- Production line capabilities and limitations

- Equipment maintenance schedules and downtime

- Workforce training and capacity to handle increased production

- Flexibility to adapt to changes in demand

Production capacity assessment should also consider the company’s ability to scale up or down in response to market fluctuations. This can be achieved through:

- Reviewing historical production data

- Assessing their capacity planning strategies

- Evaluating their ability to implement just-in-time production

Quality Control Systems Evaluation

A robust quality control system is essential for ensuring the production of high-quality food products. When evaluating a food production company, it’s crucial to assess their quality control measures, including:

- HACCP (Hazard Analysis and Critical Control Points) implementation

- Good Manufacturing Practices (GMPs) adherence

- Regular auditing and compliance with food safety regulations

- Training programs for quality control personnel

Effective quality control also involves continuous monitoring and improvement of processes. This can be achieved through:

- Regular review of quality control data

- Implementation of corrective actions when necessary

- Continuous training and education for production staff

Reliability Indicators and Red Flags

Reliability is a critical factor when evaluating food production companies. Key reliability indicators include:

- Consistency in meeting production deadlines

- Quality of communication and customer service

- Ability to adapt to changes in demand or specifications

- Transparency in their production processes and challenges

Potential red flags to watch out for include:

- Frequent changes in management or staff

- Lack of transparency in their operations

- Poor communication or unresponsiveness

- History of non-compliance with regulations

On-Time Delivery Track Record Verification

Verifying a food production company’s on-time delivery track record is crucial for ensuring they can meet your business needs. This involves:

- Reviewing their historical delivery performance data

- Assessing their logistics and distribution capabilities

- Evaluating their ability to manage supply chain disruptions

- Checking for any certifications or awards related to delivery performance

On-time delivery is not just about meeting deadlines; it’s also about the condition and accuracy of the delivered products. Therefore, it’s essential to assess their:

- Order fulfillment accuracy

- Product handling and packaging practices

- Ability to track and trace products throughout the supply chain

Developing a Comprehensive Co-Manufacturer Vetting Process

Developing a robust co-manufacturer vetting process is essential for mitigating risks and ensuring compliance with industry standards. This process involves several critical steps that help businesses evaluate potential co-manufacturing partners thoroughly.

Initial Screening Criteria and Questionnaires

The initial screening is a crucial step in the vetting process, allowing companies to quickly identify potential red flags or areas of concern. This stage typically involves creating a comprehensive questionnaire that covers key aspects such as:

- Company history and experience

- Production capabilities and capacity

- Quality control measures

- Certifications and compliance with industry standards

- Financial stability

A well-designed questionnaire helps in gathering essential information about the co-manufacturer’s operations and capabilities, facilitating a more informed decision-making process.

Documentation Review Protocols

Once the initial screening is complete, the next step involves a thorough review of the co-manufacturer’s documentation. This includes examining:

| Document Type | Purpose | Key Elements to Review |

|---|---|---|

| Quality Manual | Outlines quality policies and procedures | Scope, responsibilities, and quality objectives |

| SOPs (Standard Operating Procedures) | Details specific procedures for various operations | Clarity, relevance, and adherence to industry standards |

| Certification Documents | Proof of compliance with industry standards | Validity, scope, and issuing authority |

A thorough documentation review helps in assessing the co-manufacturer’s commitment to quality and compliance.

Site Visit Checklists and Procedures

Conducting site visits is a vital component of the vetting process, providing firsthand insight into the co-manufacturer’s facilities and practices. A comprehensive site visit checklist should cover:

- Facility cleanliness and organization

- Equipment condition and maintenance practices

- Staff training and hygiene practices

- Quality control measures in place

Site visits allow businesses to verify the information gathered during the initial screening and documentation review, providing a more comprehensive understanding of the co-manufacturer’s capabilities.

“A site visit can reveal a lot about a co-manufacturer’s operations and commitment to quality. It’s an opportunity to see firsthand how they manage their facilities and implement their quality control measures.”

Reference Checks and Industry Reputation

The final step in the vetting process involves checking references and assessing the co-manufacturer’s industry reputation. This can be done by:

- Contacting existing or past clients

- Reviewing industry reports and ratings

- Checking for any history of compliance issues or recalls

Reference checks provide valuable insights into the co-manufacturer’s reliability, customer service, and overall performance, helping businesses make a well-informed decision.

By following this comprehensive vetting process, companies can significantly reduce the risks associated with partnering with a co-manufacturer and ensure a successful, compliant partnership.

How to Assess Manufacturing Capacity and Scalability

To ensure efficient operations, food production companies need to assess their manufacturing capacity and scalability regularly. This assessment is crucial for understanding whether current production capabilities can meet existing demand and scale appropriately for future growth.

Equipment Capabilities and Technical Limitations

Evaluating equipment capabilities involves assessing the technical specifications and limitations of the machinery used in production. This includes understanding the maximum throughput, processing speeds, and any technical constraints that could impact production.

Key factors to consider:

- Equipment age and condition

- Maintenance requirements and history

- Compatibility with existing production lines

As noted by industry expert

“The right equipment can significantly enhance production efficiency, but it’s equally important to consider the technical limitations and potential bottlenecks.”

Production Line Efficiency Metrics

Production line efficiency is critical for maximizing output while minimizing waste and reducing costs. Key metrics to evaluate include overall equipment effectiveness (OEE), production cycle time, and throughput rates.

| Metric | Description | Importance |

|---|---|---|

| OEE | Measures equipment effectiveness based on availability, performance, and quality | High |

| Cycle Time | Time taken to complete one production cycle | Medium |

| Throughput Rate | Quantity of products produced within a given timeframe | High |

Capacity Planning and Demand Forecasting

Effective capacity planning involves forecasting future demand and aligning production capacity accordingly. This requires analyzing historical sales data, market trends, and seasonal fluctuations to predict future production needs.

Evaluating Scalability for Future Growth

Scalability is the ability of a production system to increase output in response to rising demand. Evaluating scalability involves assessing whether the current production infrastructure can be expanded or upgraded to meet future needs.

Considerations for scalability:

- Flexibility of production lines

- Availability of resources (labor, materials, equipment)

- Potential for technology upgrades or integration

By carefully assessing manufacturing capacity and scalability, food production companies can ensure they are well-positioned to meet current and future demands efficiently.

Measuring Reliability in Food Production Partners

Reliability in food production partnerships is a multifaceted concept that encompasses various operational and logistical factors. To ensure a stable and efficient supply chain, it’s essential to evaluate the reliability of food production partners comprehensively.

Historical Performance Analysis

One of the primary indicators of a food production partner’s reliability is their historical performance. This involves analyzing their past production records, delivery timelines, and quality control measures. By examining historical data, businesses can identify patterns and trends that may impact future performance.

Key metrics to analyze include:

- Production volume consistency

- On-time delivery rates

- Quality control failure rates

- Customer complaint resolution effectiveness

Staff Turnover and Training Programs

Staff turnover rates and the effectiveness of training programs significantly impact a food production partner’s reliability. High staff turnover can lead to inconsistencies in production quality and potentially compromise food safety standards.

Factors to consider:

- Employee retention rates

- Comprehensiveness of training programs

- Frequency of training updates

- Certification levels of production staff

Maintenance Schedules and Equipment Uptime

Regular maintenance of production equipment is crucial for ensuring continuous operation and preventing unexpected downtime. A reliable food production partner should have a robust maintenance schedule in place.

Key aspects to evaluate:

- Preventive maintenance frequency

- Equipment uptime records

- Spare parts inventory management

- Emergency repair protocols

Contingency Planning and Risk Management

A reliable food production partner should have comprehensive contingency plans in place to address potential disruptions, such as natural disasters, supply chain interruptions, or equipment failures.

Elements of effective contingency planning:

- Risk assessment processes

- Business continuity plans

- Alternative sourcing arrangements

- Crisis management protocols

By thoroughly assessing these aspects, businesses can gain a comprehensive understanding of their food production partners’ reliability and make informed decisions about their partnerships.

Evaluating On-Time Delivery and OTIF Performance

On-time delivery and OTIF performance are critical metrics that food production companies must evaluate to ensure reliability. In the competitive food industry, maintaining a high level of on-time delivery is crucial for customer satisfaction and loyalty.

On-Time In-Full (OTIF) Measurement Standards

OTIF is a key performance indicator that measures the ability of a supplier to deliver products on time and in full. To evaluate OTIF performance, companies should establish clear measurement standards. This includes defining what constitutes “on-time” and “in-full” deliveries. Accurate data collection and analysis are essential for assessing OTIF performance.

Implementing a robust OTIF measurement system involves tracking delivery dates, quantities, and any discrepancies. Companies can use this data to identify trends and areas for improvement in their supply chain.

Supply Chain Integration Capabilities | Food Production Companies

Effective supply chain integration is vital for achieving high OTIF performance. This involves collaborating closely with suppliers, manufacturers, and logistics providers to ensure seamless coordination. Advanced supply chain visibility tools can significantly enhance integration capabilities.

By integrating their supply chains, companies can better anticipate and respond to potential disruptions, thereby improving their on-time delivery rates.

Logistics Network Assessment | Food Production Companies

A well-structured logistics network is critical for on-time delivery. Companies should assess their logistics networks to identify potential bottlenecks and areas for optimization. This includes evaluating transportation modes, warehouse locations, and distribution strategies.

Optimizing logistics networks can lead to reduced delivery times and improved OTIF performance. Companies should consider using data analytics and simulation models to identify the most efficient logistics configurations.

Order Fulfillment Process Evaluation | Food Production Companies

The order fulfillment process plays a crucial role in determining OTIF performance. Companies should evaluate their order fulfillment processes to ensure they are efficient and accurate. This includes assessing order processing times, inventory management practices, and picking and packing procedures.

Streamlining order fulfillment processes can significantly improve on-time delivery rates. Companies should implement best practices such as automation and lean manufacturing principles to enhance their order fulfillment capabilities.

Food Safety Compliance and Certification Requirements

Food safety is a top priority in the food industry, governed by stringent regulations and certification requirements. Ensuring compliance with these regulations is crucial for maintaining consumer trust and avoiding legal repercussions.

FSMA Compliance and Preventive Controls

The Food Safety Modernization Act (FSMA) represents a significant shift in food safety regulation, focusing on preventing contamination rather than responding to it. Key aspects of FSMA compliance include:

- Implementing preventive controls to identify and mitigate potential hazards

- Maintaining detailed records of these controls and their effectiveness

- Ensuring that all personnel are adequately trained in food safety practices

Preventive controls are a critical component, requiring a thorough understanding of potential hazards and the implementation of effective mitigation strategies.

Third-Party Certifications (SQF, BRC, GFSI) | Food Production Companies

Third-party certifications such as SQF, BRC, and GFSI play a vital role in verifying a company’s commitment to food safety. These certifications involve:

- Rigorous audits to ensure compliance with international food safety standards

- Continuous monitoring and improvement of food safety practices

- Transparency in operations and a commitment to quality

Companies often pursue these certifications to enhance their credibility and access to global markets.

HACCP Implementation and Validation Documentation

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to identifying and controlling hazards in the food production process. Effective HACCP implementation involves:

- Conducting a thorough hazard analysis

- Identifying critical control points and establishing critical limits

- Implementing monitoring procedures and corrective actions

Validation and verification of HACCP plans are essential to ensure their effectiveness and compliance with regulatory requirements.

PCQI Requirements and Food Safety Plan Evaluation

The Preventive Controls Qualified Individual (PCQI) is a critical role under FSMA, requiring individuals to be trained and qualified in developing and implementing preventive controls. A PCQI must:

- Develop and implement a comprehensive food safety plan

- Ensure that the plan is regularly reviewed and updated

- Oversee the training of personnel in food safety practices

Evaluating the food safety plan is an ongoing process, requiring continuous monitoring and improvement to maintain compliance and ensure food safety.

Traceability Systems and Recall Readiness

In the food industry, having robust traceability systems and recall plans in place is essential for managing risk and adhering to FSMA 204 requirements. Traceability is not just about compliance; it’s a critical component of a comprehensive food safety strategy.

FSMA 204 Traceability Requirements Implementation

The Food Safety Modernization Act (FSMA) 204 rule mandates enhanced traceability for certain food products. Implementing these requirements involves:

- Identifying critical tracking events and key data elements

- Maintaining detailed records of these events and data

- Ensuring the ability to share this information with regulators within specified timeframes

Effective implementation requires a thorough understanding of the supply chain and the use of technology to track and record critical data.

Recall Plan Components and Testing | Food Production Companies

A comprehensive recall plan is crucial for effective recall execution. Key components include:

- Clear roles and responsibilities

- Detailed product information

- Communication protocols for stakeholders

- Procedures for product retrieval and disposal

Regular testing of the recall plan through mock recalls helps identify areas for improvement and ensures readiness in case of an actual recall.

Mock Recall Performance Metrics

Conducting mock recalls and analyzing their performance is vital for assessing recall readiness. Key metrics to track include:

- Time taken to identify and segregate affected products

- Accuracy of information during the recall process

- Effectiveness of communication across the supply chain

Analyzing these metrics helps in refining the recall plan and improving overall recall readiness.

Traceability Technology Solutions Assessment | Food Production Companies

Leveraging technology is critical for enhancing traceability. When assessing traceability technology solutions, consider:

- Integration capabilities with existing systems

- Data accuracy and reliability

- User-friendliness and training requirements

- Scalability to accommodate future needs

Choosing the right technology can significantly improve traceability and recall efficiency.

Sanitation and Allergen Control Program Evaluation

Sanitation and allergen control are critical components of a food safety plan, requiring thorough evaluation. Effective sanitation and allergen control programs are essential for preventing contamination and ensuring the safety of food products.

Sanitation Standard Operating Procedures (SSOPs)

Sanitation Standard Operating Procedures (SSOPs) are detailed protocols that outline the steps necessary for maintaining cleanliness and hygiene in food production facilities. Effective SSOPs are crucial for preventing the spread of pathogens and contaminants. These procedures should cover all aspects of sanitation, including cleaning schedules, methods, and responsibilities.

To evaluate SSOPs, one must assess their comprehensiveness, implementation, and adherence to regulatory requirements. This includes reviewing documentation, observing cleaning practices, and verifying that all personnel understand and follow the procedures.

Allergen Control Program Requirements | Food Production Companies

An effective allergen control program is vital for protecting consumers with food allergies. This program should include procedures for identifying, handling, and controlling allergenic ingredients. Key components include allergen labeling, segregation of allergenic ingredients, and training for personnel on allergen handling.

Evaluating an allergen control program involves assessing its ability to prevent cross-contamination, the accuracy of allergen labeling, and the effectiveness of training programs. Regular audits and testing can help ensure compliance with regulatory requirements and industry standards.

Environmental Monitoring Programs

Environmental monitoring programs are designed to detect and control pathogens in the production environment. These programs involve regular sampling and testing of surfaces, equipment, and air to identify potential contamination risks.

To evaluate an environmental monitoring program, one should assess the sampling strategy, testing methods, and response to positive findings. Effective programs also include corrective actions and preventive measures to mitigate identified risks.

Cleaning Validation Protocols | Food Production Companies

Cleaning validation protocols are essential for ensuring that cleaning procedures effectively remove contaminants and residues from equipment and surfaces. These protocols involve testing and verification to confirm the efficacy of cleaning procedures.

Evaluating cleaning validation protocols requires assessing the methods used for testing, the frequency of validation, and the criteria for determining cleaning effectiveness. Rigorous validation ensures that equipment is properly cleaned and sanitized, reducing the risk of contamination.

Quality Management Systems in Food Manufacturing

In the food manufacturing industry, quality management systems play a crucial role in ensuring product safety and consistency. These systems encompass various processes and procedures that help maintain high-quality standards throughout the production cycle.

Distinguishing Quality Assurance from Quality Control

Quality assurance (QA) and quality control (QC) are two integral components of a quality management system. While often used interchangeably, they have distinct roles. Quality assurance focuses on preventing defects by ensuring processes are in place to maintain quality standards. On the other hand, quality control involves the actual testing and inspection of products to detect any defects or deviations from the standards.

A robust quality management system integrates both QA and QC to ensure a proactive and reactive approach to quality management. This integration is vital for maintaining consumer trust and complying with regulatory requirements.

Implementing Statistical Process Control | Food Production Companies

Statistical Process Control (SPC) is a methodology that uses statistical techniques to monitor and control processes. It helps in detecting variations in the production process, enabling manufacturers to take corrective actions before defects occur. SPC involves the use of control charts to track process parameters and ensure they are within predetermined limits.

- Identify critical control points in the production process.

- Establish control limits based on historical data and regulatory requirements.

- Continuously monitor process parameters and take corrective actions when necessary.

Fostering Continuous Improvement Programs | Food Production Companies

Continuous improvement is a key aspect of a quality management system. It involves regularly assessing processes and implementing changes to enhance efficiency, reduce waste, and improve product quality. Techniques such as Kaizen and Lean manufacturing are commonly used to drive continuous improvement initiatives.

Effective continuous improvement programs rely on employee engagement, data-driven decision-making, and a culture that encourages innovation and learning.

Maintaining Comprehensive Documentation and Record-Keeping

Accurate and comprehensive documentation is essential for a quality management system. It includes records of production processes, quality control checks, and corrective actions taken. Proper documentation helps in tracing the history of a product, facilitating recalls if necessary, and demonstrating compliance with regulatory requirements.

A well-maintained documentation system also supports continuous improvement by providing valuable data for analysis and process optimization.

Creating Effective Supplier Scorecards for Food Manufacturers

The development of comprehensive supplier scorecards is a strategic move for food manufacturers aiming to optimize their supplier management. Supplier scorecards are valuable tools that enable companies to evaluate and manage supplier performance systematically.

Key Performance Indicators (KPIs) Selection | Food Production Companies

Selecting the right KPIs is crucial for an effective supplier scorecard. Food manufacturers should identify KPIs that align with their business objectives and supply chain requirements. Common KPIs include on-time delivery, quality compliance, lead time, and cost competitiveness.

Table: Example KPIs for Supplier Scorecards

| KPI | Description | Weightage |

|---|---|---|

| On-Time Delivery | Percentage of orders delivered on time | 30% |

| Quality Compliance | Number of quality issues reported | 25% |

| Lead Time | Average time taken to deliver orders | 20% |

| Cost Competitiveness | Comparison of supplier costs with market standards | 25% |

Quality and Compliance Scoring Methods | Food Production Companies

Quality and compliance scoring is a critical component of supplier scorecards. Food manufacturers can use various methods to score suppliers, such as rating scales (e.g., 1-5) or percentage-based scoring. The scoring method should be transparent and consistently applied.

Example: A supplier with a high-quality compliance rate might receive a score of 5, while a supplier with frequent quality issues might receive a score of 1.

Performance Review Frequency and Process | Food Production Companies

Regular performance reviews are essential to ensure that suppliers continue to meet the required standards. Food manufacturers should determine the frequency of reviews based on the supplier’s criticality and performance history. The review process should include a thorough analysis of the supplier’s scorecard data and may involve regular meetings or written reports.

Implementing Continuous Improvement Feedback Loops

Continuous improvement is a key aspect of effective supplier management. Food manufacturers should establish feedback loops to communicate with suppliers regarding their performance and areas for improvement. This can involve regular discussions, joint improvement plans, and collaborative problem-solving initiatives.

By implementing these strategies, food manufacturers can create effective supplier scorecards that enhance supplier performance and contribute to the overall success of their operations.

Conducting Comprehensive Food Manufacturing Audits

Conducting comprehensive audits is a critical step in ensuring that food manufacturing operations meet regulatory requirements and industry standards. These audits help identify potential compliance issues, improve quality control, and maintain customer trust.

Developing an Audit Checklist | Food Production Companies

A well-structured audit checklist is essential for thorough food manufacturing audits. This checklist should cover all critical areas, including:

- Facility sanitation and hygiene practices

- Raw material sourcing and supplier management

- Production processes and equipment maintenance

- Labeling and packaging compliance

- Quality control measures and testing protocols

By using a comprehensive checklist, auditors can systematically evaluate each aspect of the manufacturing process, ensuring that no critical areas are overlooked.

Scheduled vs. Surprise Audit Strategies | Food Production Companies

Food manufacturers can choose between scheduled audits and surprise audits, each with its advantages. Scheduled audits allow for preparation and can be less disruptive to operations, while surprise audits can provide a more accurate snapshot of daily practices.

A balanced approach might include both scheduled and surprise audits to ensure ongoing compliance and identify areas for improvement.

Common Compliance Red Flags | Food Production Companies

During audits, several compliance red flags may be identified, including:

- Inadequate sanitation practices or cleaning schedules

- Insufficient training of production staff

- Poor record-keeping or documentation

- Non-compliance with labeling regulations

- Inadequate pest control measures

Recognizing these red flags allows manufacturers to address issues promptly and implement corrective actions.

Post-Audit Action Plans and Follow-up | Food Production Companies

After completing an audit, developing a post-audit action plan is crucial. This plan should outline the necessary corrective actions, assign responsibilities, and set timelines for implementation.

Regular follow-up is essential to ensure that the identified issues are addressed and that the implemented changes are effective. This follow-up may involve additional audits or reviews to verify compliance and continuous improvement.

By conducting comprehensive food manufacturing audits and following up with effective action plans, companies can maintain high standards of quality, ensure regulatory compliance, and build trust with their customers and partners.

Negotiating Contracts and Service Level Agreements

When partnering with food production companies, negotiating contracts and service level agreements is a critical step that demands careful consideration. A well-crafted contract ensures that all parties are aware of their responsibilities, expectations, and obligations, laying the groundwork for a successful and enduring partnership.

Essential Contract Elements for Food Production

A comprehensive contract for food production should include several key elements. These are:

- Clear Scope of Work: Defines the specific services to be provided by the food production company.

- Quality and Compliance Standards: Outlines the quality control measures and regulatory compliance requirements.

- Delivery Terms: Specifies the delivery schedules, including On-Time In-Full (OTIF) expectations.

- Payment Terms: Details the pricing structure, payment schedules, and any incentives or penalties.

Defining Service Level Expectations and Metrics | Food Production Companies

Service level agreements (SLAs) are critical in defining the expected performance levels of the food production company. Key metrics to consider include:

- Production Capacity: The ability to meet demand without compromising quality.

- Quality Control: Measures to ensure consistent product quality.

- On-Time Delivery: Metrics to track and improve delivery performance.

Pricing Models and Cost Structure Considerations

Pricing models can significantly impact the profitability and sustainability of the partnership. Common pricing models include:

- Fixed Pricing: Offers predictability but may not account for fluctuations in raw material costs.

- Cost-Plus Pricing: Allows for adjustments based on actual costs incurred.

Risk Allocation and Liability Provisions | Food Production Companies

Clearly defining risk allocation and liability provisions is essential to protect all parties involved. This includes:

- Indemnification Clauses: Protect against losses due to the other party’s negligence or non-compliance.

- Insurance Requirements: Specifies the types and levels of insurance coverage required.

- Force Majeure: Outlines the procedures for handling unforeseen events that may impact performance.

By carefully negotiating contracts and service level agreements, food production companies can establish strong, mutually beneficial partnerships that drive success and growth.

Building Successful Partnerships with Food Production Companies

Building successful partnerships with food production companies requires a thorough evaluation of their capacity, reliability, and on-time delivery performance. By understanding these critical factors, businesses can establish robust partnerships that drive success in the competitive food industry.

A key aspect of successful partnerships is assessing a food production company’s capacity to meet production demands. This involves evaluating their equipment capabilities, production line efficiency, and scalability for future growth. Companies like General Mills and PepsiCo have demonstrated the importance of capacity planning in maintaining a stable supply chain.

Reliability is another crucial factor in building successful partnerships. This includes evaluating a company’s historical performance, staff turnover, and maintenance schedules. On-time delivery is also vital, with metrics such as On-Time In-Full (OTIF) measurement standards providing insights into a company’s logistics capabilities.

By following the guidelines outlined in the preceding sections, companies can develop a comprehensive understanding of their potential partners’ strengths and weaknesses. This enables them to make informed decisions and establish successful partnerships with food production companies that drive business success.

FAQ

What are the key factors to consider when evaluating food production companies?

When evaluating food production companies, key factors to consider include production capacity, quality control systems, reliability indicators, and on-time delivery track record.

What is the difference between co-packers and co-manufacturers in the food industry?

Co-packers typically package products for other companies, while co-manufacturers produce products from raw materials according to a company’s specifications.

How can I assess the manufacturing capacity of a food production company?

To assess manufacturing capacity, evaluate equipment capabilities, production line efficiency metrics, capacity planning, and demand forecasting.

What is the importance of FSMA compliance in food production?

FSMA compliance is crucial for ensuring food safety, and it involves implementing preventive controls, maintaining records, and undergoing regular inspections.

How can I evaluate the reliability of a food production partner?

To evaluate reliability, analyze historical performance, assess staff turnover and training programs, review maintenance schedules, and evaluate contingency planning.

What is On-Time In-Full (OTIF) delivery, and why is it important?

OTIF delivery refers to the ability of a supplier to deliver products on time and in full. It is crucial for maintaining a smooth supply chain and ensuring customer satisfaction.

How can I develop an effective supplier scorecard for food manufacturers?

To develop an effective supplier scorecard, select relevant KPIs, establish quality and compliance scoring methods, and implement regular performance reviews.

What are the essential elements of a food safety plan?

A food safety plan should include preventive controls, hazard analysis, and procedures for maintaining records and undergoing regular inspections.

How can I conduct a comprehensive food manufacturing audit?

To conduct a comprehensive audit, develop an audit checklist, schedule audits, identify common compliance red flags, and implement post-audit action plans.

What are the key considerations when negotiating contracts with food production companies?

When negotiating contracts, consider essential contract elements, service level expectations, pricing models, and risk allocation provisions.

How can I ensure effective traceability and recall readiness in food production?

To ensure effective traceability and recall readiness, implement FSMA 204 traceability requirements, develop recall plans, and conduct mock recalls.

What is the importance of sanitation and allergen control in food production?

Sanitation and allergen control are crucial for preventing contamination and ensuring food safety. Implement SSOPs, allergen control programs, and environmental monitoring.

How can I evaluate the quality management system of a food manufacturer?

To evaluate a quality management system, assess quality assurance and quality control processes, statistical process control implementation, and continuous improvement programs.

How small can my first run be?

Some food production companies will accept small pilots, but the smallest economic run is usually determined by changeover time, packaging minimums, and scheduling priorities, so expect pricing to improve as repeatability and forecast confidence improve. USDA Value-Added Producer Grants (VAPG) program overview

How do I know whether FDA or USDA rules apply?

The quickest way to avoid confusion with food production companies is to identify whether your product falls under FSIS inspection (meat, poultry, certain egg products) or FDA oversight, and then align labeling, processes, and inspections accordingly. USDA FSIS state inspection programs overview

What should I request before I visit the facility?

Before touring food production companies, ask for a document pack: capabilities statement, process flow, food safety plan summary, allergen program overview, traceability approach, complaint trend summary, and a simple business continuity outline so you can use site time to verify, not discover basics.

What delivery metrics should I put in the contract?

Instead of vague promises, food production companies should commit to measurable performance such as on-time ship date, order accuracy, temperature documentation for applicable products, and a clear process for exceptions and corrective actions when a shipment misses the window.

What’s a red flag that the plant isn’t truly ready?

A major red flag for food production companies is reluctance to show sanitation procedures, verification records, and who owns deviation decisions, because readiness is demonstrated through controlled routines rather than confident talk. FSIS Sanitation SOP guide (PDF)

Conclusion: Food Production Companies US

If you’re a U.S. grower, rancher, or emerging food brand, choosing food production companies is one of the highest-leverage decisions you’ll make because it determines whether your product ships safely, legally, and consistently when buyers reorder. FDA Food Safety Modernization Act (FSMA) overview

This guide shows a practical, operations-first way to compare food production companies using measurable criteria: line capacity, changeover realities, quality systems, transportation controls, and the proof behind “we can deliver on time.”

Start with the right definition of “capacity”

Capacity is not just “how many cases per day” for food production companies, but whether the facility’s regulatory category, equipment, and process controls match your product’s risk profile (acidified, low-acid canned, refrigerated, allergen-heavy, meat/poultry, etc.). 21 CFR Part 117 (CGMPs and preventive controls)

Reliability is the ability of food production companies to repeat the same result run after run, which depends on standardized work, training, maintenance discipline, and a management system that catches drift before customers do. NIST Manufacturing Extension Partnership (MEP) overview

What “on-time delivery” actually measures in the real world

On-time performance for food production companies is a chain outcome: accurate forecasting, achievable lead times, schedule stability, picking accuracy, carrier capacity, and receiving appointments that don’t collapse under detention and dock delays. FSMA Sanitary Transportation rule page (FDA)

When buyers say “on time,” they often mean the shipment hits a narrow appointment window with correct quantities and correct labels, so food production companies must build delivery readiness into planning rather than treating it as a shipping department problem.

Step 1: Lock your requirements before you contact anyone

Before you shortlist food production companies, write a one-page “definition of done” that includes target pack sizes, expected shelf-life, storage conditions, allergens, and label claims that matter to your buyers. FDA Nutrition Facts label overview

Then translate that into acceptance criteria for food production companies: critical limits (where relevant), sensory boundaries, defect tolerances, case/pallet configuration, and a delivery promise stated as a metric you can audit later. FSIS guideline for label approval (overview)

Step 2: Build a compliant shortlist the fast way

For FDA-regulated products, confirm the facility identity and registration details early because reputable food production companies should be able to point to their facility registration information and inspection readiness without hesitation.

If your product includes meat, poultry, or certain egg products, verify that food production companies operate under the correct inspection framework and understand what “inspection” means for your specific product category. USDA FSIS inspection programs overview

For farm-grown inputs and fresh handling steps, ask food production companies how they manage farm-to-facility risk using recognized Good Agricultural Practices and documented supplier approval rather than informal “we know our farms” assurances. USDA AMS GAP/GHP audit program

Step 3: Evaluate capacity like an operations manager

Ask food production companies for a “capacity map” that lists each relevant line, its nominal throughput, typical OEE constraints, and the changeover time between your SKU family and the runs before and after it. NC State Extension guide on choosing a copacker

Capacity isn’t usable if downtime is chronic, so request evidence that food production companies run preventive maintenance, track unplanned stoppages, and have spare-parts discipline for the equipment that would stop your product from shipping. OSHA Severe Injury Prevention fact sheet

Labor is a hidden bottleneck, so ask food production companies how they staff peaks, cross-train for sanitation and changeovers, and protect your slot when the facility is short-handed or competing priorities hit the schedule. NIST MEP example of quality management improving operations

Step 4: Reliability is built on systems, not promises

Reliable food production companies can show a documented food safety plan (or HACCP-based system where applicable), hazard analysis logic, preventive controls, monitoring records, corrective actions, and verification that proves the system works day-to-day. FDA guidance page on hazard analysis and preventive controls

For inspected meat and poultry operations, reliability means the HACCP plan is validated and supported with data, so food production companies should be comfortable walking you through validation support, ongoing verification, and how they manage deviations without hiding them. FSIS HACCP validation guidance

Certifications don’t replace due diligence, but they can standardize expectations, so ask food production companies what management system standard they use, how internal audits are handled, and who owns continuous improvement when a KPI slips. ISO 22000 food safety management systems overview

Step 5: On-time delivery depends on cold chain discipline

If your product is temperature-sensitive, evaluate food production companies on their ability to protect time/temperature from pack-out to carrier handoff, including pre-cooling, dock procedures, trailer checks, and documented corrective actions for excursions. FDA Sanitary Transportation rule page

Carrier availability and transit variability are real, so food production companies should be able to explain how they plan around appointment windows, driver limits, detention risk, and contingency routing when lanes tighten. FMCSA Hours of Service (HOS) Federal Register notice

Step 6: Traceability and recall readiness protect your brand

Traceability expectations are rising, and food production companies should show how they capture key data elements and critical tracking events so a lot can be traced forward and backward quickly without “we’ll pull it from emails.” FDA FSMA final rule on additional traceability records

Ask food production companies to walk you through a mock recall: who is on the team, how lots are isolated, how customers are notified, and how effectiveness checks are documented rather than assumed. FDA recalls, market withdrawals, and safety alerts hub

Quick checklist

Use this checklist to compare food production companies quickly, then score each item as Green/Yellow/Red to keep decisions objective when sales conversations get persuasive. UF/IFAS guidance on finding and using a copacker

- Regulatory fit confirmed (FDA vs. FSIS) and product category experience documented

- Written capability statement that matches your process (thermal, refrigerated, frozen, fermentation, etc.)

- Capacity map for your SKU family (throughput, changeover time, sanitation windows)

- Food safety plan readiness (hazards, controls, monitoring, corrective actions, verification)

- Allergen segregation plan (storage, rework control, label checks, sanitation validation)

- Traceability system that can produce lot genealogy quickly (inputs to finished goods)

- Delivery model defined (lead time, ship days, appointment management, carrier strategy)

- Quality release method stated (hold-and-release rules, COAs where relevant, disposition authority)

- Escalation process for issues (who decides, timeline, documented communication)

- Business continuity basics (backup equipment, alternate suppliers, outage response)

Common mistakes to avoid

Most problems with food production companies are predictable, and you can prevent them by insisting on evidence, aligning incentives, and piloting before you scale. Oregon Department of Agriculture guidance on working with co-packers (PDF)

- Choosing on price alone: Prevent it by scoring total cost of failure (chargebacks, rework, lost slots) and requiring a pilot run before long commitments.

- Skipping a documented spec: Prevent it by issuing a controlled spec sheet and a clear change-control process for ingredients, packaging, and process settings.

- Assuming certifications equal performance: Prevent it by auditing the KPIs you care about (scrap, deviations, complaint trends) and reviewing corrective actions.

- Ignoring changeovers and sanitation: Prevent it by estimating true run time (including washdowns) and setting realistic lead times around the facility master schedule.

- Unclear ownership of quality release: Prevent it by defining who can release, who can hold, and what triggers automatic holds.

- Weak packaging reality checks: Prevent it by testing packaging under real distribution conditions (compression, vibration, temperature swings) before full launch.

- No plan for supply disruptions: Prevent it by approving alternates for key inputs and documenting substitution rules that protect label compliance.

- Overpromising to retailers: Prevent it by matching commitments to proven throughput and putting buffer into launch timelines.

Costs and ROI snapshot

Cost comparisons across food production companies should start with the drivers that actually move the number: certification and audit cadence, lab testing frequency, allergen controls, packaging complexity, and sanitation time that reduces available run hours. GFSI Benchmarking Requirements implementation handbook (PDF)

For many U.S. value-added projects, ROI improves when food production companies help you reduce risk costs—label errors, allergen cross-contact, and complaint-driven returns—because a single preventable issue can erase months of margin. FDA food allergies and major allergens overview

If you’re building or expanding a facility relationship, don’t ignore environmental compliance costs because food production companies operating under industrial permits may require documented controls for stormwater and site practices that influence timelines and operating budgets. EPA overview of stormwater discharges from industrial activities

Final thought

The best partnerships with food production companies are built when you verify capability with evidence, pilot before scaling, and manage the relationship using shared metrics that protect food safety, brand trust, and delivery performance at the same time.

Sources & References

- FDA: FSMA rules and guidance for industry

- FDA: FSMA Produce Safety rule overview

- FDA: Food Traceability List (FSMA 204)

- FDA: FSMA Food Traceability Rule FAQs

- FDA: Food Code (retail/foodservice best-practices model)

- FDA: Food Labeling Guide (PDF)

- FDA: Food defense training for the Intentional Adulteration rule

- eCFR: 21 CFR Part 121 (Intentional Adulteration / mitigation strategies)

- USDA FSIS: HACCP guidance hub

- USDA FSIS: Labeling and label approval guidance hub

- USDA FSIS: Small Plant Help Desk

- USDA FSIS: Safe and suitable ingredients directive

- USDA AMS: Product specifications and requirements

- SQFI: Library of SQF codes

- BRCGS: Global Standard Food Safety (Issue 9) product page

- ISO: ISO 9001 quality management systems standard overview

- GFSI: Certification programme recognition overview

- EPA: Food Contact Sanitizing Solutions Model (FCSSM)